WestCoastTime

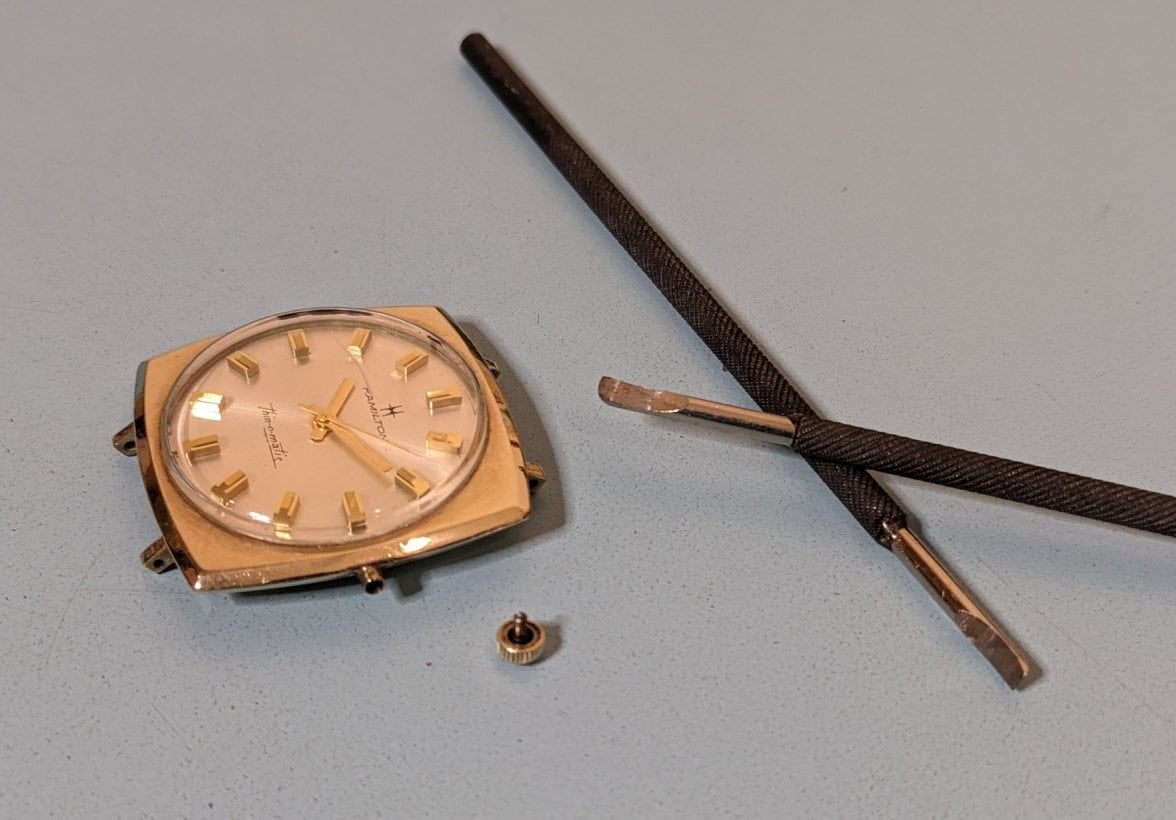

·The Hamilton Thin-o-matic

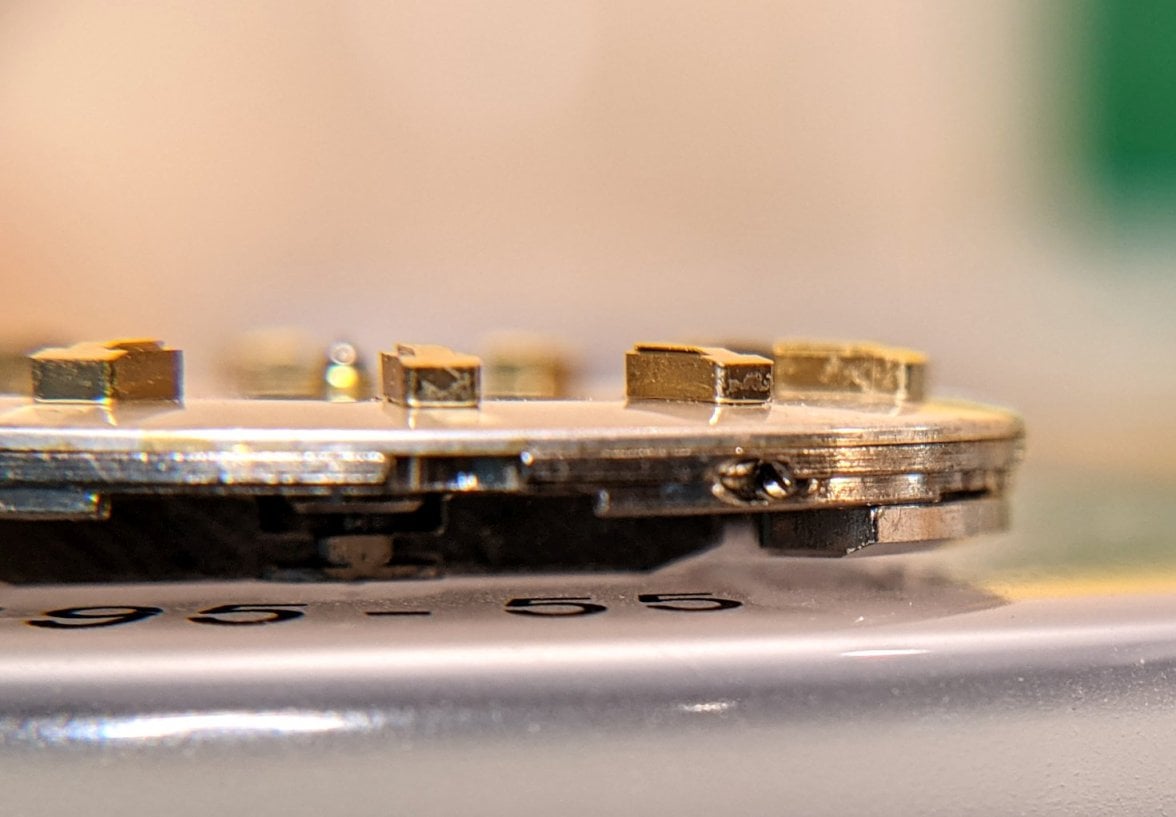

It's thin & they want you to know it...

The old familiar pocket watches were still around in abundance in the 1950's & through to the 1960's, & the watchmakers needed a hook to set the new & modern wristwatch apart from Granddad's old pocket watch.

Enter the small & thin wristwatch of the modern era.

They sure did love the one-piece case / split stem back then

Turns out, the Hamilton calibre 628 is impressively thin, even by modern comparison; 3.25mm and an auto wind movement.

But, they then choose to implement an hour, minute, seconds hand stack and dial furniture that are nearly as thick as the movement itself. So kind of defeats the purpose.

Modern ultra-thin watchmakers like Piaget or Bvlgari would make every possible effort to flatten out the hand stack & the dial to get the whole watch as thin as possible. Still impressive watchmaking if you like Hamilton, as I do.

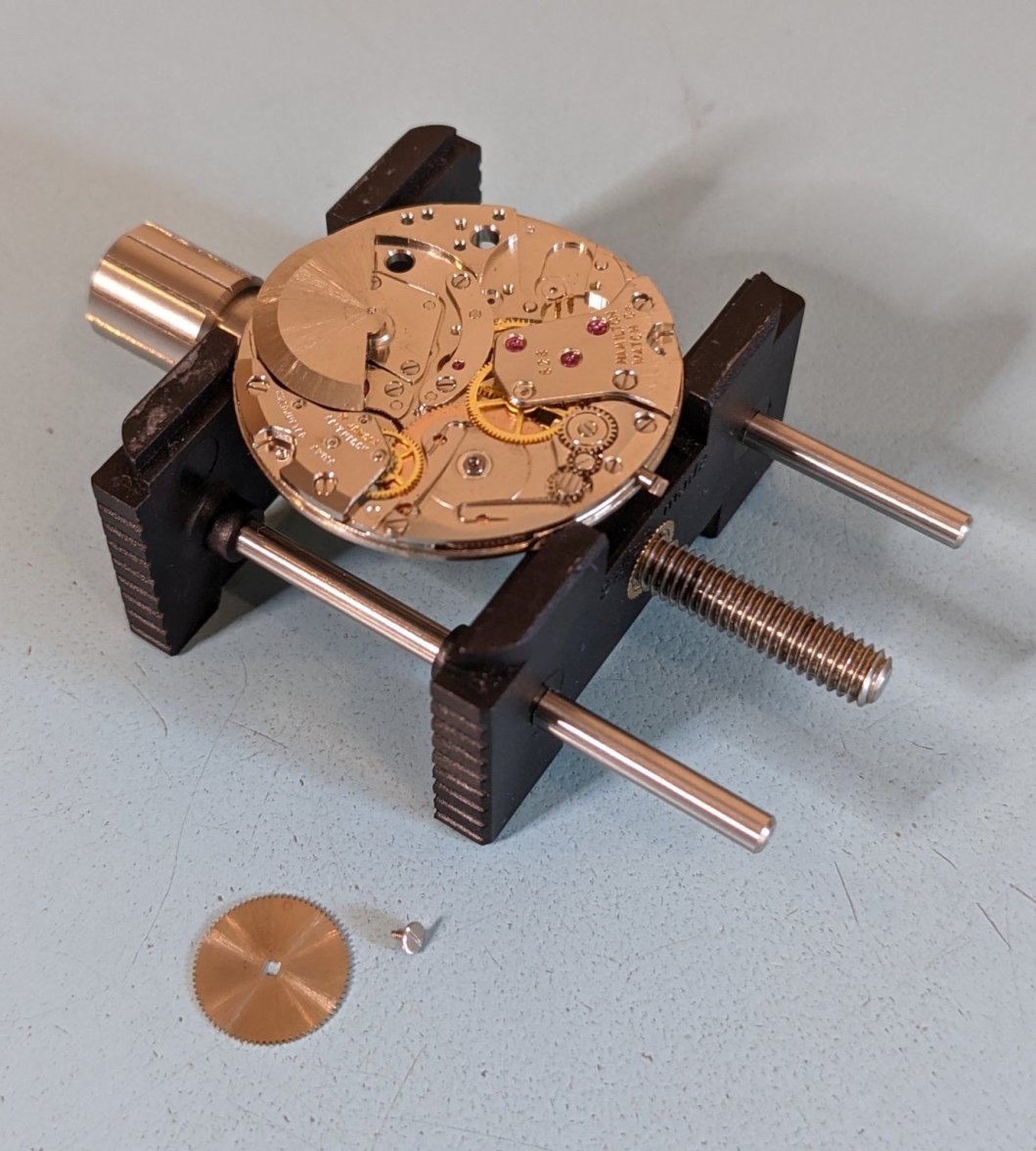

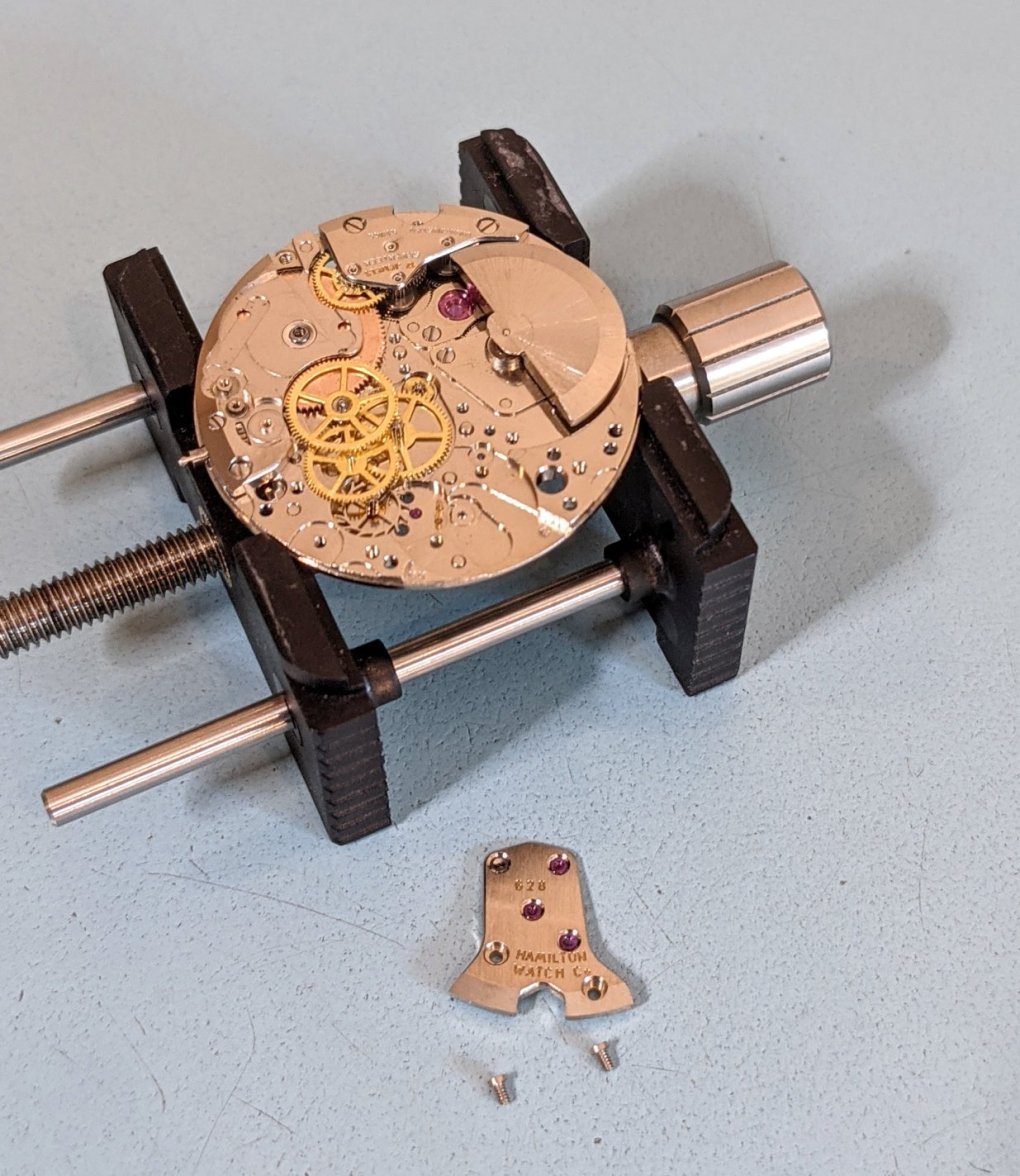

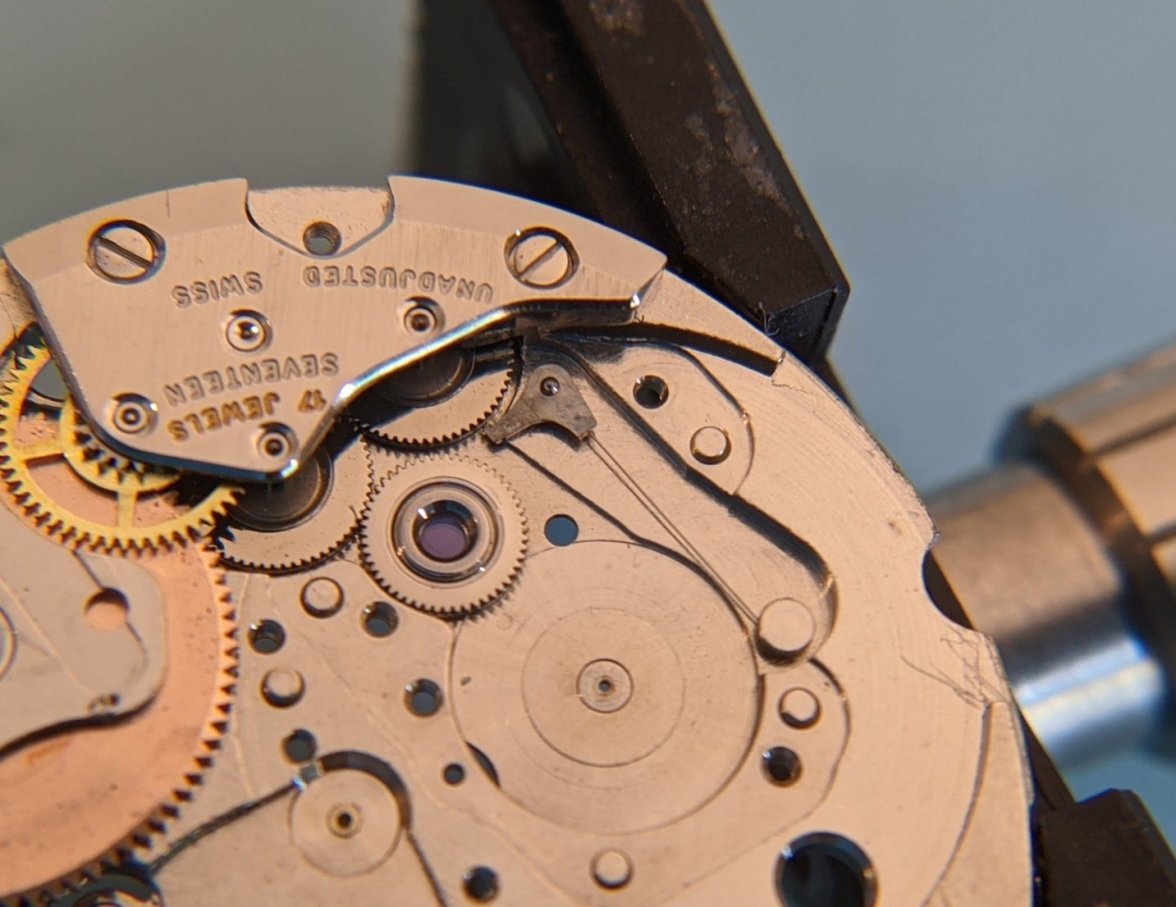

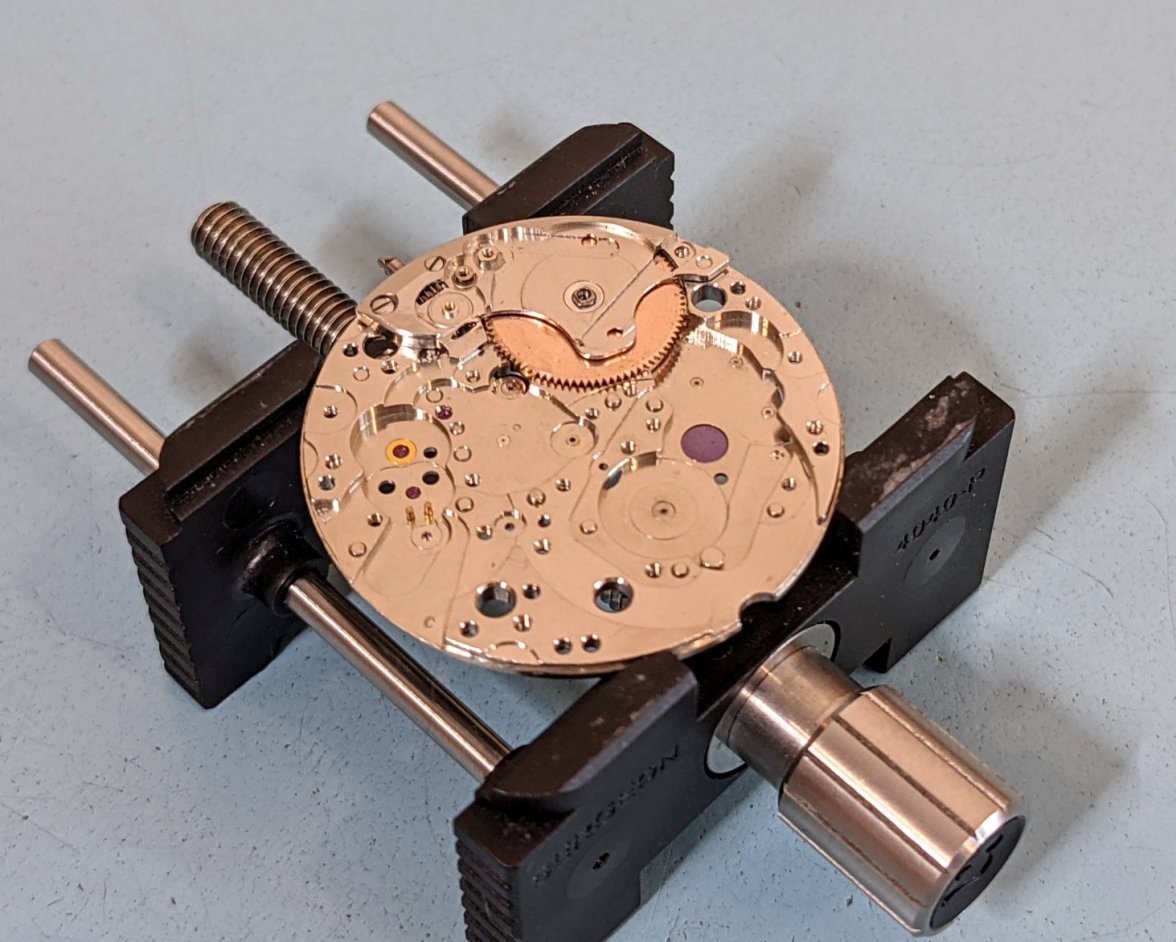

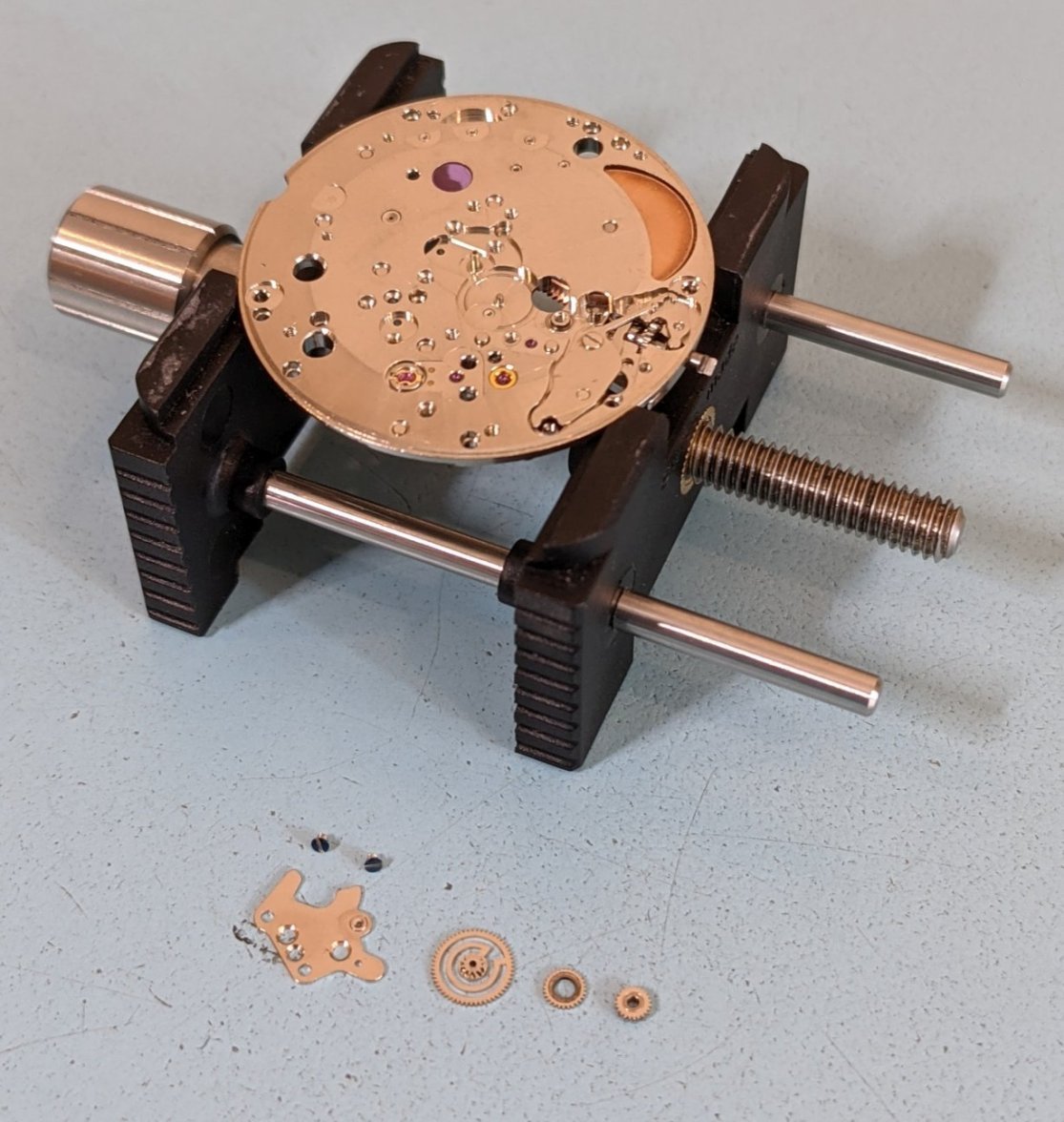

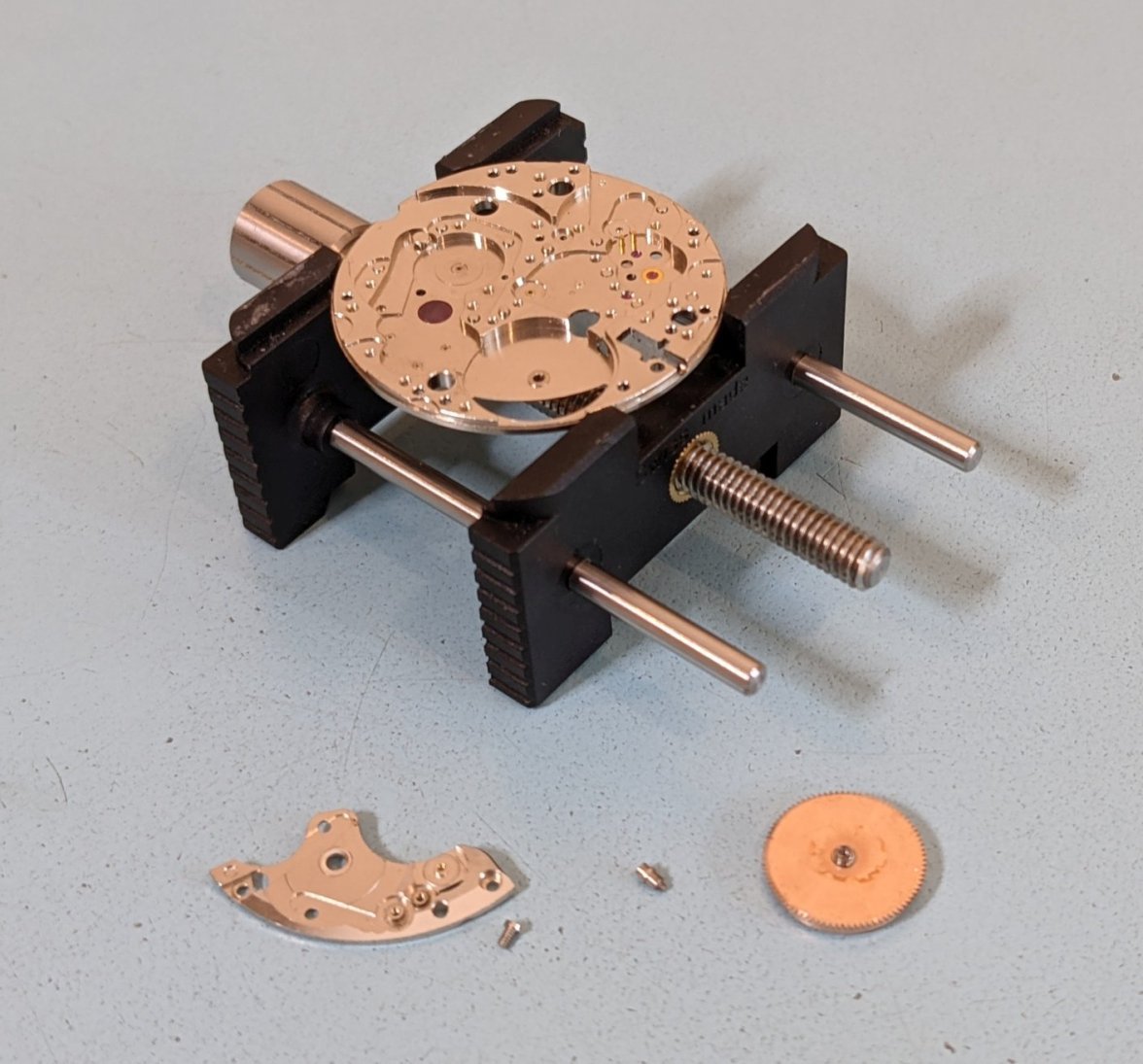

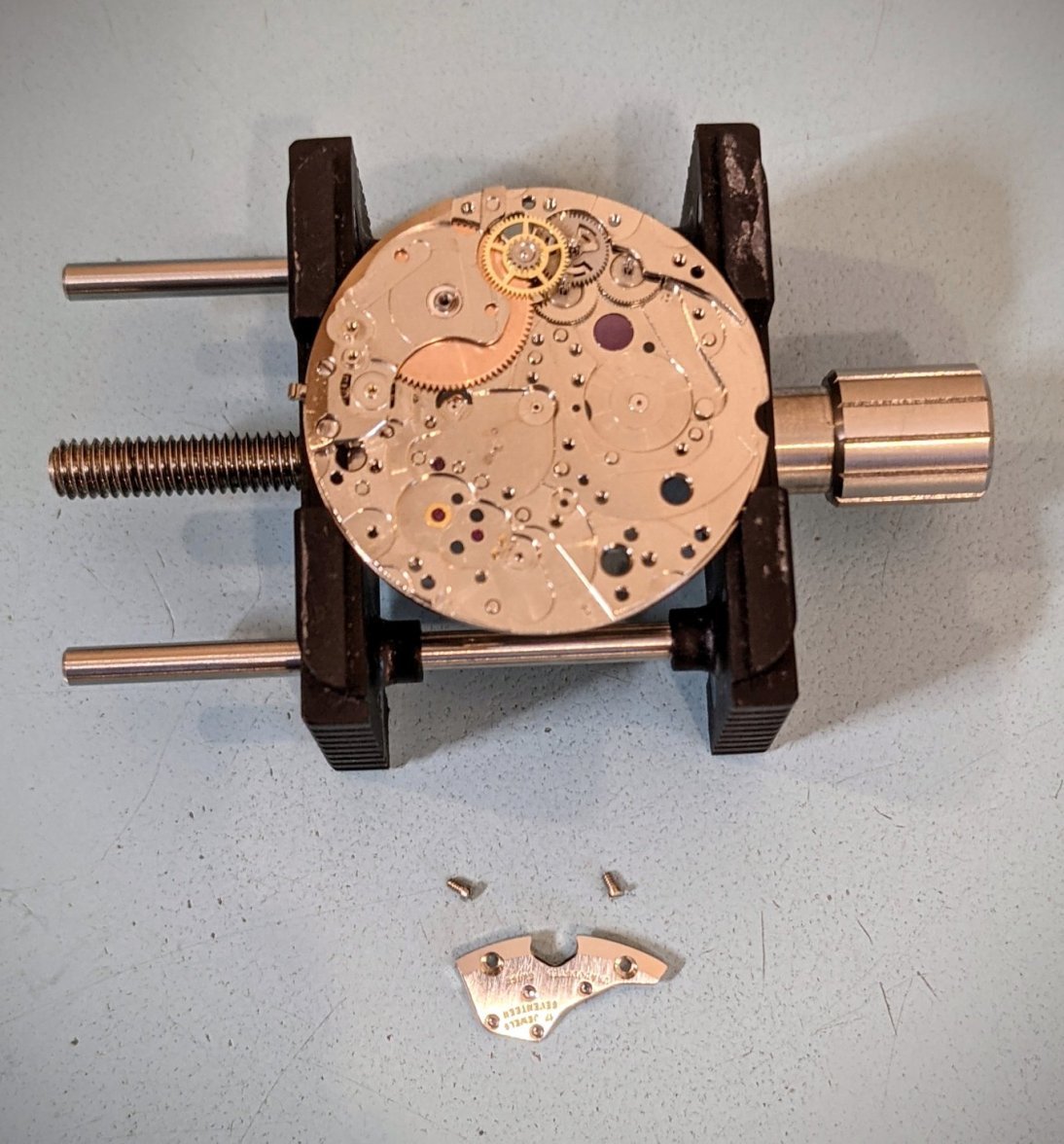

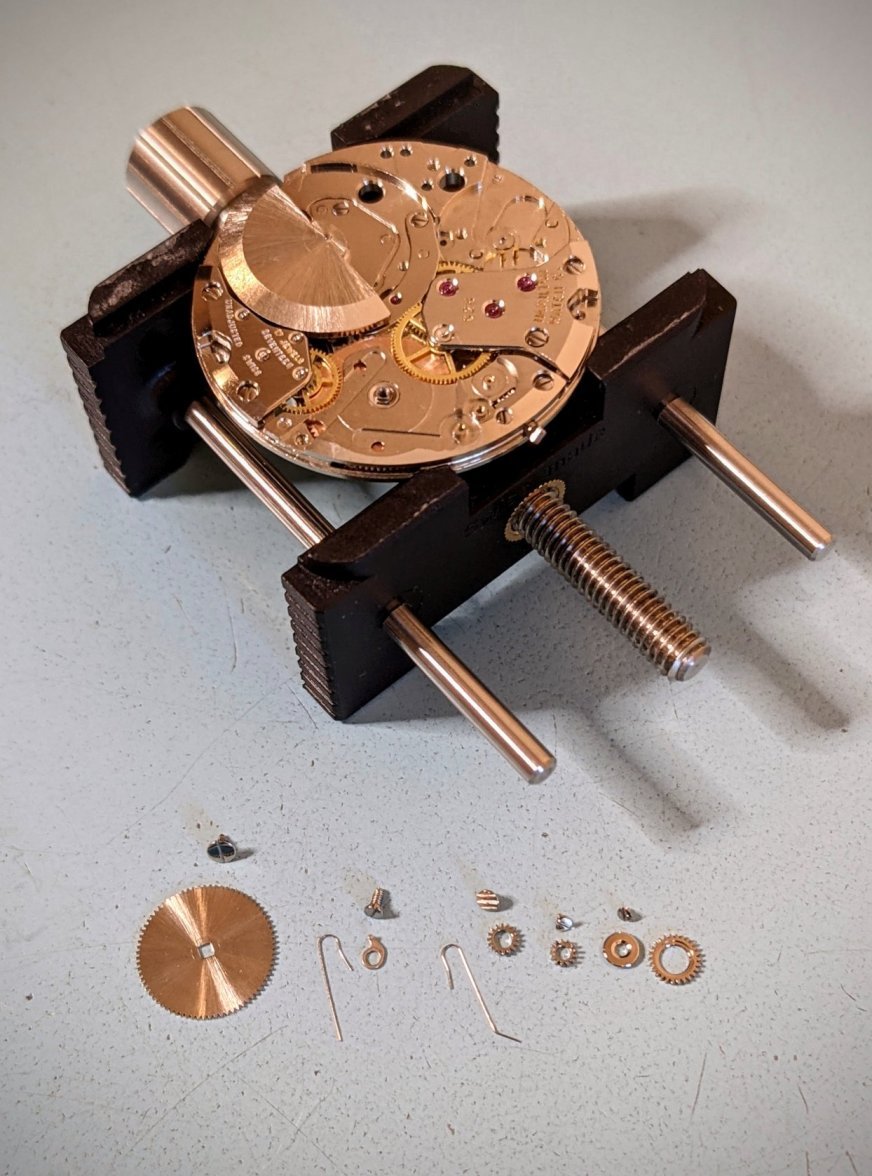

Watchmaker side of the movement

Can see how the auto wind rotor is sunk down into the plane of the movement, instead of sitting on top as a separate module. It's enough of a challenge to get any movement design implemented & working, & for a micro-rotor movement like the cal 628 the watchmakers now need to give up half of the mainplate real estate, & then also rearrange the timekeeping mechanism & everything else around the integrated auto wind mechanism.

Breaking down for cleaning

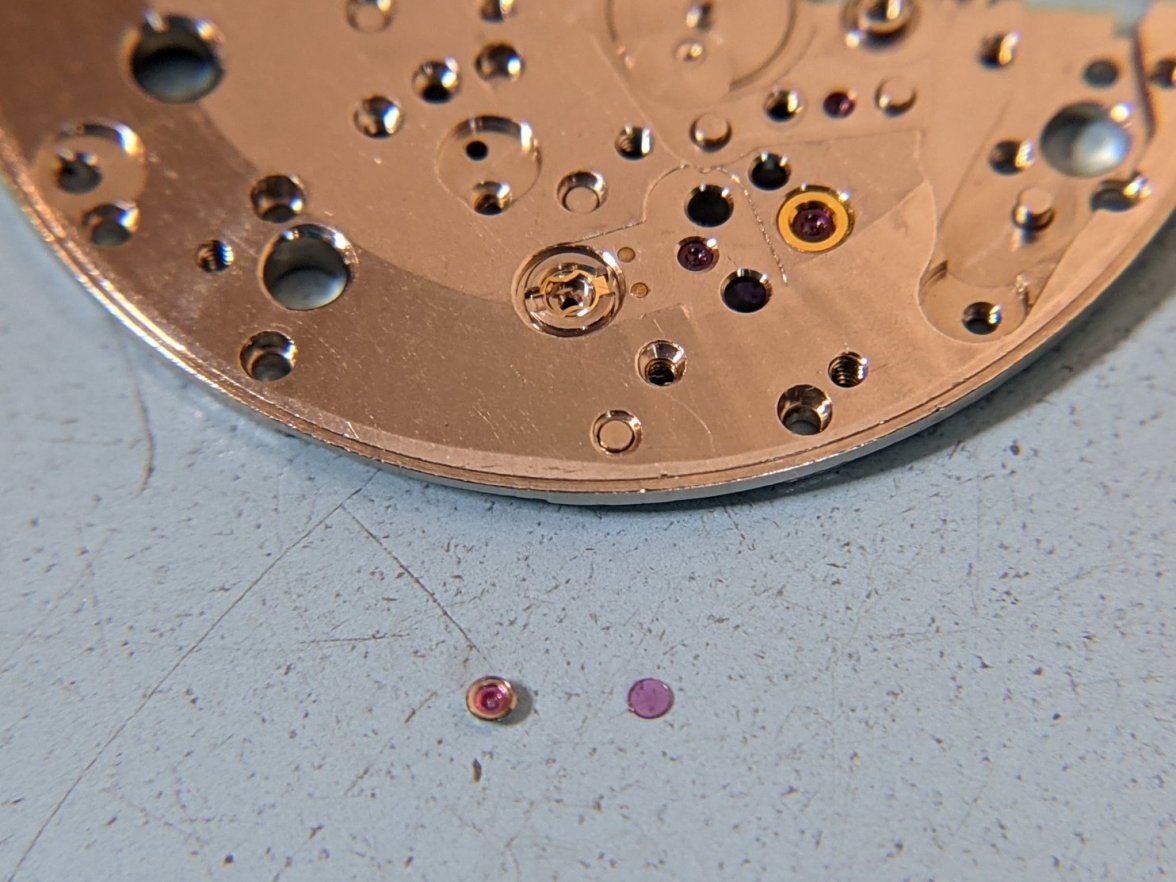

Interesting to see the heat blued screws for the pallet bridge. Not sure what (if anything) made these screws deserving of special treatment.

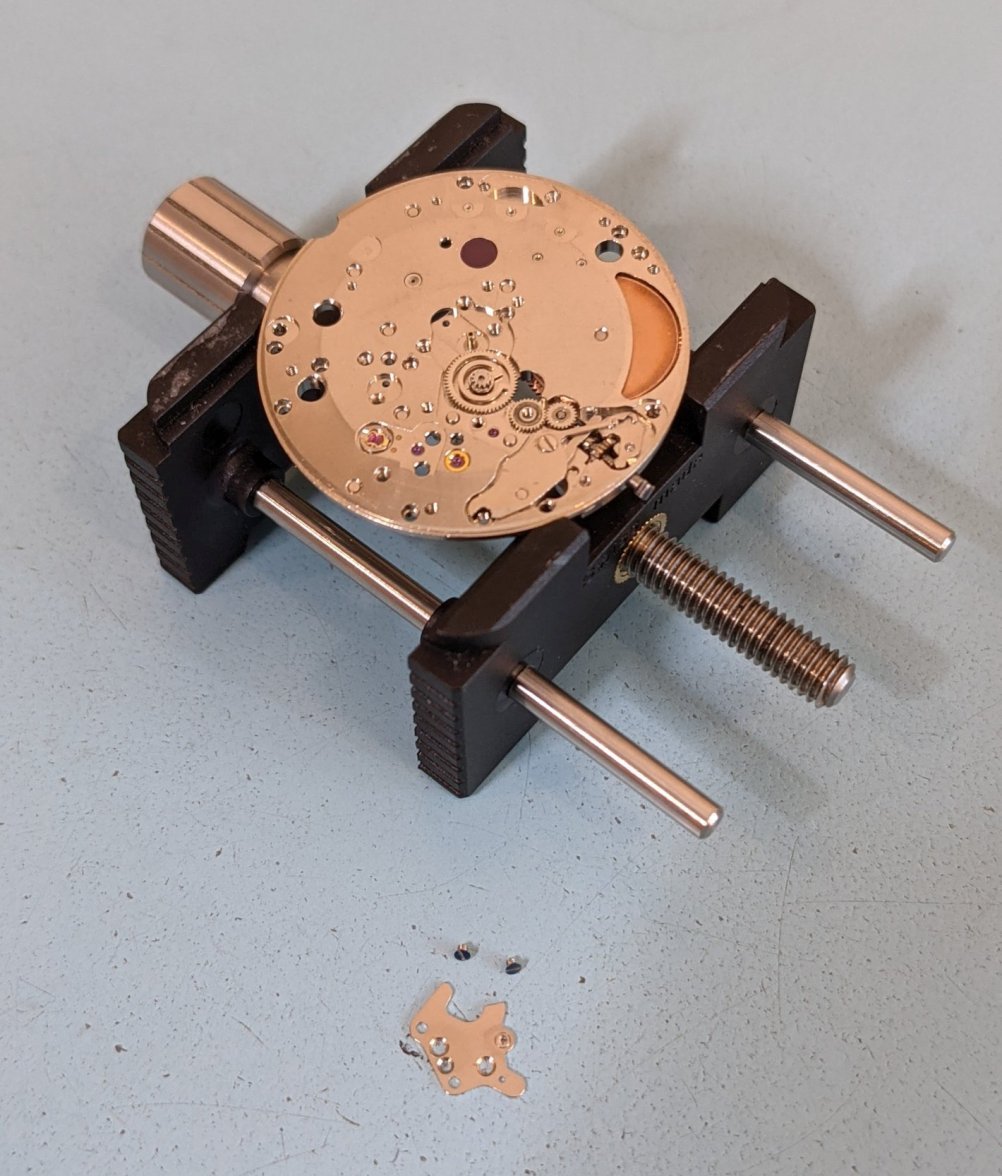

Part of the design that enables the overall thinness is clever packaging, which leads to lots of components overlapping other components. Have to do a little bit of alternating back & forth among different component groups to unpack the movement on the way down to the mainplate.

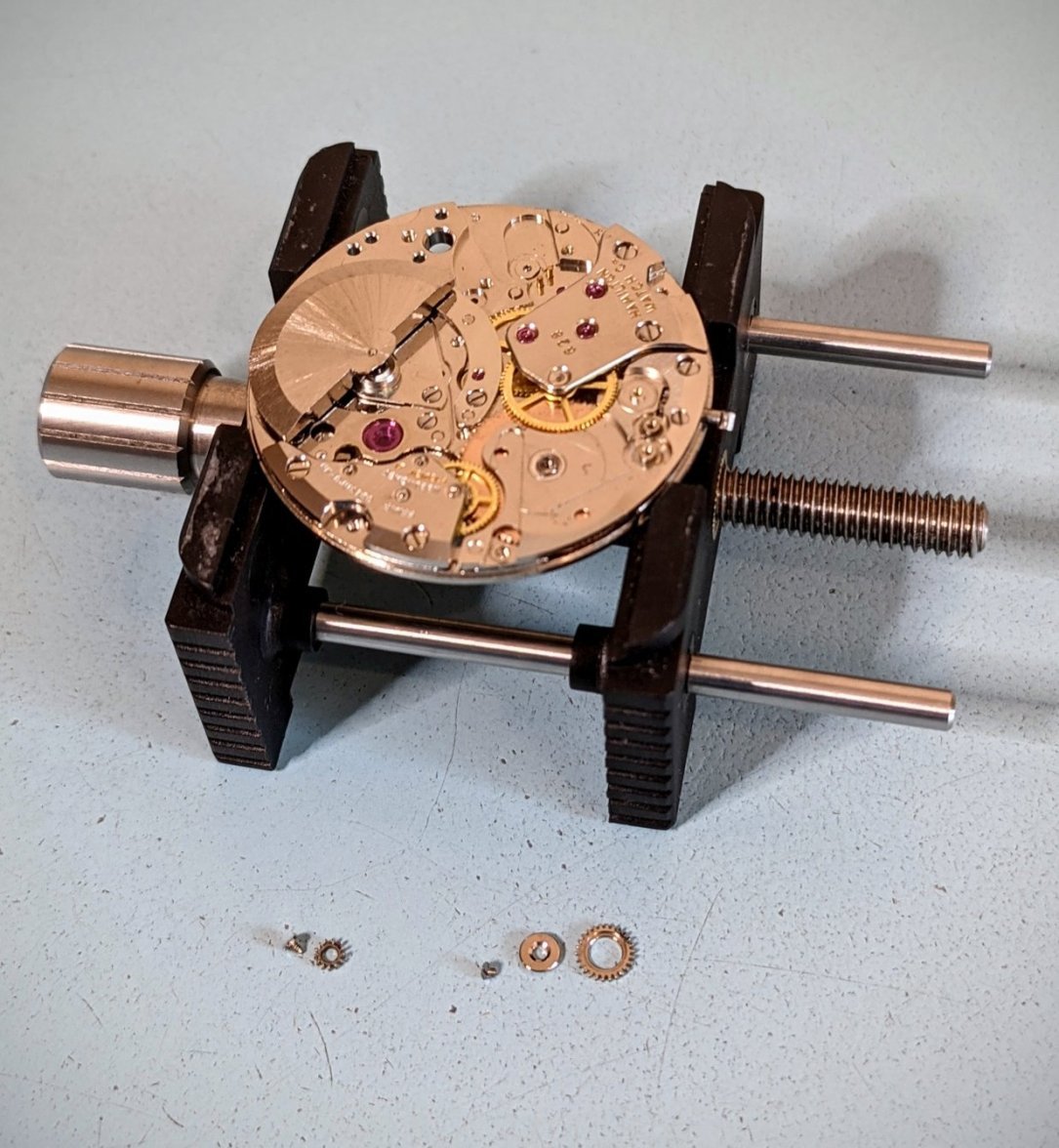

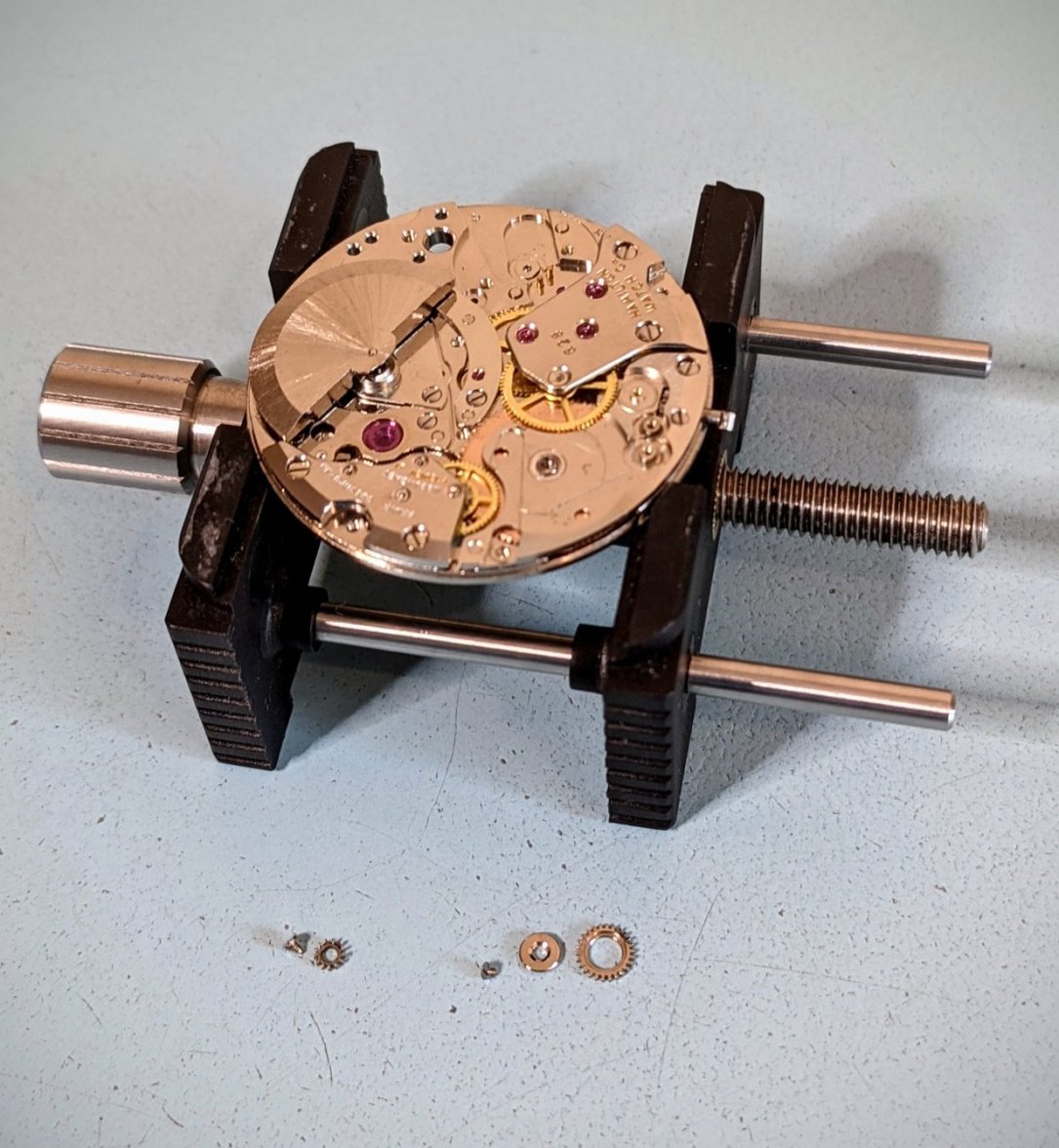

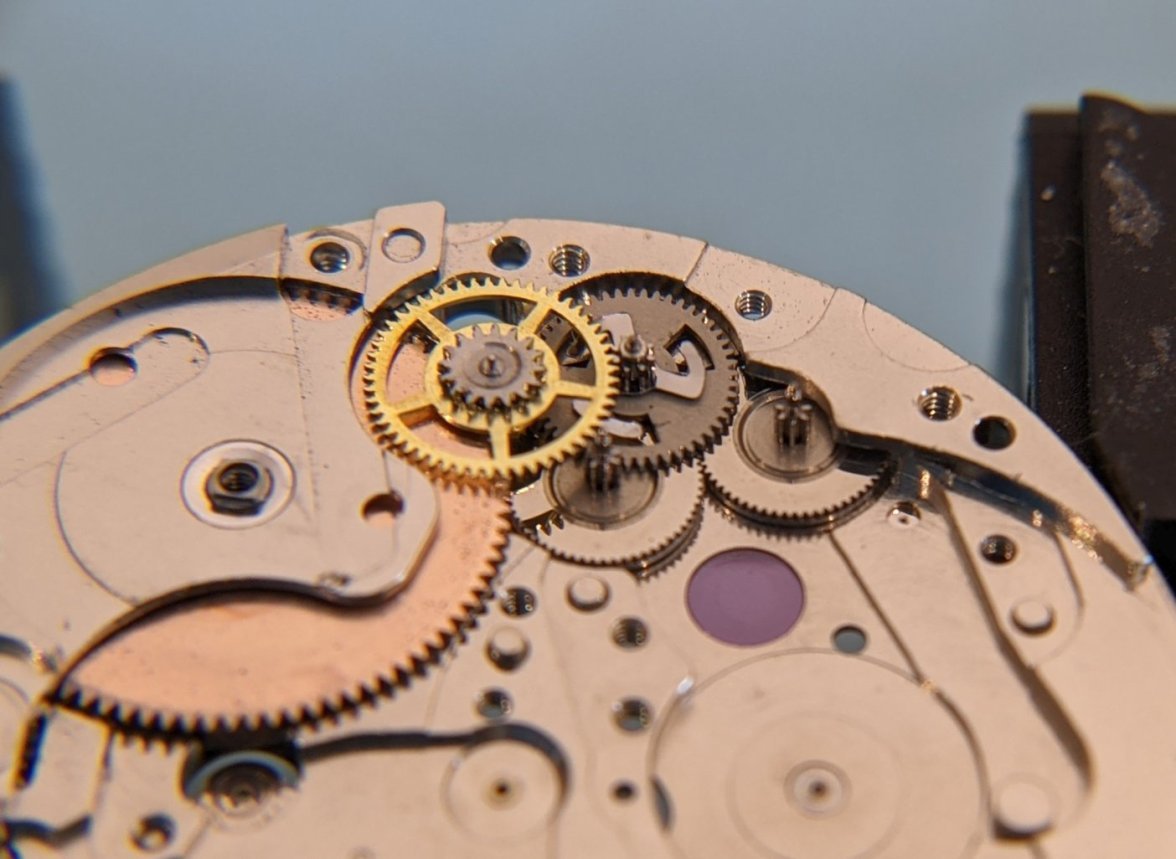

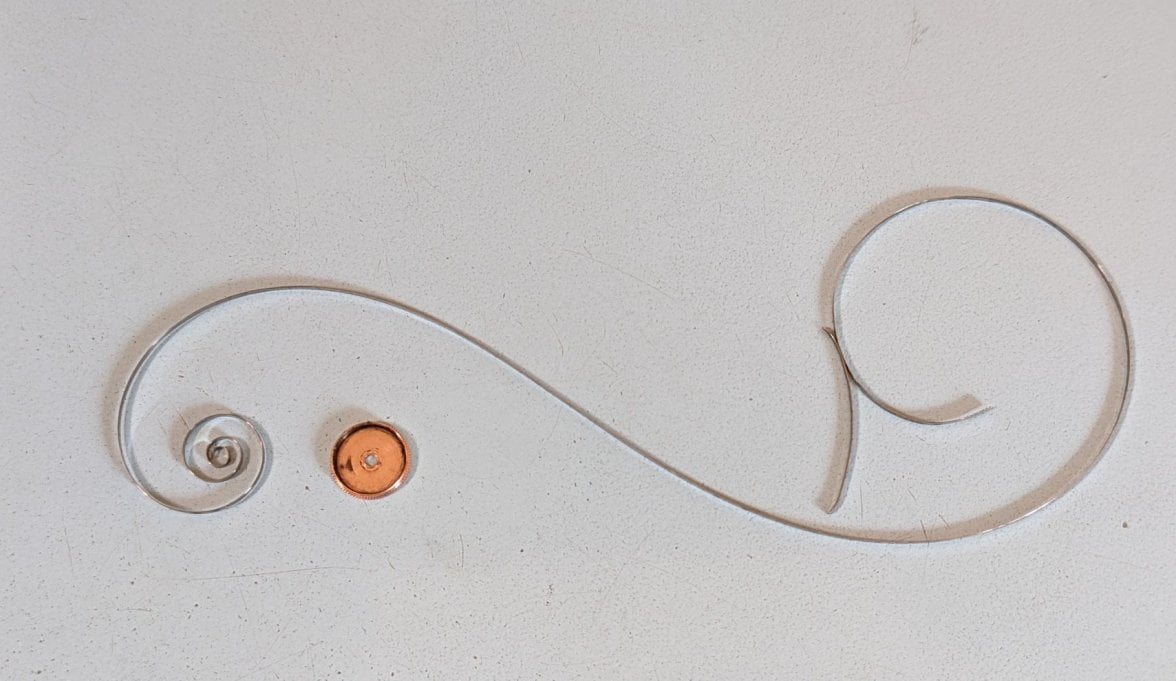

Ratchet Wheel

The spring on the right disengages the intermediate crown wheel from the ratchet wheel unless the watch is being manually wound via the stem. During manual winding the intermediate crown wheel gets pushed over into position to mesh with the ratchet wheel. Serves to decouple the manual wind action & the auto wind action.

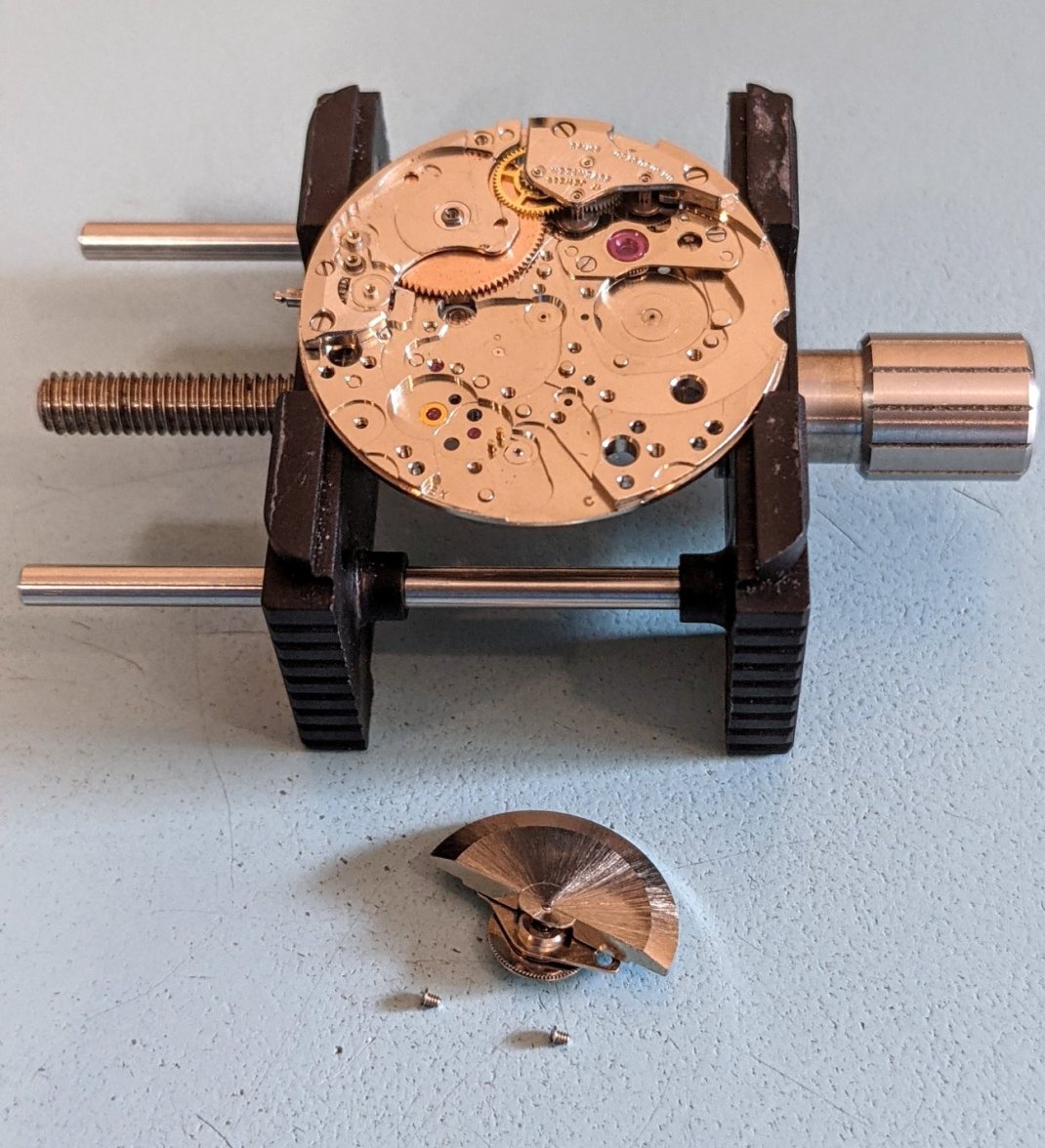

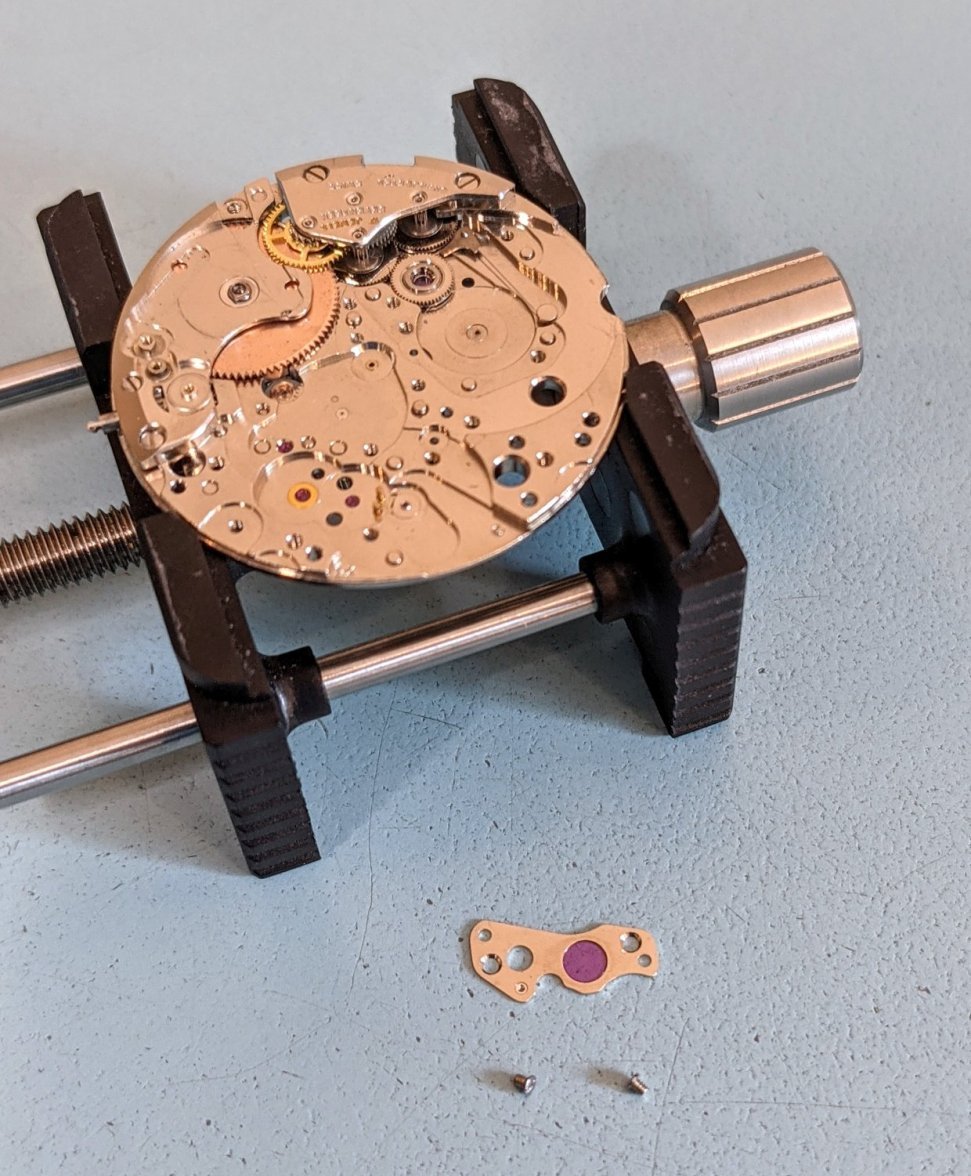

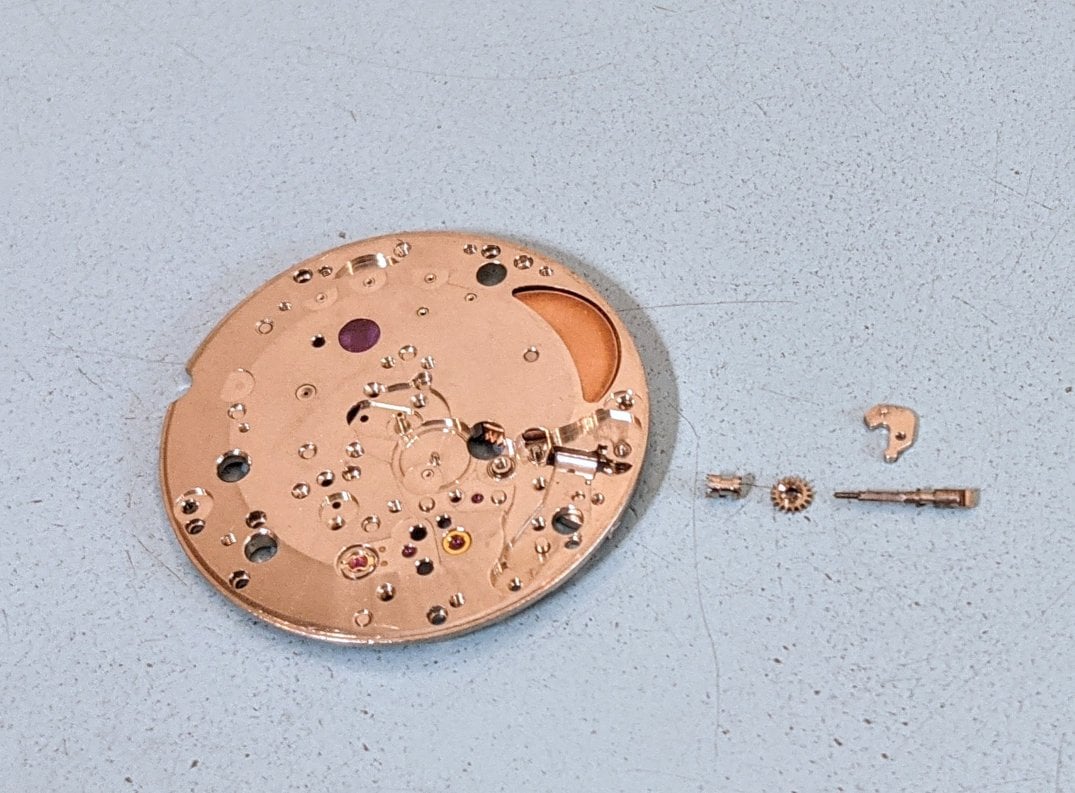

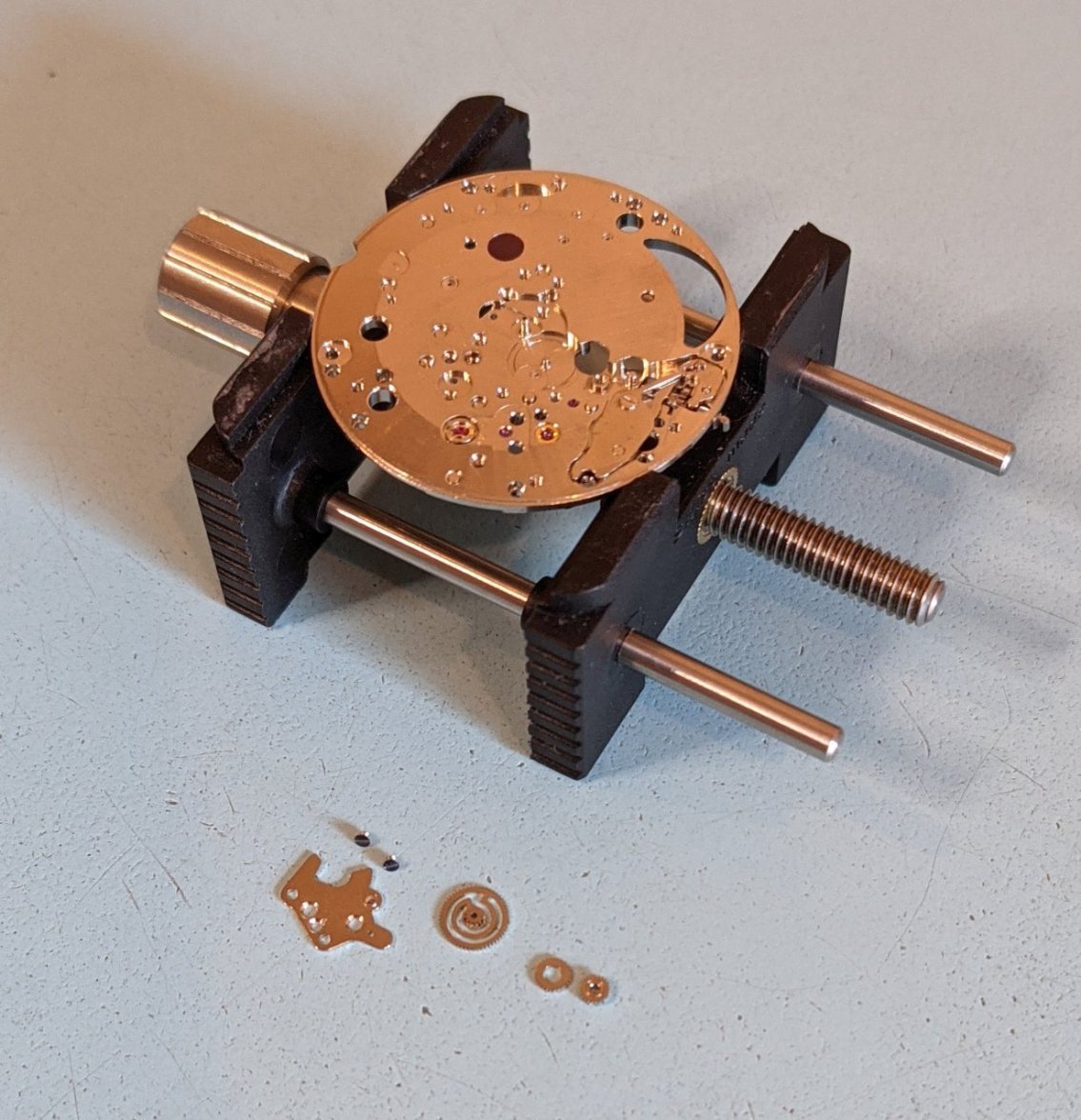

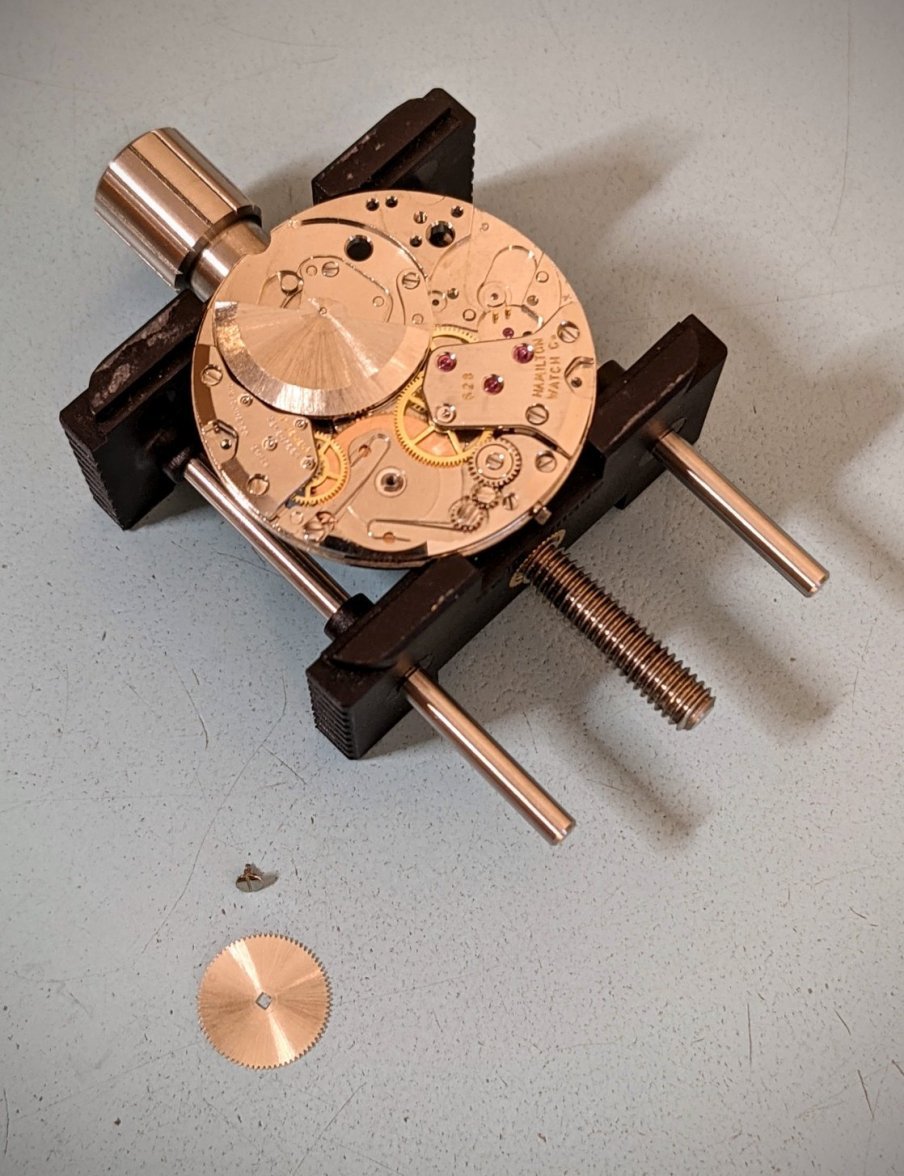

The going train

On to the auto wind mechanism...

(don't know how to delete this double photo...)

It's thin & they want you to know it...

The old familiar pocket watches were still around in abundance in the 1950's & through to the 1960's, & the watchmakers needed a hook to set the new & modern wristwatch apart from Granddad's old pocket watch.

Enter the small & thin wristwatch of the modern era.

They sure did love the one-piece case / split stem back then

Turns out, the Hamilton calibre 628 is impressively thin, even by modern comparison; 3.25mm and an auto wind movement.

But, they then choose to implement an hour, minute, seconds hand stack and dial furniture that are nearly as thick as the movement itself. So kind of defeats the purpose.

Modern ultra-thin watchmakers like Piaget or Bvlgari would make every possible effort to flatten out the hand stack & the dial to get the whole watch as thin as possible. Still impressive watchmaking if you like Hamilton, as I do.

Watchmaker side of the movement

Can see how the auto wind rotor is sunk down into the plane of the movement, instead of sitting on top as a separate module. It's enough of a challenge to get any movement design implemented & working, & for a micro-rotor movement like the cal 628 the watchmakers now need to give up half of the mainplate real estate, & then also rearrange the timekeeping mechanism & everything else around the integrated auto wind mechanism.

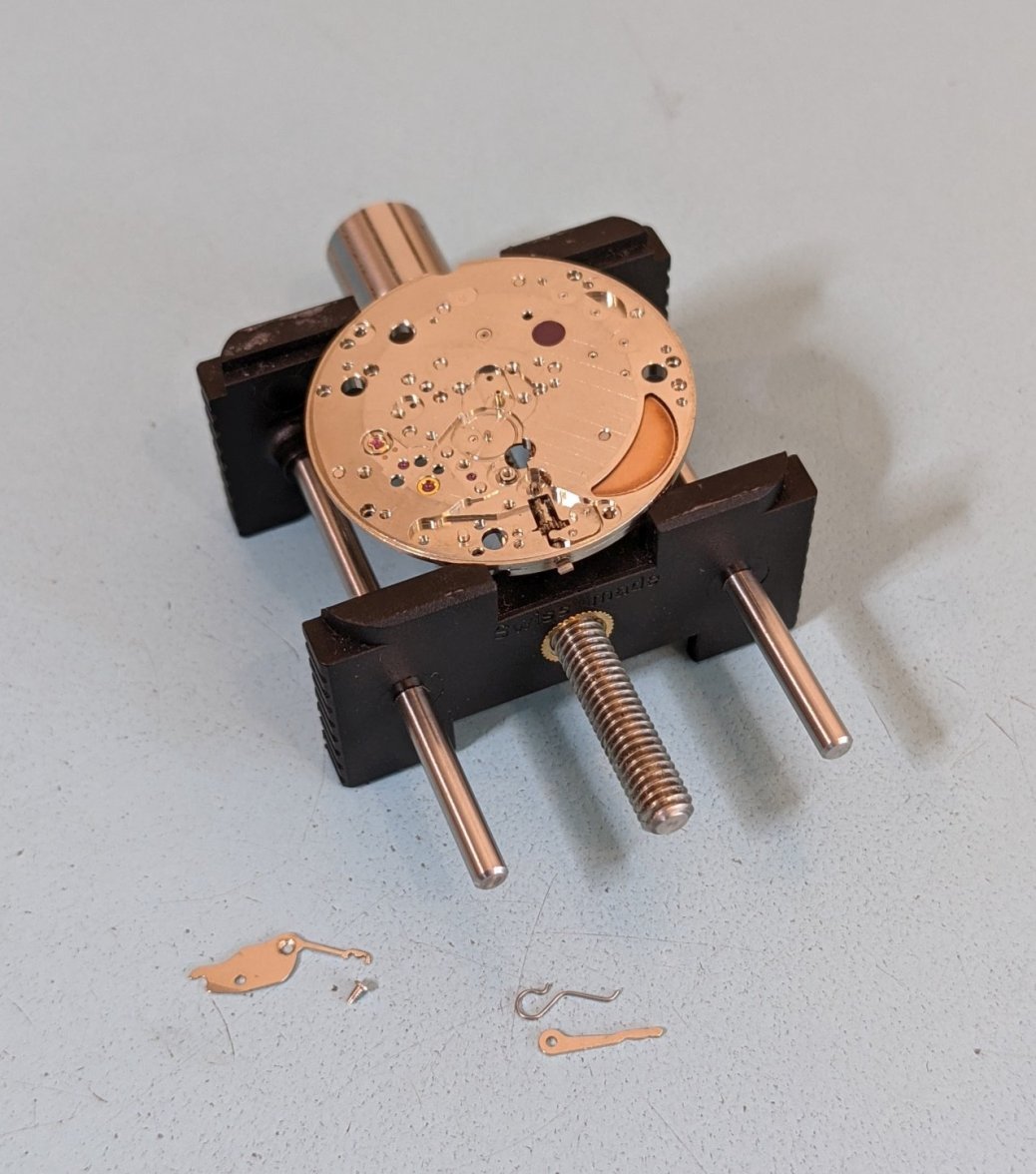

Breaking down for cleaning

Interesting to see the heat blued screws for the pallet bridge. Not sure what (if anything) made these screws deserving of special treatment.

Part of the design that enables the overall thinness is clever packaging, which leads to lots of components overlapping other components. Have to do a little bit of alternating back & forth among different component groups to unpack the movement on the way down to the mainplate.

Ratchet Wheel

The spring on the right disengages the intermediate crown wheel from the ratchet wheel unless the watch is being manually wound via the stem. During manual winding the intermediate crown wheel gets pushed over into position to mesh with the ratchet wheel. Serves to decouple the manual wind action & the auto wind action.

The going train

On to the auto wind mechanism...

(don't know how to delete this double photo...)

Edited: