How tight is too tight when screwing down the crown on a Diver 300M? Can you over-tighten it?

Archer

··Omega Qualified WatchmakerOr they just see the value of redundancy. Two is one and one is none.

Yes, this is expected argument. But then why only on the crown? Why doesn't Rolex have two O-rings for the case back if it's purely for redundancy? The seal that compresses on the end of the case tube only comes into play when the crown is fully screwed down - the seal in the case back only comes into play when the case back is fully screwed down.

From an engineering perspective, it makes no sense to do it in one place, and not another if redundancy is the only reason.

Aroxx

·Yes, this is expected argument. But then why only on the crown? Why doesn't Rolex have two O-rings for the case back if it's purely for redundancy? The seal that compresses on the end of the case tube only comes into play when the crown is fully screwed down - the seal in the case back only comes into play when the case back is fully screwed down.

From an engineering perspective, it makes no sense to do it in one place, and not another if redundancy is the only reason.

hen

·Yes, this is expected argument. But then why only on the crown? Why doesn't Rolex have two O-rings for the case back if it's purely for redundancy? The seal that compresses on the end of the case tube only comes into play when the crown is fully screwed down - the seal in the case back only comes into play when the case back is fully screwed down.

From an engineering perspective, it makes no sense to do it in one place, and not another if redundancy is the only reason.

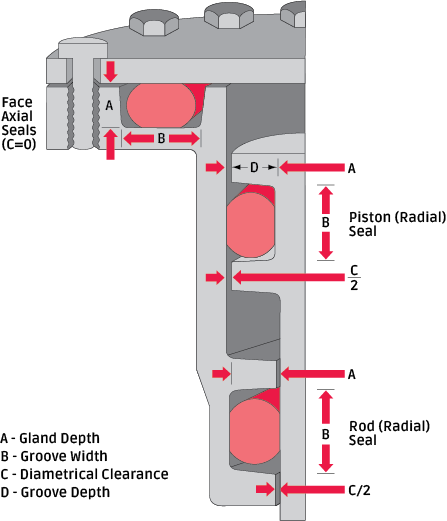

Found a pic of what is meant by axial and radial seals.

But I guess Omega knows what they are doing. Learned something today as well.

I guess the reason for Rolex not using two seals in the case back is because of the better seal of the axial seal and because the case back isn`t regularly operated by the owner thus experiencing less wear.

Archer

··Omega Qualified WatchmakerThanks for the answer. This is really strange, not that I don`t believe you, but its just much easier to get a good seal with axial compression than radial compression seal.

Not when your crown threads are stripped! 😉

The radial seal is all that's needed - it is in constant contact with the case tube, and the compression is engineered into the design. There's really nothing that can cause a problem here, other than lack of maintenance.

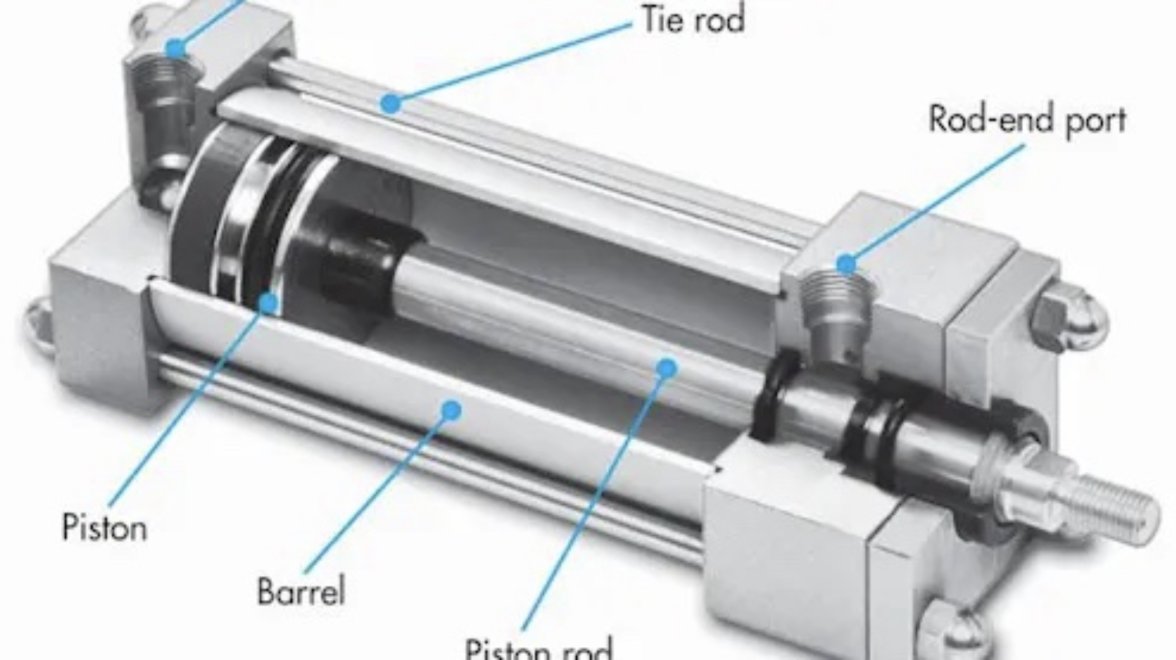

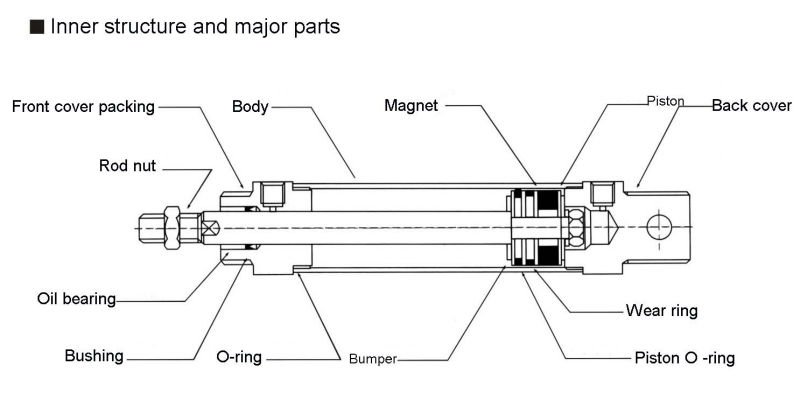

This kind of seal (piston seal) is used in so many applications that the engineering behind it isn't a mystery. Virtually every pneumatic or hydraulic cylinder on the planet uses this design, so it's not something unheard of by any means.

I guess the reason for Rolex not using two seals in the case back is because of the better seal of the axial seal and because the case back isn`t regularly operated by the owner thus experiencing less wear.

Possibly, but that wasn't really what I was challenging - I was challenging the idea that the extra seal is purely for redundancy.

gatsuk

·Screwing it until the crown is flush with the case is fine I think.

The thing is, if you screw it until you get a resistance could run the risk of stripping.

The thing is, if you screw it until you get a resistance could run the risk of stripping.

DougPhx

·A long explanation but, imho, an easy answer.

My father was one of those people who was good at everything. He died some years ago - he was an officer in the British Army through the Second World War. I’m 69 and I miss him every day. But he taught me everything.

So … don’t force it (I can hear his words). Tighten it until you can feel it’s sealed. Don’t overtighten anything. Wait until you feel some resistance and then turn it just a little more, maybe an 1/8 th of a turn, no more. It’s been designed that way.

Omegas are designed to be passed on. I have a 1967 Constellation certified chronometer with a calibre 751. I researched this calibre and apparently the engineers designed it to last 265 years. Sympathise with it and it’ll pay you back.

DougPhx

·Thanks! I'm wondering and really hoping if the 300M has this same crown system (as they say "600M" on the images assuming its a Planet Ocean), someone also wondered in the comments but it was left unanswered. It'd be good to have a 5ATM safety even with a fully open crown, but somehow I don't trust that claim from the image (as it's not from this model and not from Omega directly)

Anyways, I'll probably take it to an experienced watchmaker in town and ask them to tighten to a point where they would on other watches, just for reference and take a picture of the crown position and how tight/loose they get it

I have the same reference. Try not to increase the torque too much with your fingers as you feel resistance near the end. Just keep rolling to the stop with the same force, don’t wind too much harder.

I think this is where watch owners can get in trouble…especially if they have any OCD tendencies…over think it then over crank the crown at the end. When the crown stops so should your fingers. Be 100% confident that it is properly sealed and enjoy it!

hen

·Not when your crown threads are stripped! 😉

The radial seal is all that's needed - it is in constant contact with the case tube, and the compression is engineered into the design. There's really nothing that can cause a problem here, other than lack of maintenance.

This kind of seal (piston seal) is used in so many applications that the engineering behind it isn't a mystery. Virtually every pneumatic or hydraulic cylinder on the planet uses this design, so it's not something unheard of by any means.

Possibly, but that wasn't really what I was challenging - I was challenging the idea that the extra seal is purely for redundancy.

Pneumatic or hydraulic cylinders use Zimmerrings seals with a lip that are pressed against the shaft or axle by a spring and internal pressure. Quite different from an O-ring.

I think you are right if Omega don`t need that extra seal it must be for redundancy. Tri-lock or what they call it, sounds good in marketing though. I would have been comforted by that fact I think.

Archer

··Omega Qualified WatchmakerPneumatic or hydraulic cylinders use Zimmerrings seals with a lip that are pressed against the shaft or axle by a spring and internal pressure. Quite different from an O-ring.

I think you are right if Omega don`t need that extra seal it must be for redundancy. Tri-lock or what they call it, sounds good in marketing though. I would have been comforted by that fact I think.

I think you have misunderstood my point. I wasn't saying that they all use O-rings (although many do) but that they use a radial or piston seal design. This is why it this design has the name piston seal...

Back in my engineering days I worked with many cylinders, from 1 inch bore up to 30 inch bore. They can use a variety of different seals, but often they were just simple O-rings, depending on the application.

Dan S

·Most people use common sense to turn the crown until it feels snug without forcing it. I think the OP will need to do the same thing.