Diabolik

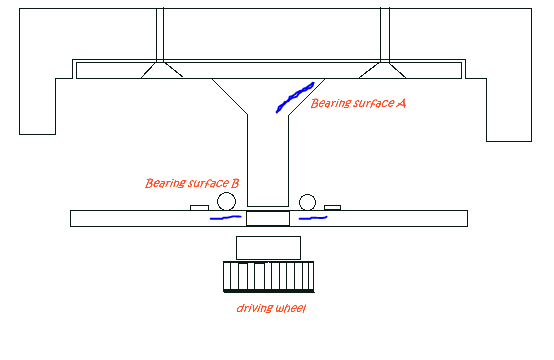

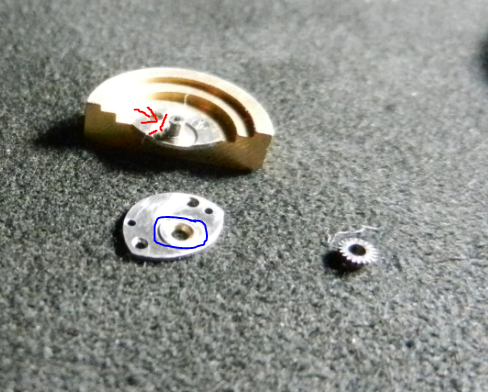

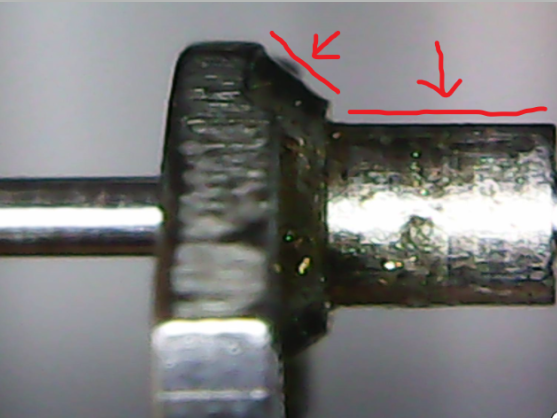

·Following a couple of attempts, I have designed a fix for the newer microtor bearings that are so prone to failure. The new bearing is made of brass and is tapered so glides over the tapered base of the microrotor pinion. Everything fits snugly with hardly any play and when tested, rotated with very very well ...

Thoughts ?

Thoughts ?