Diabolik

·I had no responses to my request so the only thing left was to have a go at making one ...

first task is to take measurements of existing hand. We are working in the submillimeter range so measurements need to be pretty precise (+/- 0.05mm) ..

The best way to hold very small parts when machining them is to use Rodico 6033-1. Put a small amount on milling table, ensure it slightly sinks into putty and you are ready. I am using an old hand of approximately the same width but much longer and aim to cut it down to size when done.

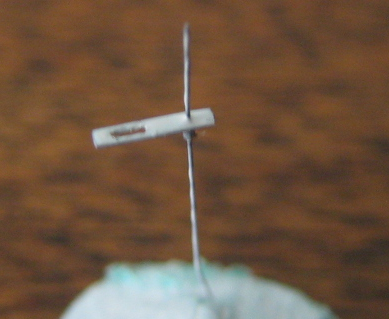

First part is to create the slit for the lume. I an using an 0.3mm milling tool (reshaped drill bit) to make a channel, then drill the start and end and mill away the solid material between holes.

all I need to do now, is polish it and remove burrs. cut it to size (red box) drill a hole for tube which will be soldered on and paint/lume it.

Sounds straight forward but it has taken me half a day to get to this point !

first task is to take measurements of existing hand. We are working in the submillimeter range so measurements need to be pretty precise (+/- 0.05mm) ..

The best way to hold very small parts when machining them is to use Rodico 6033-1. Put a small amount on milling table, ensure it slightly sinks into putty and you are ready. I am using an old hand of approximately the same width but much longer and aim to cut it down to size when done.

First part is to create the slit for the lume. I an using an 0.3mm milling tool (reshaped drill bit) to make a channel, then drill the start and end and mill away the solid material between holes.

all I need to do now, is polish it and remove burrs. cut it to size (red box) drill a hole for tube which will be soldered on and paint/lume it.

Sounds straight forward but it has taken me half a day to get to this point !