timoss

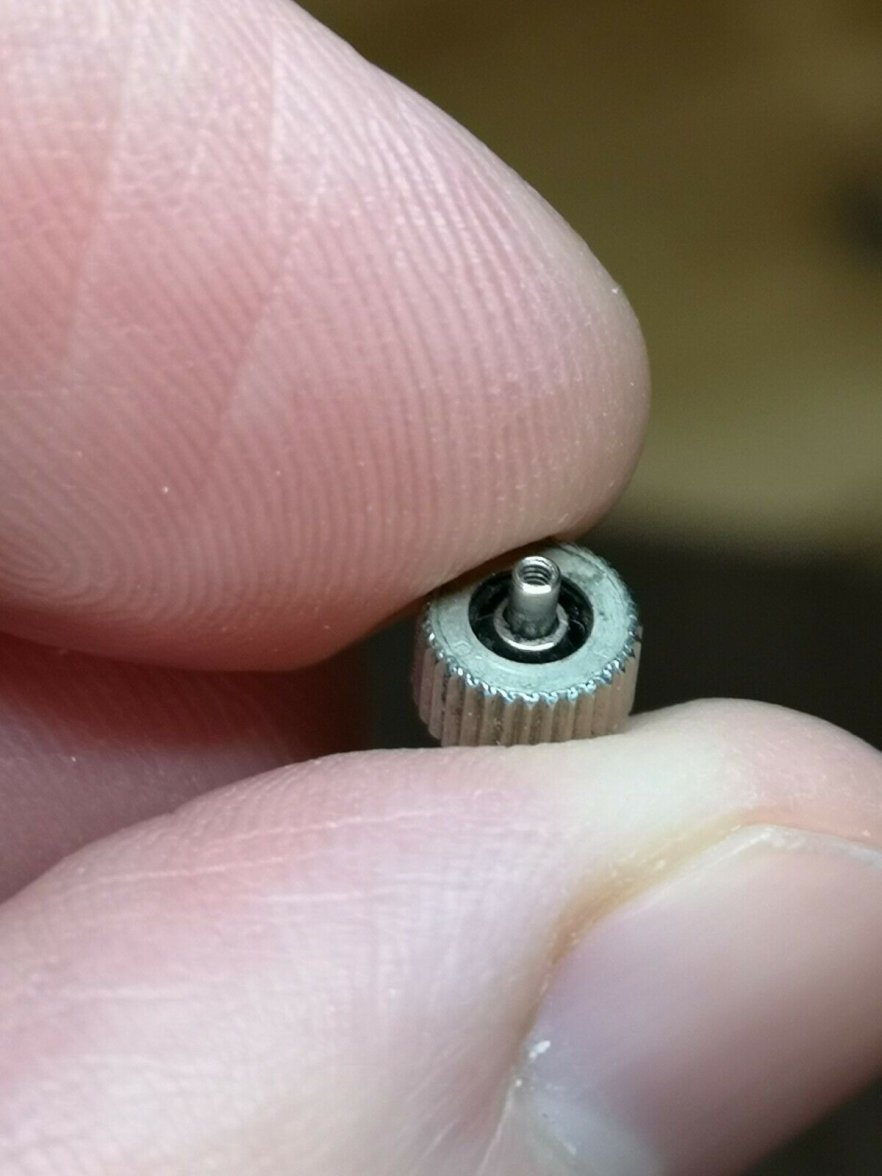

·I have an offer to buy a period-correct zenith crown I need, but it has damaged threads. The way it was described: "It's as if you had a nut and you rubbed it against something and the threads got flattened." So I assume the outermost theads are flattened and the stem can't be screwed in.

So the question: Is this easily repairable? Since the outermost threads are flattened it doens't seem as simple as just running a tap through it, for instance. But maybe it is?

I know it's hard knowing without seeing it, but that's all I got (no picture)!

So the question: Is this easily repairable? Since the outermost threads are flattened it doens't seem as simple as just running a tap through it, for instance. But maybe it is?

I know it's hard knowing without seeing it, but that's all I got (no picture)!