impalla62ss

·This message will not potentially self district in five minutes.

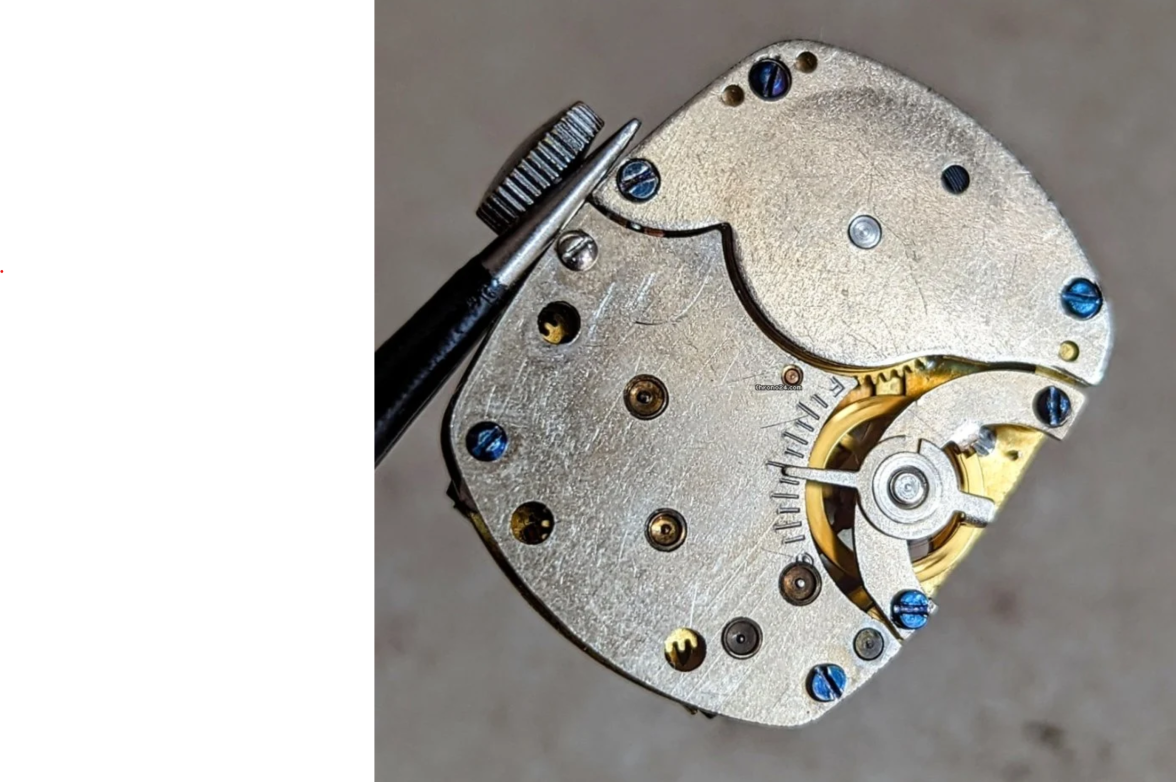

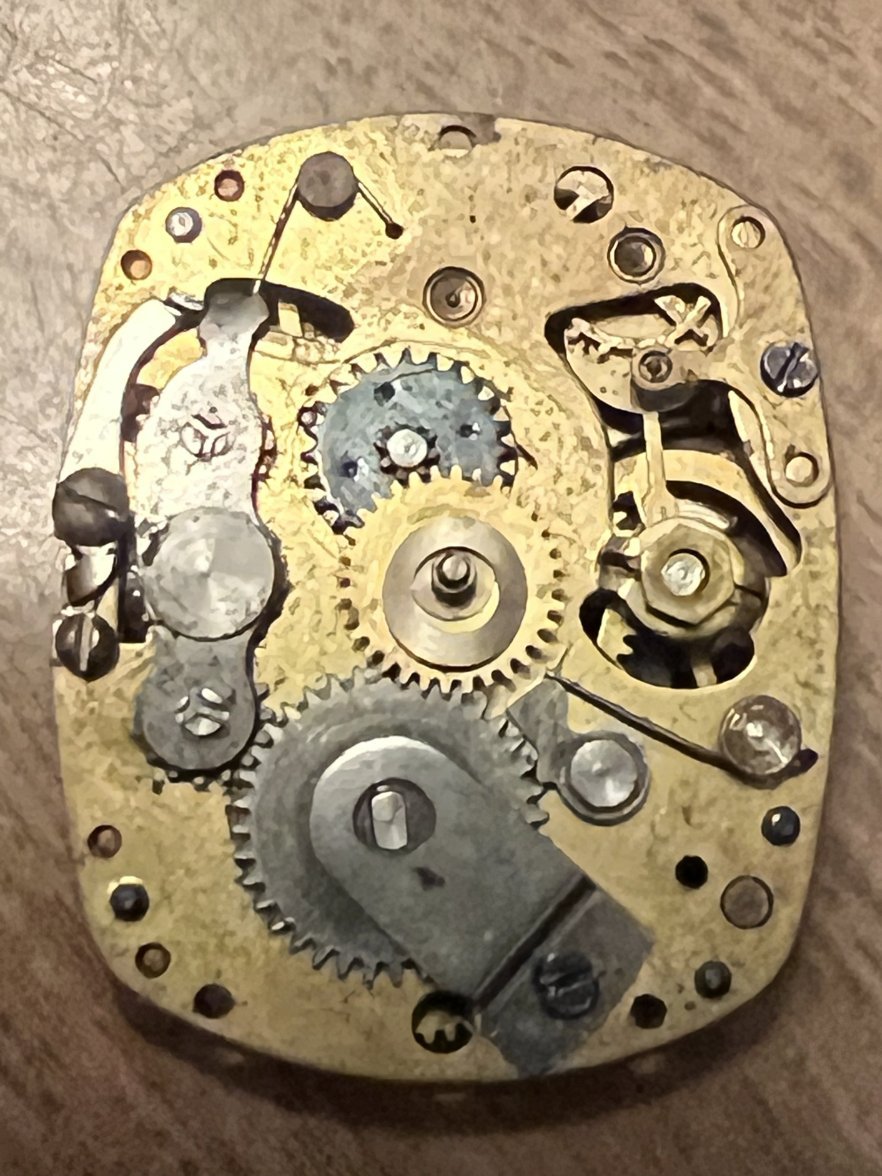

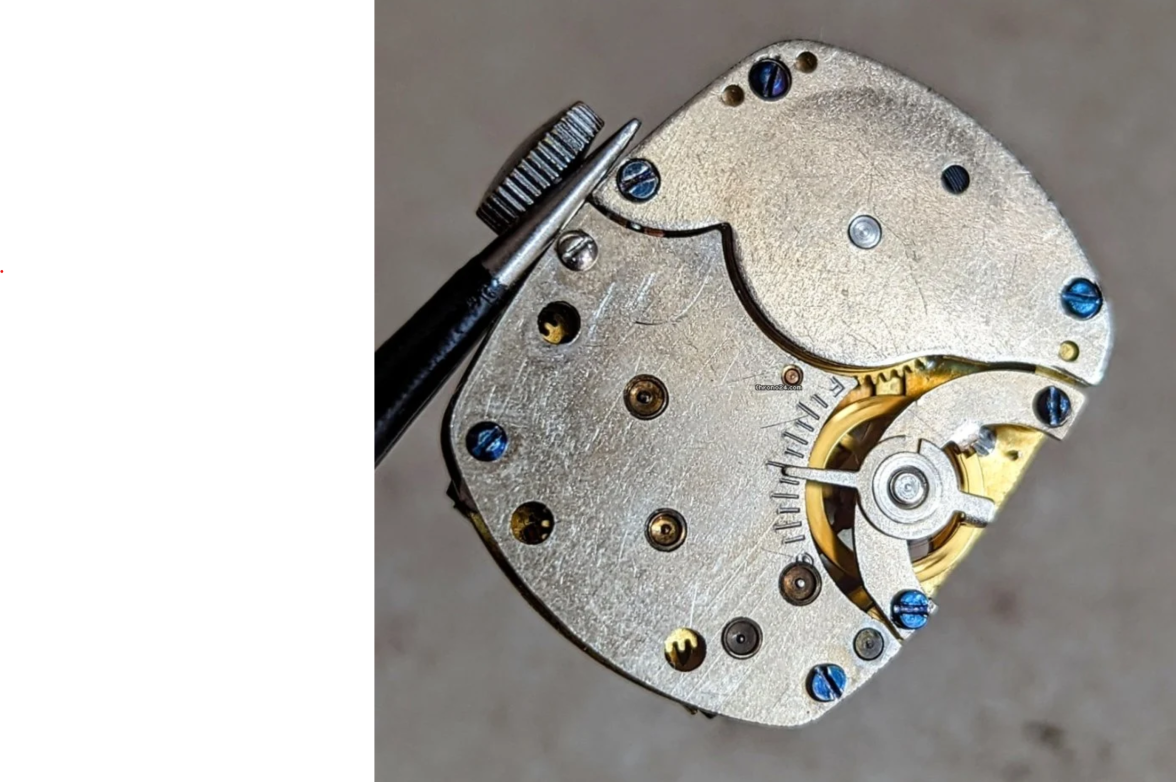

I have my dad's mickey mouse watch that he took a wrench to the crown on. As a kid he did not want to be seen wearing it. I have found two parts watches. His is the one with the red strap and the Ref. number on the back. I was wondering if I could pay you to open them up and see if you can salvage one movement out of the three heads? Not sure if anyone would be willing to take a look. No worries if you are not interested as pin lever escapements are difficult to work on.

It is a manual wind watch powered by a standard pin lever escapement movement; U.S.A. made. 1948 Ingersoll / US Time Case Back. https://omegaforums.net/threads/got-mice-mickey-mouse-watches.138353/page-2#post-2188355

Thanks in advance for your consideration.

I have my dad's mickey mouse watch that he took a wrench to the crown on. As a kid he did not want to be seen wearing it. I have found two parts watches. His is the one with the red strap and the Ref. number on the back. I was wondering if I could pay you to open them up and see if you can salvage one movement out of the three heads? Not sure if anyone would be willing to take a look. No worries if you are not interested as pin lever escapements are difficult to work on.

It is a manual wind watch powered by a standard pin lever escapement movement; U.S.A. made. 1948 Ingersoll / US Time Case Back. https://omegaforums.net/threads/got-mice-mickey-mouse-watches.138353/page-2#post-2188355

Thanks in advance for your consideration.