Dan S

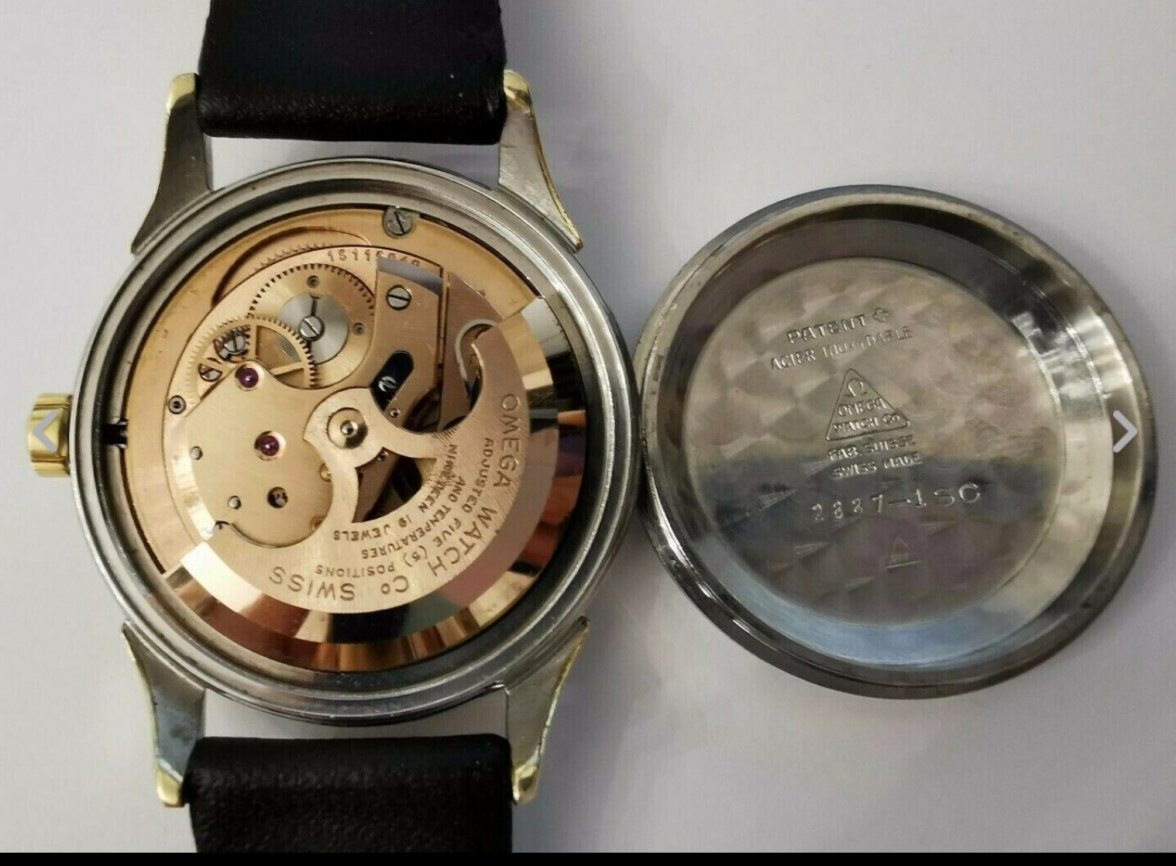

·I agree. I have some really nice watches with signs of past rotor rub inside the back, but the rotors must have been subsequently replaced as there is no further problem. Rotors were often replaced during services, so it would be massively overreacting to reject a watch just on account of rotor rub signs.

I agree that rotors are sometimes replaced, but the underlying problem that causes rotor rub can generally be addressed by replacing the bearing/bushing I believe. So the rotor itself can be preserved.