- Posts

- 5

- Likes

- 0

gszinyei

·Hi

I’m reaching out for help to resolve this mystery.

Given a Seamaster with this reference I bought some time ago for a project to work on.

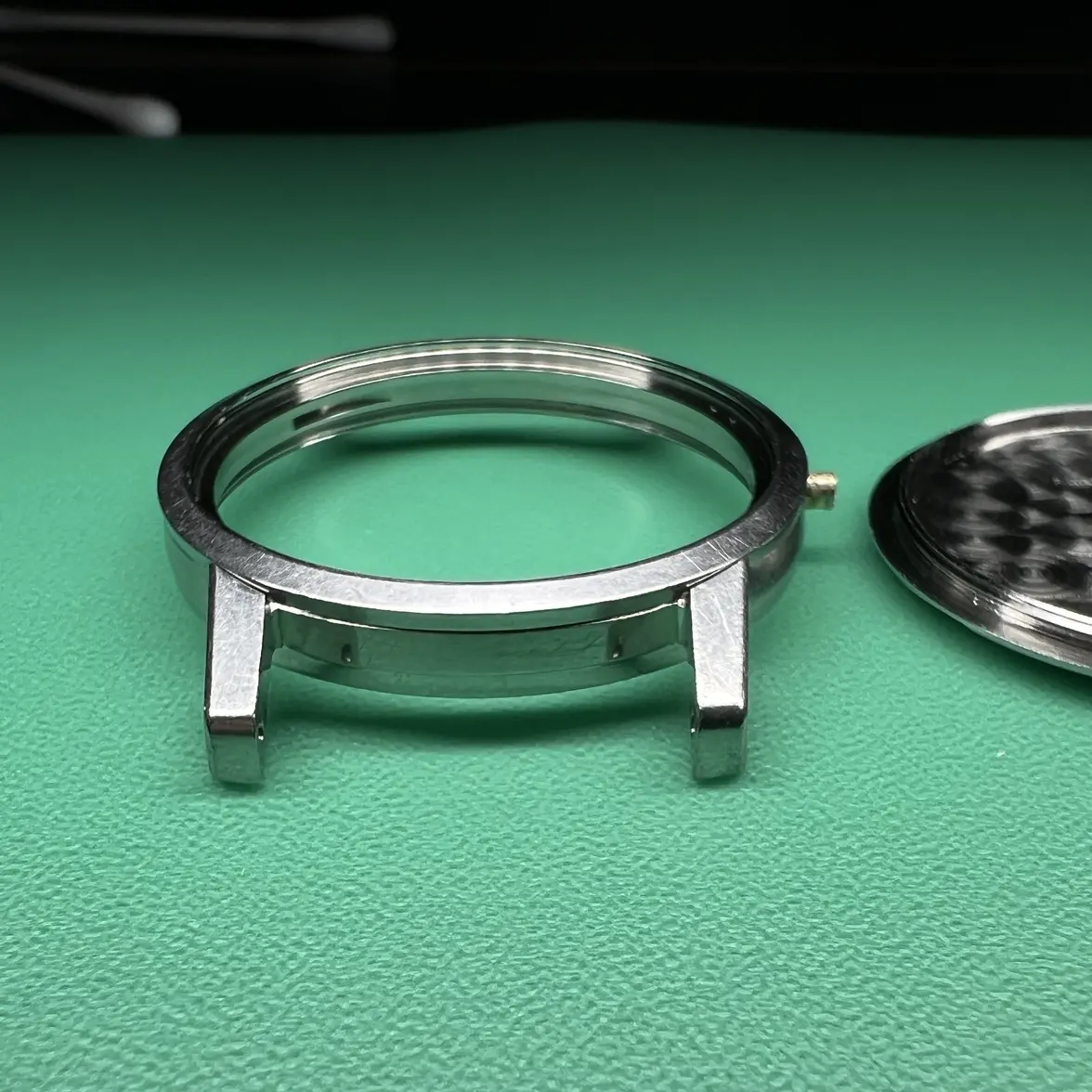

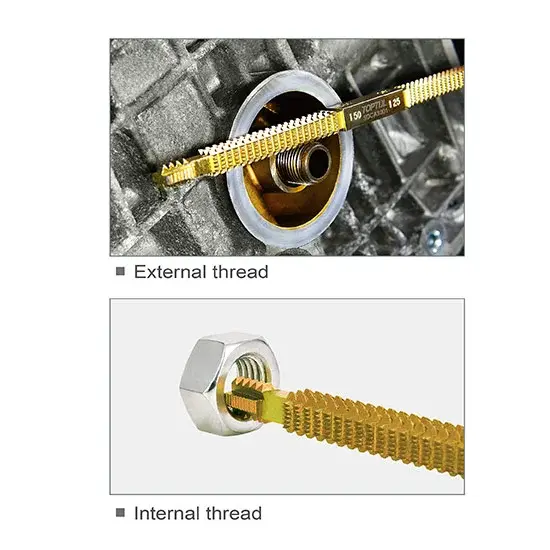

The watch was in one piece, no red flags as I could see. After dismantling and cleaning the case I’m no longer able to put the caseback back to the case. I know it sounds weird. I don’t recall removing the caseback was a problem at the first place. But I start to wonder it’s not the caseback for this case. I dealt with a good number of vintage Omega and never experienced such. Already when starting to screw the caseback, it doesn’t feel a good fit. Occasionally I can turn a few time but definitely not enough to close the case. Note the gasket has been removed but even so it’s far from a closed position.

Can someone help me review the case based and determine if I’m dealing with a franken case perhaps? I looked pictures of the same reference but it looks ok.

Thank you in advance!

I’m reaching out for help to resolve this mystery.

Given a Seamaster with this reference I bought some time ago for a project to work on.

The watch was in one piece, no red flags as I could see. After dismantling and cleaning the case I’m no longer able to put the caseback back to the case. I know it sounds weird. I don’t recall removing the caseback was a problem at the first place. But I start to wonder it’s not the caseback for this case. I dealt with a good number of vintage Omega and never experienced such. Already when starting to screw the caseback, it doesn’t feel a good fit. Occasionally I can turn a few time but definitely not enough to close the case. Note the gasket has been removed but even so it’s far from a closed position.

Can someone help me review the case based and determine if I’m dealing with a franken case perhaps? I looked pictures of the same reference but it looks ok.

Thank you in advance!