JimInOz

··Melbourne AustraliaAnybody come across one of these?

Some time ago I got an alarm pocket watch from a friend of a friend who needed to get it fixed as it wasn't working properly.

I explained that a 75 year old pin lever, stamped plate movement wasn't exactly designed to last as long as a quality Swiss movement.

However, I did my best and got it running/functioning.

Some months later, I got a call, "the hands are not turning, can you fix it"...........

This is despite telling the owner that while it worked when I finished it, the watch should not be used as a reliable timekeeper but put on the display shelf as a vintage curio.

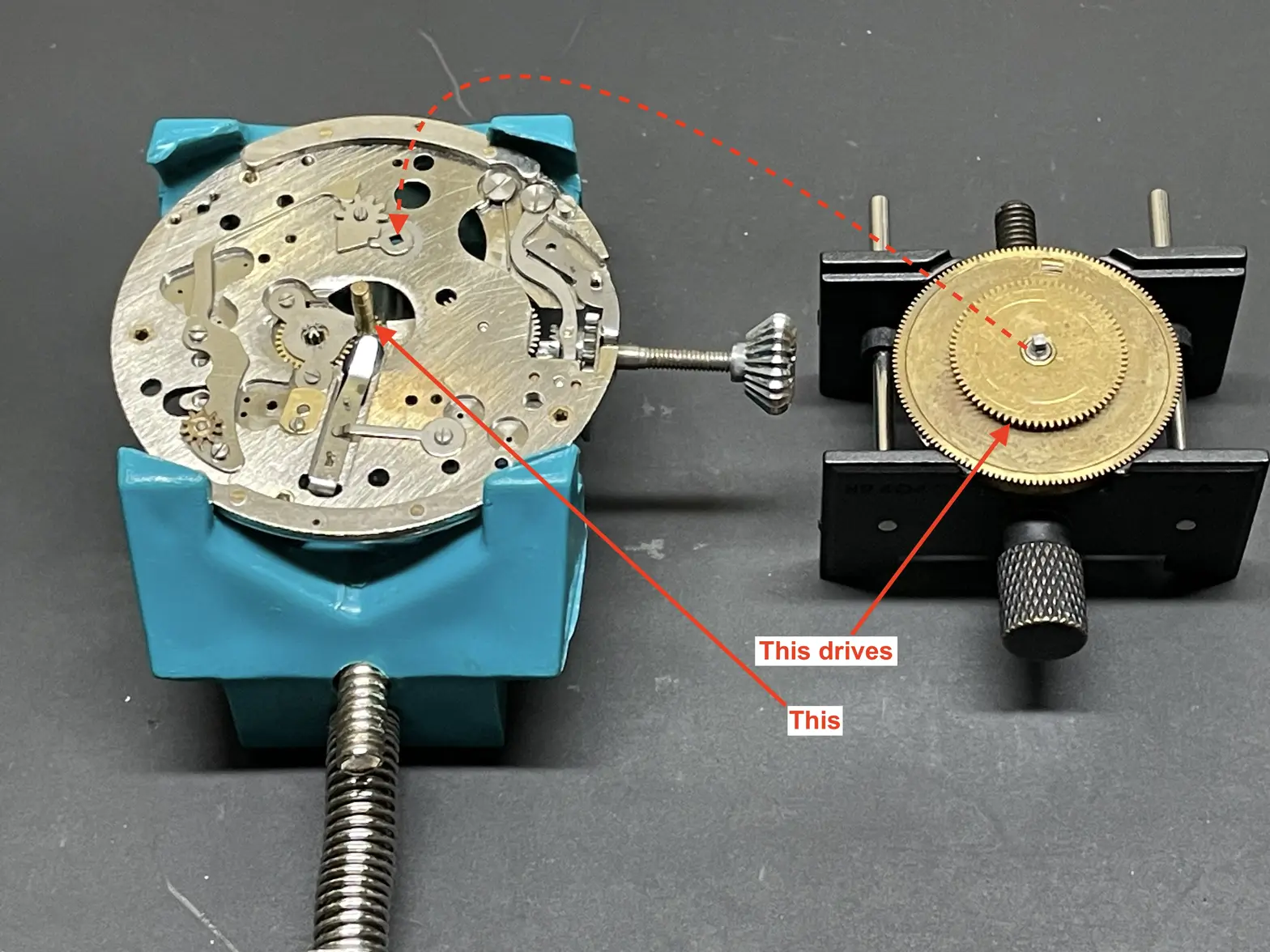

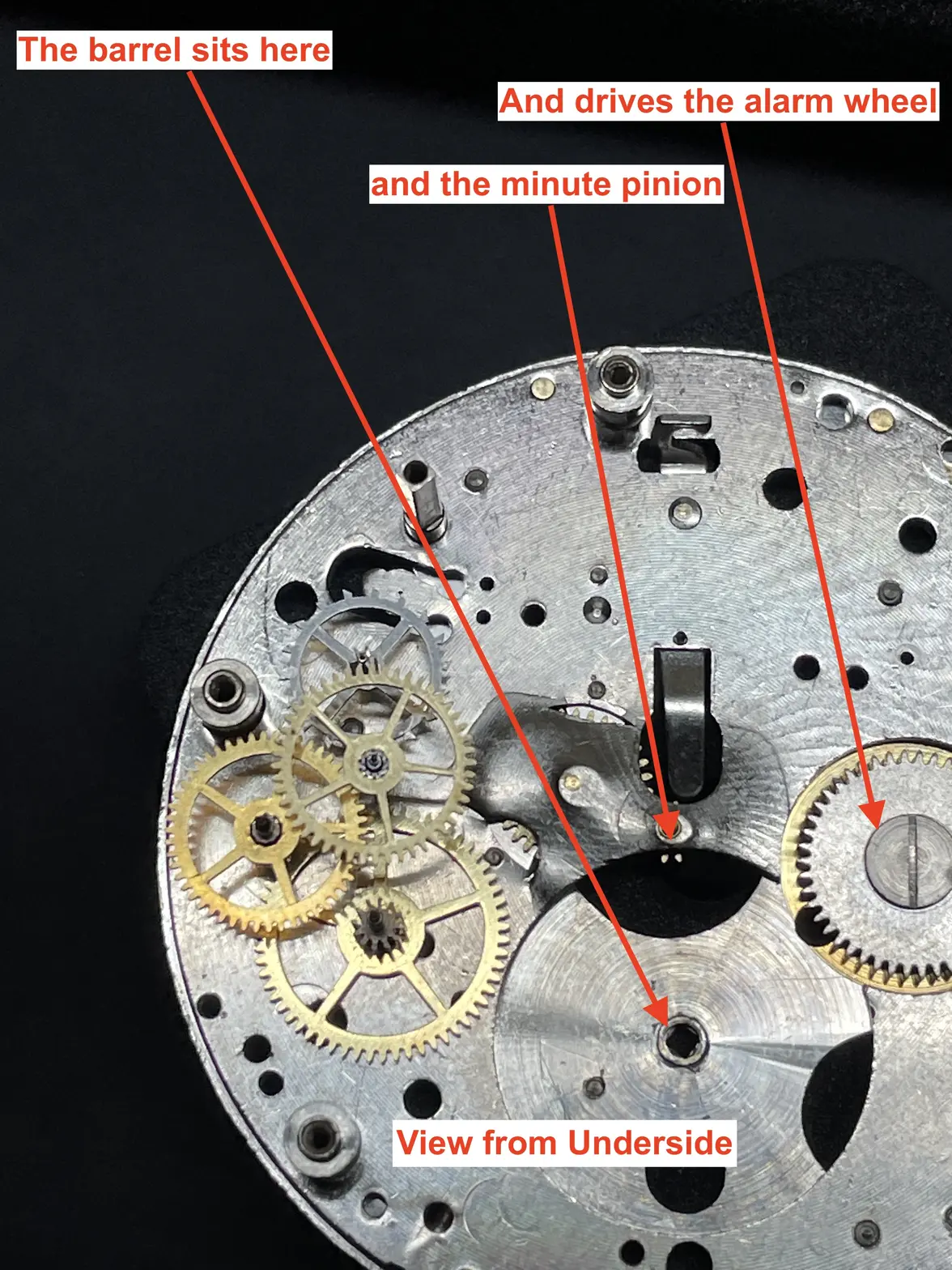

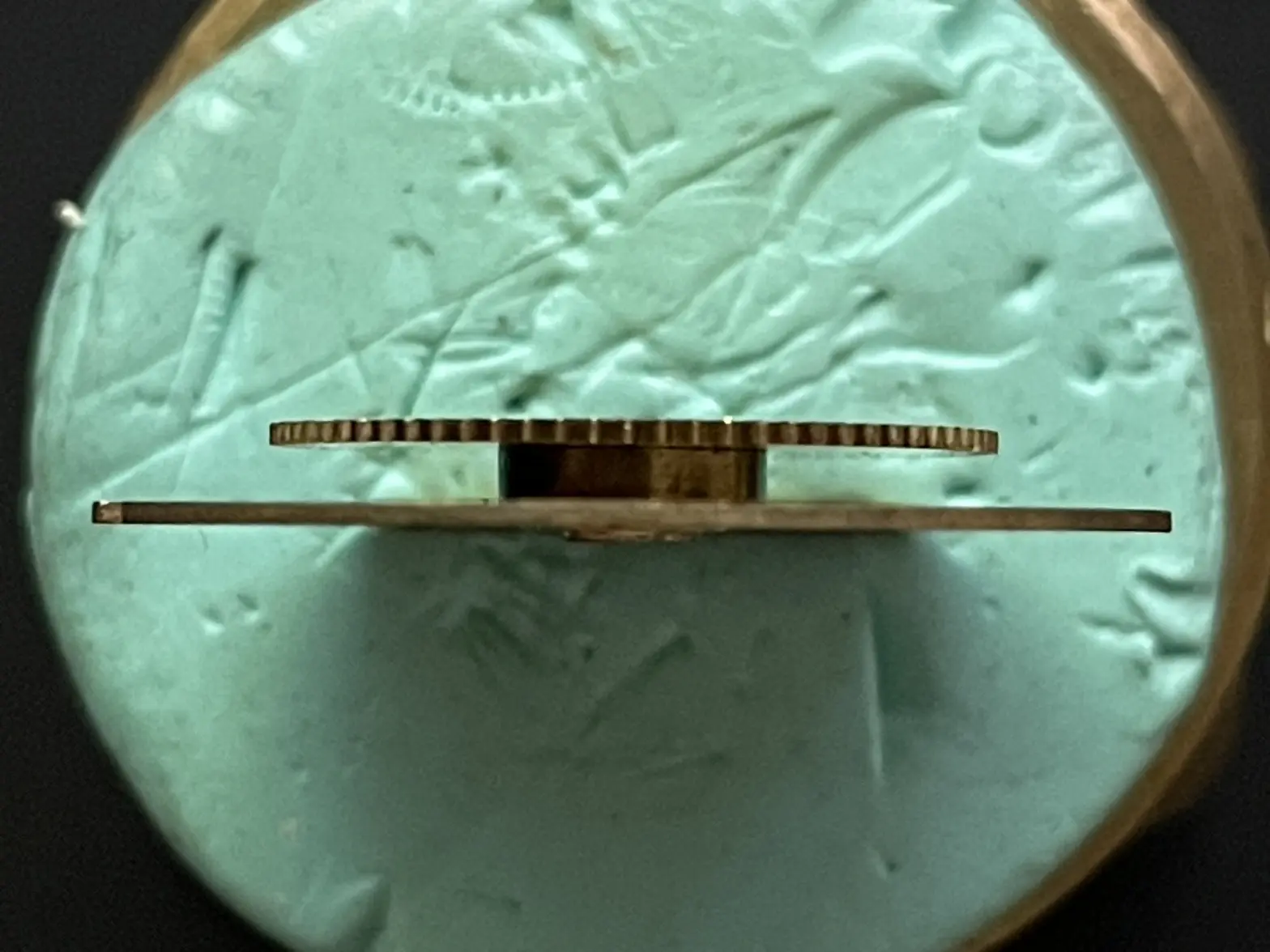

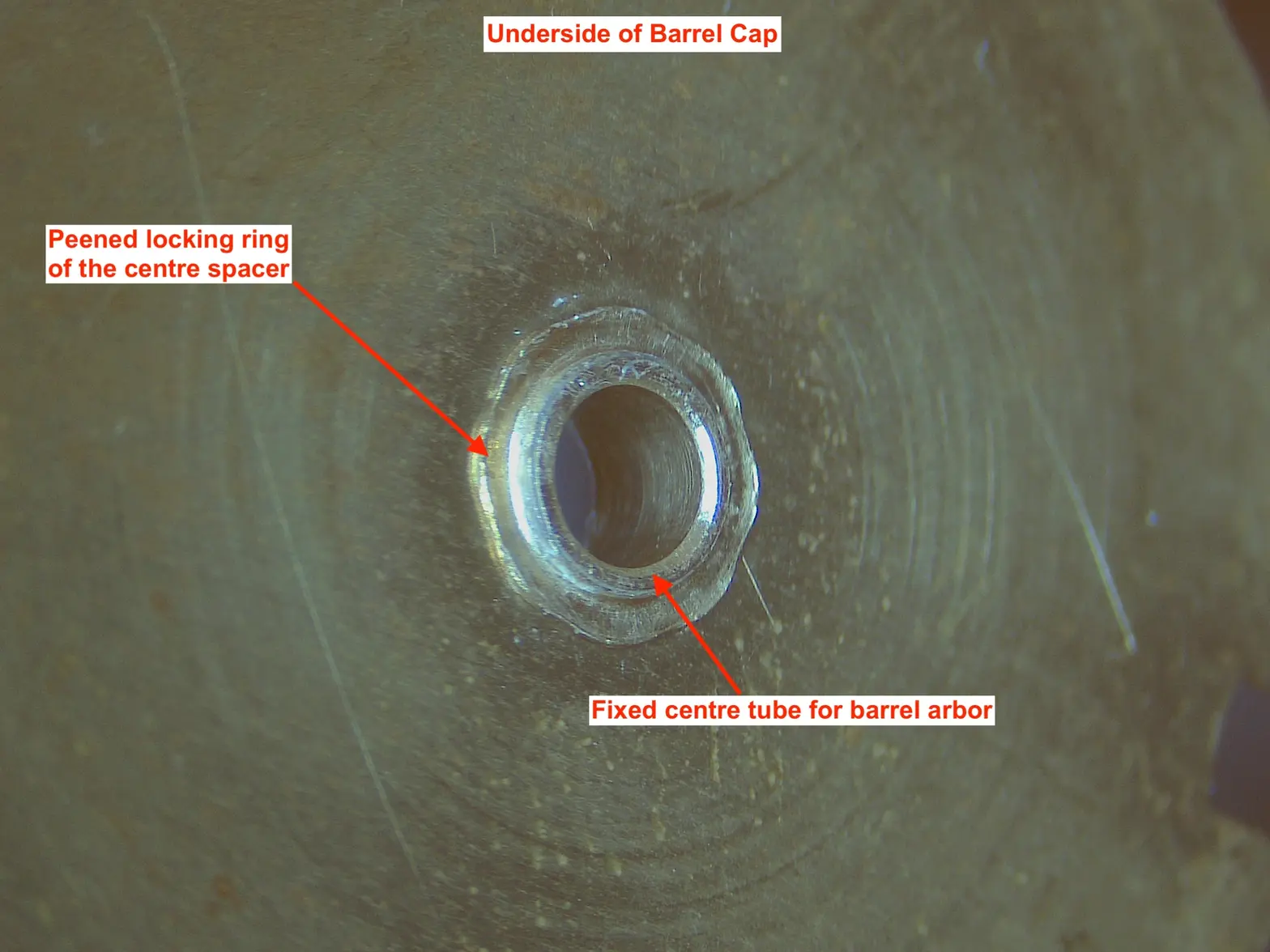

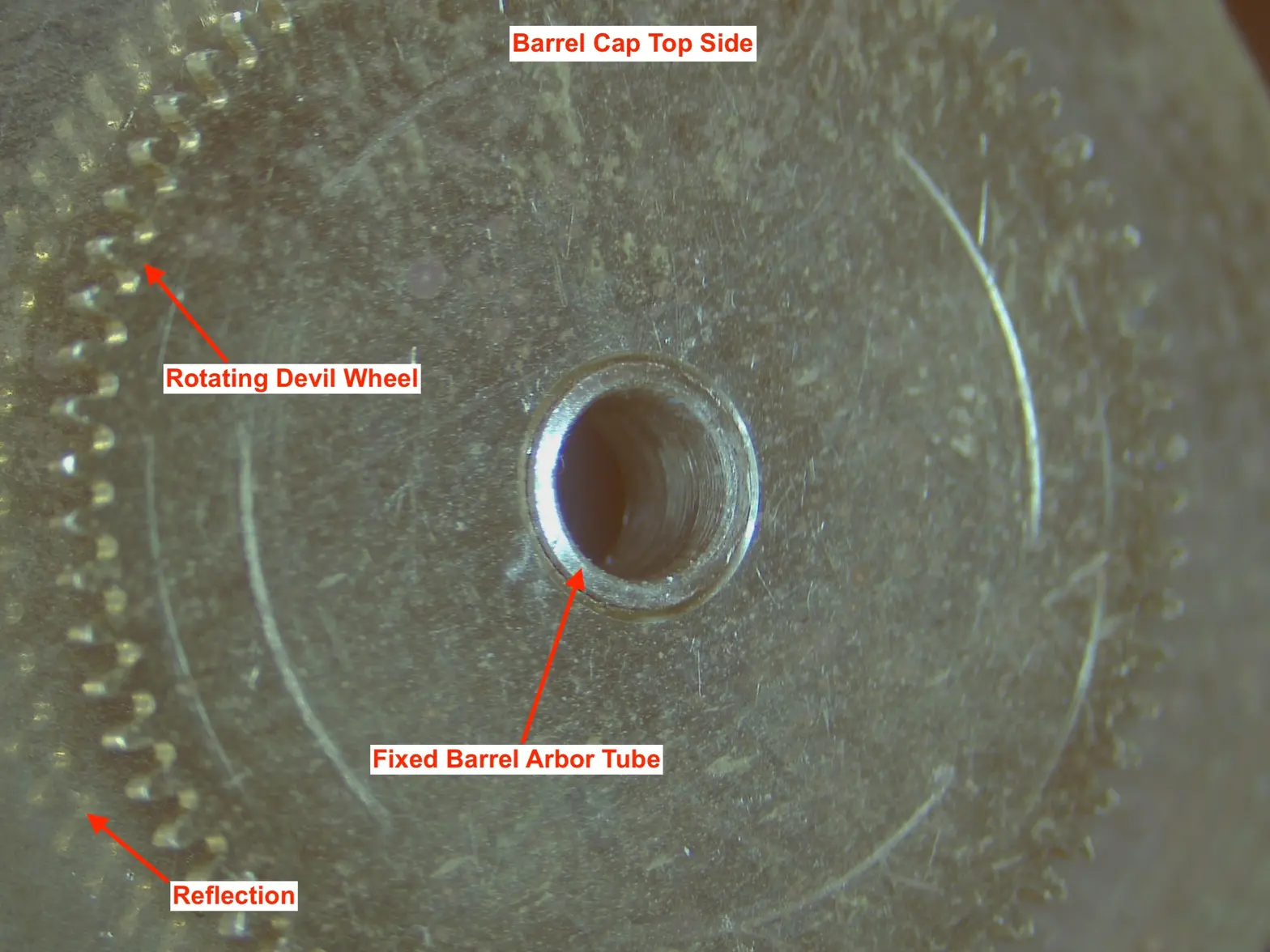

Anyway, it's back. The problem is the method of drive from the mainspring barrel to the hands.

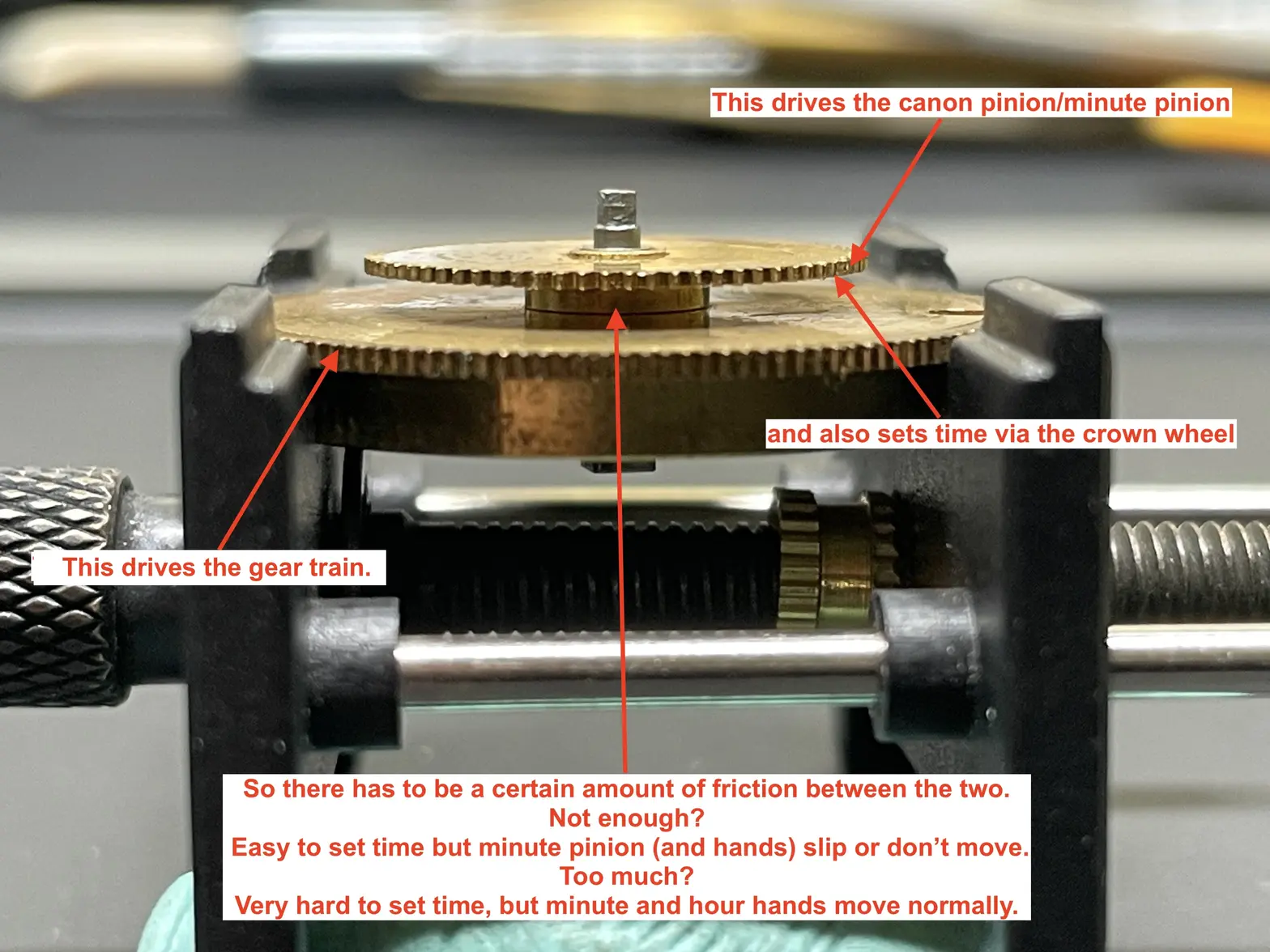

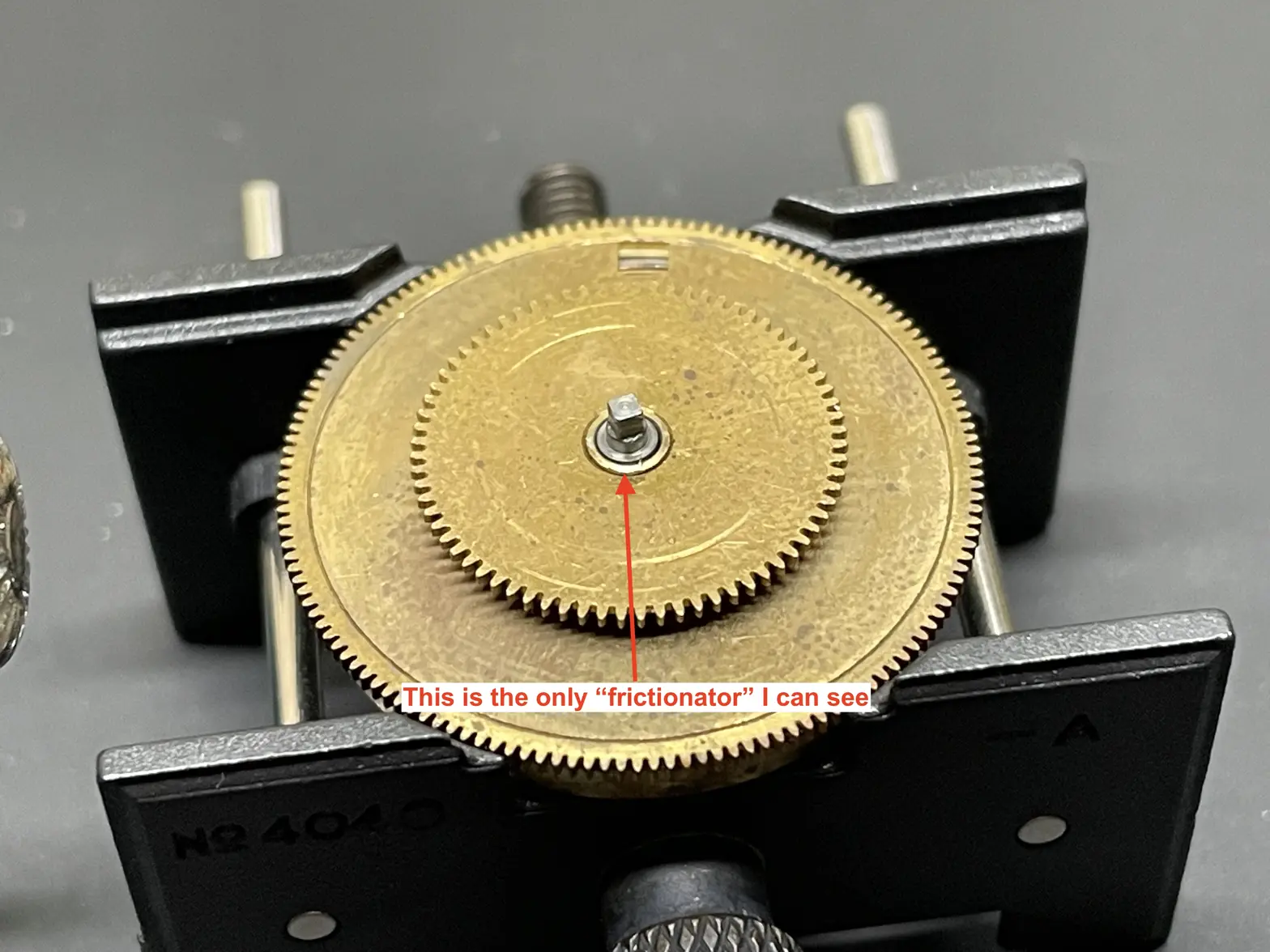

Unlike a standard gear train, the mainspring barrel only drives the gear train from the barrel to the escape wheel and the time keeping/setting is driven by a friction wheel fitted to the top of the main barrel.

Over time, the "friction" that was between the two components has deteriorated due to wear, primarily because the time setting from the crown wheel to the minute pinion must turn the "friction wheel".

I think I can restore the friction by using a dome punch on an anvil and hopefully strike a balance between 50/50 friction, enough to drive the hands against the drag of the alarm wheels and enough to allow setting the time without twisting the stem into a liquorice stick.

Photos follow to explain things.

Any hints or tips as to resolve this issue?

Some time ago I got an alarm pocket watch from a friend of a friend who needed to get it fixed as it wasn't working properly.

I explained that a 75 year old pin lever, stamped plate movement wasn't exactly designed to last as long as a quality Swiss movement.

However, I did my best and got it running/functioning.

Some months later, I got a call, "the hands are not turning, can you fix it"...........

This is despite telling the owner that while it worked when I finished it, the watch should not be used as a reliable timekeeper but put on the display shelf as a vintage curio.

Anyway, it's back. The problem is the method of drive from the mainspring barrel to the hands.

Unlike a standard gear train, the mainspring barrel only drives the gear train from the barrel to the escape wheel and the time keeping/setting is driven by a friction wheel fitted to the top of the main barrel.

Over time, the "friction" that was between the two components has deteriorated due to wear, primarily because the time setting from the crown wheel to the minute pinion must turn the "friction wheel".

I think I can restore the friction by using a dome punch on an anvil and hopefully strike a balance between 50/50 friction, enough to drive the hands against the drag of the alarm wheels and enough to allow setting the time without twisting the stem into a liquorice stick.

Photos follow to explain things.

Any hints or tips as to resolve this issue?

Edited: