Speedmaster 105.012 Pushers - repairable?

wsfarrell

·What's the tool called?

ChrisN

·Now the next quest - how to take them apart without damaging the shoulder and button...

I suppose if your existing pusher is unserviceable and you think you might get somewhere with it, the following might help but, these parts are quite small and you might struggle so a watchmaker would be better. I believe you are very likely to end up with a completely broken pusher so, if the pusher works today, I would not try this yourself. Similar to the pictures above, here is a broken pusher and the cap is missing, as is the seal.

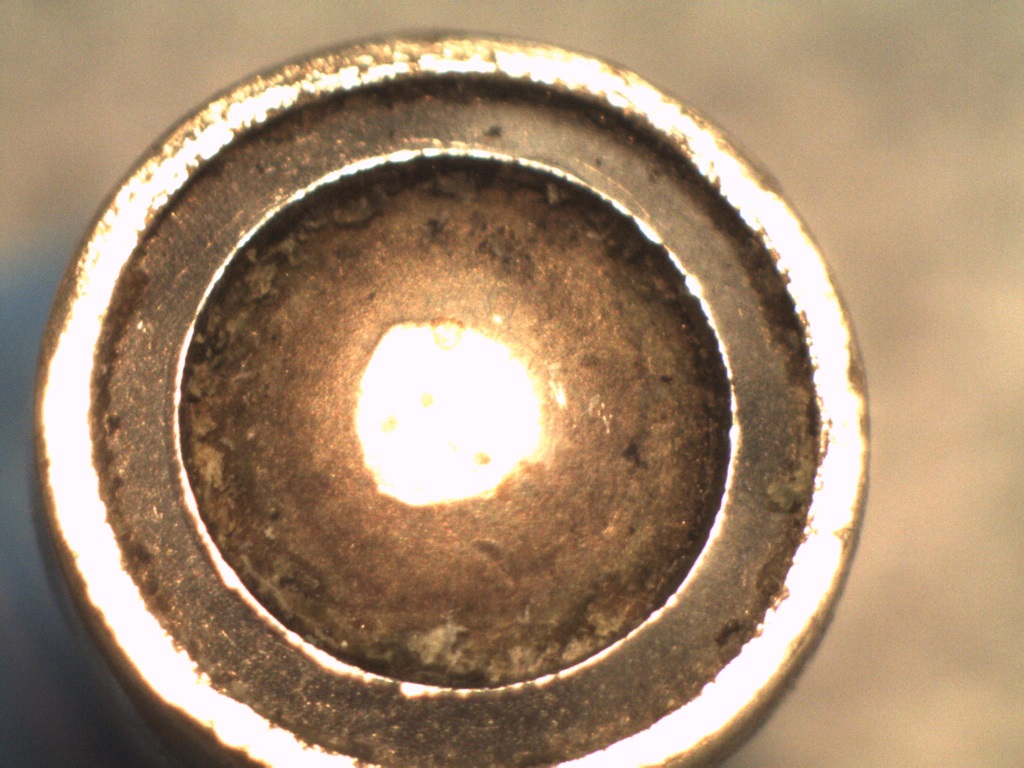

If I look at the ring (washer) in cross section, you'll see a leading chamfer.

Here is an intact pusher and you can see the ring is held in the pusher cap.

Here, I've added the other ring on top so you can see the relative diameters.

Initially, I would have thought that the caps were swaged or crimped onto the ring but looking at picture of @michael e and my two above, it seems there is a groove in the cap and the cap and ring are pressed together so the cap is held by the interference of the ring in the cap. That would explain the chamfer on one side of the ring as it would be that side that is pressed in to the cap and the chamfer gives a "lead in". By the way, that would also explain why so many of these are missing the cap...

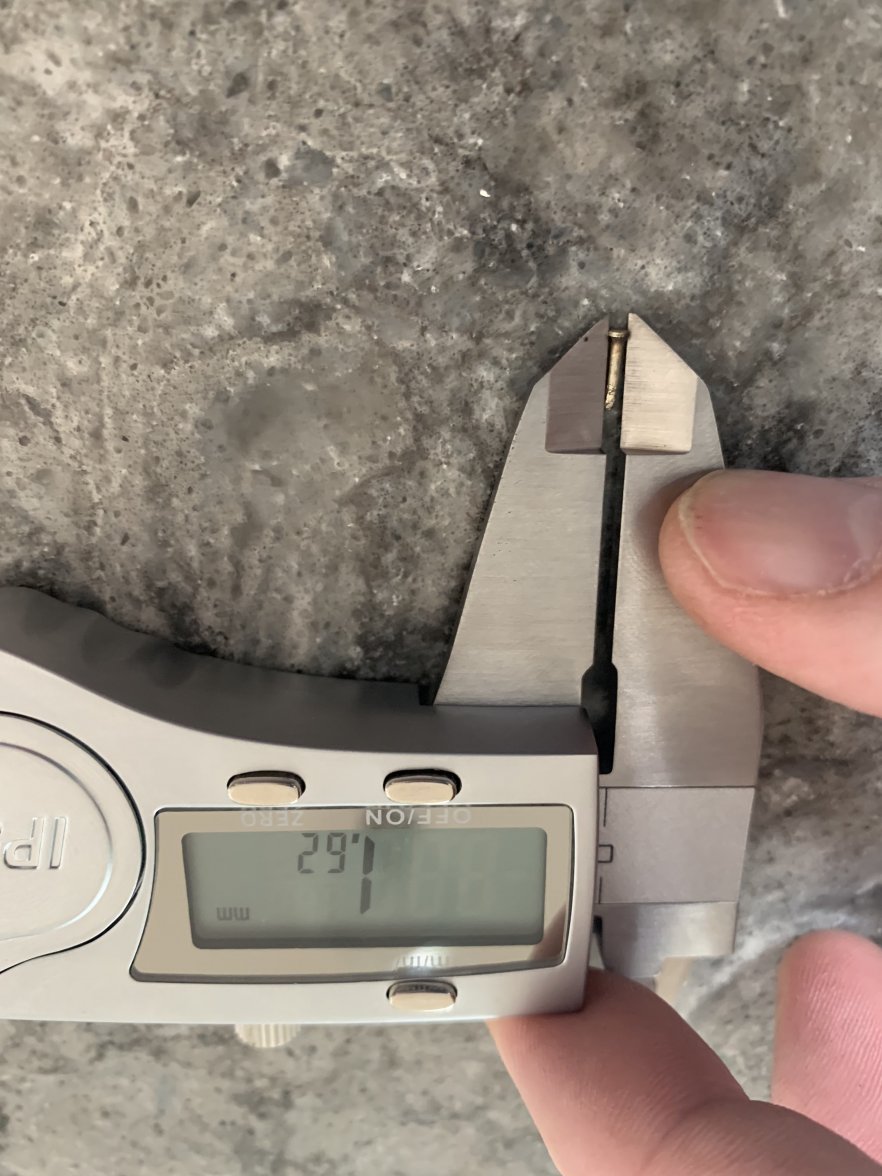

If you want to remove the cap, don't press on the pusher as it won't go far enough to remove the cap (see below). The only way I see is to put the pusher into a plate with a hole where the hole is just slightly larger than the outer diameter of the ring so the hole supports the circumference of the cap. Then grip the pusher part that goes in the case (the part of 2.5 mm diameter) with a pin vice and pull the pusher through the hole in the plate which should separate the ring from the cap. Then you'll end up with my first picture, but also a cap.

Now the problems start again. The pusher is a sealed unit and again has a ring to hold it all together - I am pretty sure this is swaged but it might be an interference fit again. You can see there is a wide washer below and you'll need to separate this from the pusher body to get to the internals - unless just replacing the gel seal that Michael shows resolves your issue - I don't see it will but, you can find out.

Re-fitting the ring to the cap is easy enough but, it will probably never be fully tight again unless you have a means to tighten the fit. At any point, it could separate and you'll lose the cap so, be aware of that.

Hope this helps, Chris

athom

·interesting thread in any case!

ChrisN

·That was quick. Check the orientation of the chamfer on the ring for future reference.

What's the plan now?

Cheers, Chris

What's the plan now?

Cheers, Chris

BatDad

·Yah that was the first thing I looked at when I pulled the ring out. That pic was really helpful! Thank you!

The top of the assembly has movement.

Kids are up now - so all peices bagged for the mo. When I get some time I want to take a closer look at that gel seal. Ideally I’d love to replace the stem that I tore up earlier in the process. But that may not be possible easily if it’s a sealed unit.

My goal - try and get the pusher cap to only have up down movement on the shoulder. Even if it means having to buy a svc replacement.

But I’m learning a ton about this particular type of pusher as I go!

Thanks for all the help thus far folks.

The top of the assembly has movement.

Kids are up now - so all peices bagged for the mo. When I get some time I want to take a closer look at that gel seal. Ideally I’d love to replace the stem that I tore up earlier in the process. But that may not be possible easily if it’s a sealed unit.

My goal - try and get the pusher cap to only have up down movement on the shoulder. Even if it means having to buy a svc replacement.

But I’m learning a ton about this particular type of pusher as I go!

Thanks for all the help thus far folks.

ChrisN

·I'd be interested to see what the seal looks like if you take it off, with the dimensions.

I would tighten the cap a little in the ring area using a lathe collet but you may not have that option. That way the ring would grip again.

Not sure any parts will interchange with the narrow neck service pushers due to the narrower neck. If you're lucky, Al might see one at some point and could measure it. I have the wide neck pusher geometry, obviously.

I just looked again and the sealed part washer definitely seems swaged into the body - it's under significant load from the spring all the time so that would make sense. This may be very hard to separate but, I'll look again on Monday.

Enjoy the weekend. Chris

I would tighten the cap a little in the ring area using a lathe collet but you may not have that option. That way the ring would grip again.

Not sure any parts will interchange with the narrow neck service pushers due to the narrower neck. If you're lucky, Al might see one at some point and could measure it. I have the wide neck pusher geometry, obviously.

I just looked again and the sealed part washer definitely seems swaged into the body - it's under significant load from the spring all the time so that would make sense. This may be very hard to separate but, I'll look again on Monday.

Enjoy the weekend. Chris

BatDad

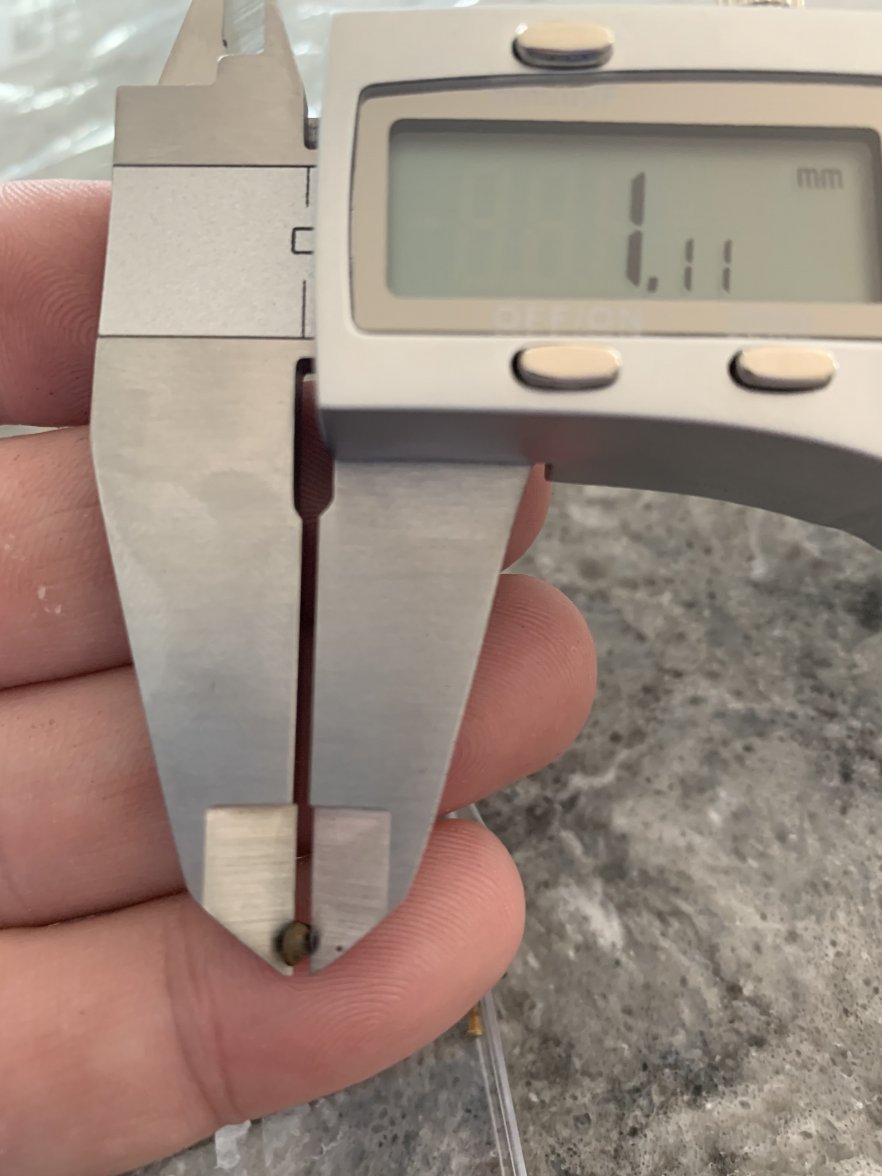

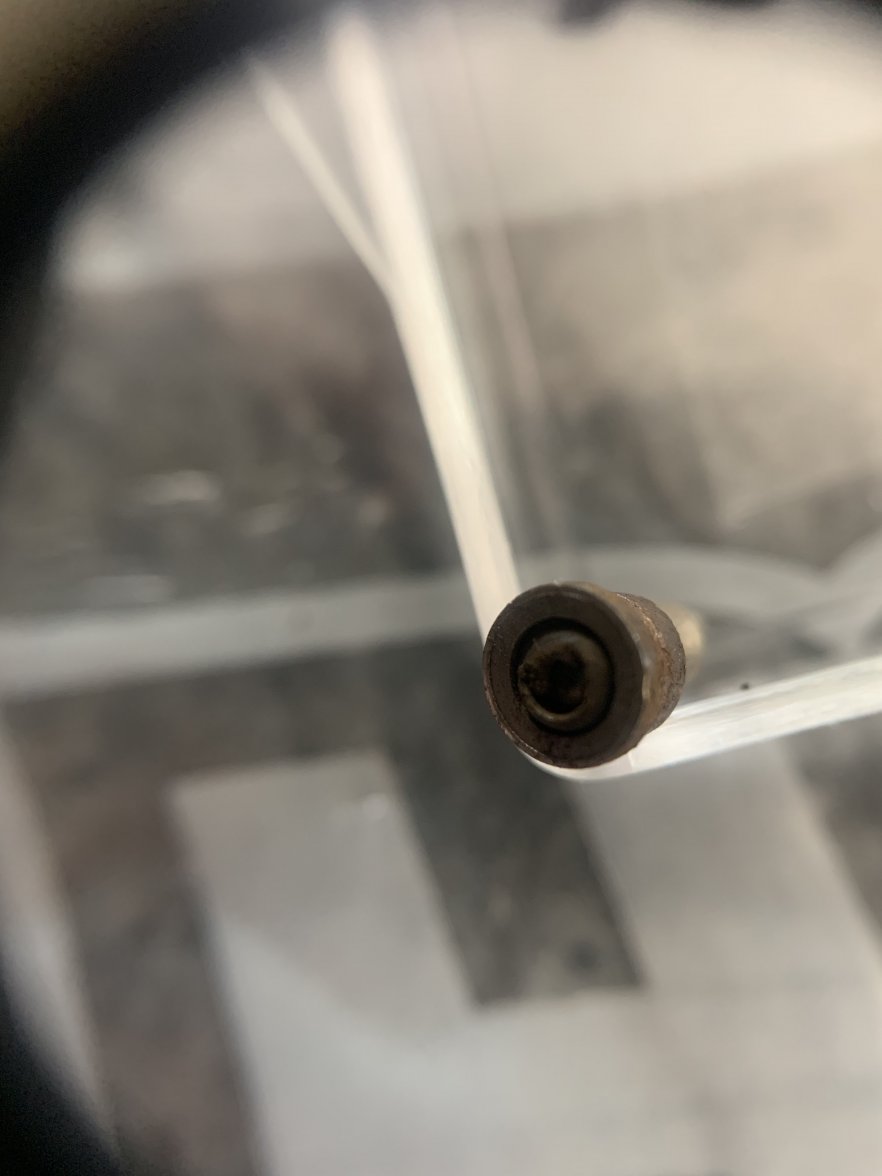

·Pushers are now disassembled.

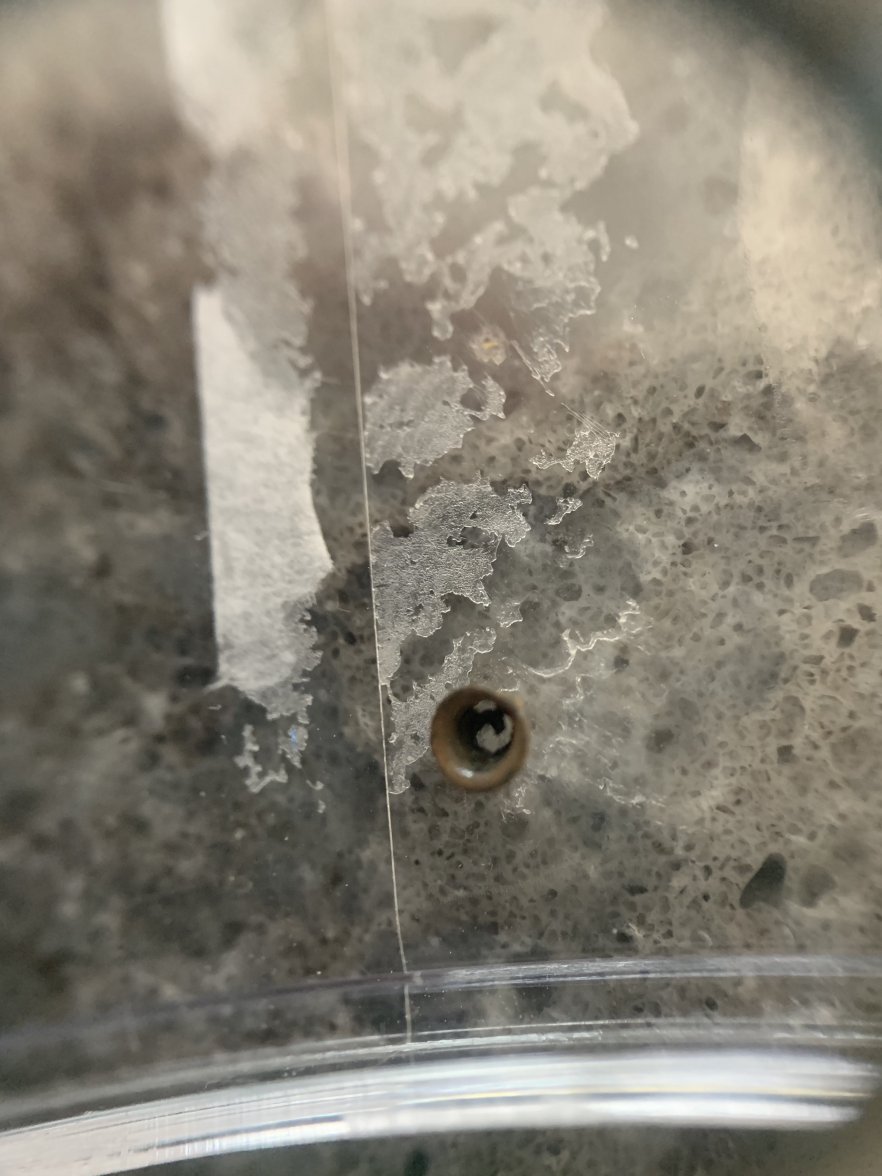

Interestingly the unit wasn’t sealed. There was a small rubber oring seal in one - in the other it had deteriorated badly -

In one pusher there was a broken spring. In the other no evidence of one at all. (Couldn’t have escaped - I did this in a transparent bag)

I’m taking this lack of springs as a serious contributing factor in the cap movement.

I have some donor pushers that I’m going to measure the stem and spring for.

Interestingly the unit wasn’t sealed. There was a small rubber oring seal in one - in the other it had deteriorated badly -

In one pusher there was a broken spring. In the other no evidence of one at all. (Couldn’t have escaped - I did this in a transparent bag)

I’m taking this lack of springs as a serious contributing factor in the cap movement.

I have some donor pushers that I’m going to measure the stem and spring for.

wsfarrell

·I'm surprised there doesn't seem to be more knowledge out there on these pushers, and I admire your willingness to repair, rather than replace. I would have given up and bought one of the easier-to-disassemble pushers by now.

https://www.ebay.com/itm/GENUINE-OM...724218&hash=item5921ffa4cd:g:aH4AAOSwOuRZrnxi

https://www.ebay.com/itm/GENUINE-OM...724218&hash=item5921ffa4cd:g:aH4AAOSwOuRZrnxi

This website may earn commission from Ebay sales.

ChrisN

·Interesting. Your pushers must have been apart before if the construction of the two is different and one is missing a spring. Thanks for the information on the seal, I'll bear it in mind.

How did you get the body apart? If the parts just came apart then I would definitely say someone has already tried to do something there.

These don't appear to be the wide neck pushers and look like service replacement parts. These are also not designed to be taken apart - at least that's what I would expect with interference fit pushers. If the pusher stem/bolt is screwed in to the cap of an interference fit pusher, I'd expect it to be loctited at the factory as you push these in already assembled, with the other side of the tool @BatDad is showing above. I can't see it well and there is no part number but I'm 99% sure it is not a wide neck.

Cheers, Chris

How did you get the body apart? If the parts just came apart then I would definitely say someone has already tried to do something there.

I'm surprised there doesn't seem to be more knowledge out there on these pushers, and I admire your willingness to repair, rather than replace. I would have given up and bought one of the easier-to-disassemble pushers by now.

https://www.ebay.com/itm/GENUINE-OM...724218&hash=item5921ffa4cd:g:aH4AAOSwOuRZrnxi

Cheers, Chris

This website may earn commission from Ebay sales.

BatDad

·How did you get the body apart? If the parts just came apart then I would definitely say someone has already tried to do something there.

The body for these two were basically just the shoulder, pin, spring and gasket/seal.

The amount of gunk/dirt looked consistent with age. No sign of being opened before but I also don’t have a plausible theory for where the spring is.

Ack on the skinny service replacements. I noticed the thread slot and thought the same. I am getting some 0089s if I can’t refit the wide necks.

I’m wondering if there are different types of press in pushers. Well, I’d suggest there are; the question is how many?

Edit - btw the construction of both pushers was the same. Just more deterioration in one of them

wsfarrell

·These don't appear to be the wide neck pushers and look like service replacement parts. These are also not designed to be taken apart - at least that's what I would expect with interference fit pushers. If the pusher stem/bolt is screwed in to the cap of an interference fit pusher, I'd expect it to be loctited at the factory as you push these in already assembled, with the other side of the tool @BatDad is showing above. I can't see it well and there is no part number but I'm 99% sure it is not a wide neck.

Given the screw slot in the bolt on the eBay pusher, I would think it would be designed to be taken apart. The loctite would be there so it wouldn't fall apart, but the slot is there so it can be unscrewed if necessary. No?

BatDad

·Am interested in this answer. If the slot did secure the cap, Itd mean that the caps were different for vintage and service. Despite the same manufacturing external specs for the case.

For ref the svc pushers I’m aware of for a 105.012 case are 086ST0007 and 086ST0089

5x2.7m cap

But afaik they are skinny shoulder.

For ref the svc pushers I’m aware of for a 105.012 case are 086ST0007 and 086ST0089

5x2.7m cap

But afaik they are skinny shoulder.

ChrisN

·I've asked the eBay seller for a part number. I also asked if he had in stock pusher # 086ST0088, which I understand is a correct 4.5 x 2.7 pusher for the 105.003.

Given the screw slot in the bolt on the eBay pusher, I would think it would be designed to be taken apart. The loctite would be there so it wouldn't fall apart, but the slot is there so it can be unscrewed if necessary. No?

The modern pushers are usually a completely different construction to the old ones. I know you will have the screw in pushers on other watches and those are fitted by unscrewing the bolt from the cap and then, using the correct tool that grips the splines of the pusher body, they're screwed to the case. Those body splines are also used by the cap as there are matching ones in the cap and they stop the cap rotating in use and when re-attaching the bolt. This design is fairly typical over the years.

I don't know how many modern types there are but, the press fit ones also often now have the splines to stop the cap rotating and so, for initial assembly, there is a slot in the bolt. Yes, you can take them apart but, why would you want to - they are designed to be fitted as an assembly. I have seen pictures where people have tried to take them apart and broken the bolt because of the loctite on the bolt thread in the cap so, I wouldn't recommend it.

Am interested in this answer. If the slot did secure the cap, Itd mean that the caps were different for vintage and service. Despite the same manufacturing external specs for the case.

For ref the svc pushers I’m aware of for a 105.012 case are 086ST0007 and 086ST0089

5x2.7m cap

But afaik they are skinny shoulder.

Cheers, Chris

wsfarrell

·Sorry, I got bogged down in 105's and was looking up 003 instead of 012. The 0089 part is correct.

BatDad

·All good @wsfarrell.

@ChrisN hear you on the swapping bits from other pushers thought.

I’m now actually wondering if I can order 1mm springs, and stems custom made from China. Am gonna sniff around on eBay a little later.

The experiment is now how to craft the pusher seal. Again - want to check if simple oring 1mm gap would work.

I’ll tinker on this and report bank with findings.

@ChrisN hear you on the swapping bits from other pushers thought.

I’m now actually wondering if I can order 1mm springs, and stems custom made from China. Am gonna sniff around on eBay a little later.

The experiment is now how to craft the pusher seal. Again - want to check if simple oring 1mm gap would work.

I’ll tinker on this and report bank with findings.

Edited:

ChrisN

·For the O rings, you can look at WIT who make various sets. They are Swiss so you have some guarantee of quality. Here's one set:

http://www.witschifils.ch/en/search_ref.php?ref=03665

Springs can usually be found in the west as well but, I've never needed them. Someone gave me some pointers at one point but I can't immediately recollect where.

Do you need new bolts/stems? A watchmaker could make them on a lathe but, expect to pay. If you have a relationship with a watchmaker, might be worth trying them.

The issue with Chinese parts is usually quality and the fact that you're fitting them to a Swiss watch so, people might look down on that solution. Most of us look down on non original parts but, in this case, where the parts are NLA, there should be lee way. It's a murky area which, to my mind, you offset if you're using Swiss parts.

Cheers, Chris

http://www.witschifils.ch/en/search_ref.php?ref=03665

Springs can usually be found in the west as well but, I've never needed them. Someone gave me some pointers at one point but I can't immediately recollect where.

Do you need new bolts/stems? A watchmaker could make them on a lathe but, expect to pay. If you have a relationship with a watchmaker, might be worth trying them.

The issue with Chinese parts is usually quality and the fact that you're fitting them to a Swiss watch so, people might look down on that solution. Most of us look down on non original parts but, in this case, where the parts are NLA, there should be lee way. It's a murky area which, to my mind, you offset if you're using Swiss parts.

Cheers, Chris