- Posts

- 25,980

- Likes

- 27,613

ulackfocus

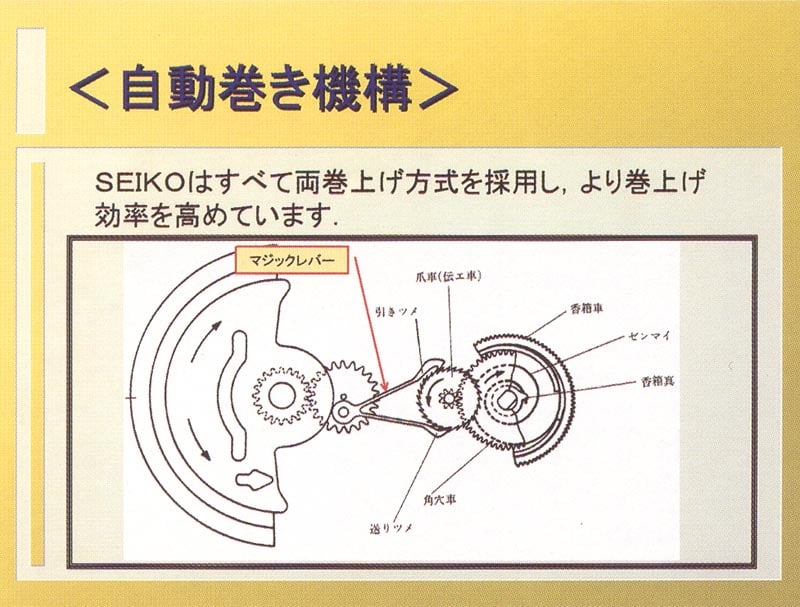

·There are several different full-rotor winding mechanisms in use today; this is a breakdown of one bi-directional system using a mechanical reverser. Since a reverser can change directions over a million times a year in a daily worn wristwatch it must meet the following criteria:

- long lifespan

- low maintenance

- ability to withstand shock

- small dimensions

- flat profile

- simple design with minimal parts

- low friction

- low moment of release (can easily change directions)

- low moment of rotation (amount of energy require to set in motion)

Here's a diagram of the winding mechanism:

1 - crown wheel

2 - intermediate wheel

3 - auxiliary intermediate wheel

4 - ratchet

5 - ratchet-driving pinion

6 - 3-arm spring

7 - ratchet-driving wheel

8 - reduction wheel & pinion

9 - winding wheel & pinion

10 - stop pawl

11 - stop pawl spring

12 - reverser

13 - reverser

14 - pivoting mobile platform

15 - intermediate pinion

16 - oscillating weight pinion

17 - oscillating weight (rotor)

18 - winding stem

19 - winding pinion

CW = clockwise / CCW = counter clockwise

When the rotor (17) spins CW it causes the pinion (15) to revolve CCW. This causes one reverser (13) to spin CW, while the rotational force of the pinion (15) pushes the pivoting mobile platform (14) to swivel so the reverser (13) contacts the winding wheel (9) and spins (9) CCW. The other reverser (12) is useless in this configuration - it rotates freely in a CCW direction without contacting the winding wheel (9).

When the rotor (17) spins CCW it causes the pinion (15) to revolve CW. This causes the reverser (13) to spin CCW which in turn causes the other reverser (12) to spin CW, and the rotational force of the pinion (15) spinning CW swivels the pivoting mobile platform (14) so that the reverser (12) contacts the winding wheel (9) and spins (9) CCW.

Either way the rotor spins, the winding wheel (9) revolves CCW. The stop pawl (10) prevents the winding wheel (9) from ever spinning CW and unwinding the mainspring. The winding wheel (9) drives the reduction wheel (8), which rotates the ratchet-driving wheel (7), which in turn drives the 3 arm spring (6) and ratchet-driving pinion (5). This rotates the ratchet (4) CW and winds the mainspring.

For manual winding, the 3-arm spring (6) comes out of it's holes in the ratchet-driving wheel (7) which uncouples the automatic winding system. The crown is attached to the winding stem (18) which spins CCW, causing the winding pinion (19) to spin CCW. This spins the crown wheel (1) CCW which causes the intermediate wheel (2) to spin CW. The rotational force of the intermediate wheel (2) pushes the auxiliary intermediate wheel (3) to contact the ratchet (4), while the auxiliary intermediate wheel (3) spins CCW and makes the ratchet (4) rotate CW and wind the mainspring. The auxiliary intermediate wheel (3) only contacts the ratchet (4) when it is pushed by the intermediate wheel (2) - it will slide to it's resting position (as shown in the diagram) when the crown is stationary or twisted in the opposite direction.

* All descriptions of motion are based on the watch being positioned dial up & crown pointing away from you. If the crown is facing towards you like so:

it reverses your perspective and would make manual winding a CW twist.

For every complete 360˚ revolution the ratchet (4) completes, the rotor (17) needs to spin between 110 to 180 times. It's easy to see why your watchwinder needs to make so many turns per day to keep your watch wound.

- long lifespan

- low maintenance

- ability to withstand shock

- small dimensions

- flat profile

- simple design with minimal parts

- low friction

- low moment of release (can easily change directions)

- low moment of rotation (amount of energy require to set in motion)

Here's a diagram of the winding mechanism:

1 - crown wheel

2 - intermediate wheel

3 - auxiliary intermediate wheel

4 - ratchet

5 - ratchet-driving pinion

6 - 3-arm spring

7 - ratchet-driving wheel

8 - reduction wheel & pinion

9 - winding wheel & pinion

10 - stop pawl

11 - stop pawl spring

12 - reverser

13 - reverser

14 - pivoting mobile platform

15 - intermediate pinion

16 - oscillating weight pinion

17 - oscillating weight (rotor)

18 - winding stem

19 - winding pinion

CW = clockwise / CCW = counter clockwise

When the rotor (17) spins CW it causes the pinion (15) to revolve CCW. This causes one reverser (13) to spin CW, while the rotational force of the pinion (15) pushes the pivoting mobile platform (14) to swivel so the reverser (13) contacts the winding wheel (9) and spins (9) CCW. The other reverser (12) is useless in this configuration - it rotates freely in a CCW direction without contacting the winding wheel (9).

When the rotor (17) spins CCW it causes the pinion (15) to revolve CW. This causes the reverser (13) to spin CCW which in turn causes the other reverser (12) to spin CW, and the rotational force of the pinion (15) spinning CW swivels the pivoting mobile platform (14) so that the reverser (12) contacts the winding wheel (9) and spins (9) CCW.

Either way the rotor spins, the winding wheel (9) revolves CCW. The stop pawl (10) prevents the winding wheel (9) from ever spinning CW and unwinding the mainspring. The winding wheel (9) drives the reduction wheel (8), which rotates the ratchet-driving wheel (7), which in turn drives the 3 arm spring (6) and ratchet-driving pinion (5). This rotates the ratchet (4) CW and winds the mainspring.

For manual winding, the 3-arm spring (6) comes out of it's holes in the ratchet-driving wheel (7) which uncouples the automatic winding system. The crown is attached to the winding stem (18) which spins CCW, causing the winding pinion (19) to spin CCW. This spins the crown wheel (1) CCW which causes the intermediate wheel (2) to spin CW. The rotational force of the intermediate wheel (2) pushes the auxiliary intermediate wheel (3) to contact the ratchet (4), while the auxiliary intermediate wheel (3) spins CCW and makes the ratchet (4) rotate CW and wind the mainspring. The auxiliary intermediate wheel (3) only contacts the ratchet (4) when it is pushed by the intermediate wheel (2) - it will slide to it's resting position (as shown in the diagram) when the crown is stationary or twisted in the opposite direction.

* All descriptions of motion are based on the watch being positioned dial up & crown pointing away from you. If the crown is facing towards you like so:

it reverses your perspective and would make manual winding a CW twist.

For every complete 360˚ revolution the ratchet (4) completes, the rotor (17) needs to spin between 110 to 180 times. It's easy to see why your watchwinder needs to make so many turns per day to keep your watch wound.