Homemade knives

- Posts

- 8

- Likes

- 20

Cjtamu

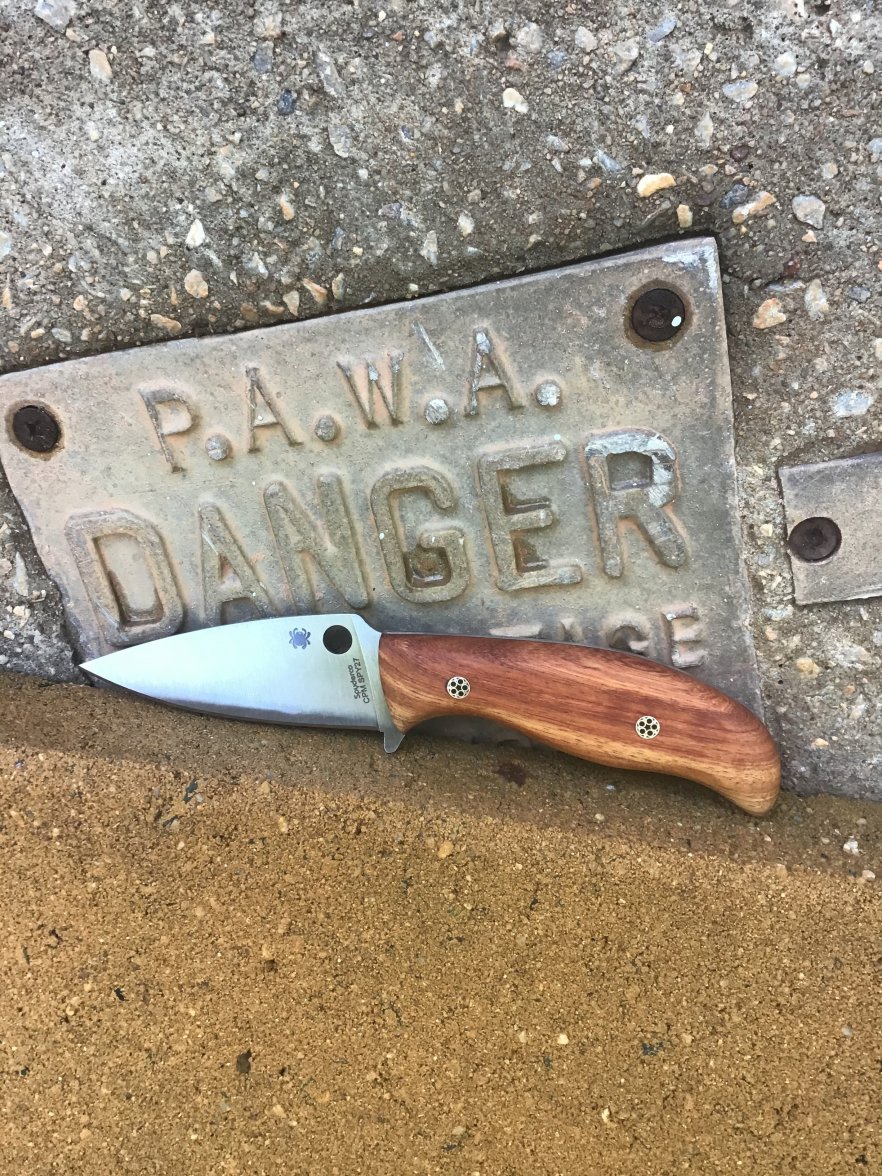

·That Damascus steel is beautiful. Is that Grenadill wood or ebony?

Andsan

·Thanks

I agree with you. Damascus steel is fine. The shaft is made of ebony.

I agree with you. Damascus steel is fine. The shaft is made of ebony.

STANDY

··schizophrenic pizza orderer and watch collectorBlackTalon

··This Space for RentSTANDY

··schizophrenic pizza orderer and watch collectorDamasteel?

Although I do have a good Damascus maker locally that supplies a lot of Damascus steel to Australian knife makers. And has made a few knives for me.

Below is a his and hers in buffalo horn and camel bone. Mrs STANDY claimed the camel bone the second I got home.

This is a newer spin on Damascus for camp and outdoor knives….

Damascus or "forge welded" steel consists of different types of steel heated to welding temperatures and mashed together until they form one steel. The billet is then drawn out, cut or folded. The process is repeated again and again, every time doubling the number of layers.

To get a consistent, strong edge these pieces consist of softer stainless layers over a hard single steel centre edge piece. Basically forge welding the damascus to a VG10. The billet is ready to grind into a blade and is 3 mm x 30 mm x 220 mm in size.

The Damascus billet is heat treated completely, hardened and tempered to 58 HRC. This is a good hardness for outdoor knives as well as general duty kitchen knives.

JimInOz

··Melbourne AustraliaHas anyone done any restorations of old high quality blades (mainly kitchen knives)?

I've seen a few where the grip was destroyed but the blade was still there and probably better steel than modern stuff.

I've seen a few where the grip was destroyed but the blade was still there and probably better steel than modern stuff.

STANDY

··schizophrenic pizza orderer and watch collectorHas anyone done any restorations of old high quality blades (mainly kitchen knives)?

I've seen a few where the grip was destroyed but the blade was still there and probably better steel than modern stuff.

Like this on a butchers knife

So you want to do your bit for the environment. Reduce Reuse Recycle

The below knife was one of my fathers Butchers knives that has sat in a draw for over 20-30 years in my possession and probably 20+ years in my fathers.

Take a old German made butchers knife. Great steel made in the day, Carbon steel at its best, and even better being a Gustav Emil Ern Blade.

https://www.cooksmill.co.uk/blog/gustav-emil-ern-knives.html

Like this

Cracked handle

and

Turn it into a great knife Again

This is such a nice Hardwood handle

So next time your at a thrift store and see a old butchers knife for a few $$s 😉

A knife like this would cost you at least a couple of hundred dollars with a blade nowhere near as good as the early carbon steel used before WW2 and being one of the last companies to employ highly skilled craftsmen to hand make knives whilst most other companies were mass producing knives

(Henckels and Wustof, who were the largest two competitors to Gustav Emil Ern, started mass producing their knives after World War 2. This lowered the cost of production immensely and made it difficult for Gustav Emil Ern to compete against them.)

BlackTalon

··This Space for RentTo get a consistent, strong edge these pieces consist of softer stainless layers over a hard single steel centre edge piece. Basically forge welding the damascus to a VG10. The billet is ready to grind into a blade and is 3 mm x 30 mm x 220 mm in size.

The Damascus billet is heat treated completely, hardened and tempered to 58 HRC. This is a good hardness for outdoor knives as well as general duty kitchen knives.

STANDY

··schizophrenic pizza orderer and watch collectorThat's just san mai, which has been used for a long time in the japanese knife world. But it is admittedly odd the core is VG10. Usually a carbon steel is used, often in conjunction with stainless steel damascus so you only really need to worry about keeping the edge clean. VG10 is also an odd choice for the core if you want stainless because there are much better stainless steel to use (AEB-L, XHP, etc.) as well as some of the semi-stainless steels.

Yeah it’s a weird one. Picked it up as a really good price on special when I ordered a heap of knife making supplies a few months back. Didn’t really read up on it until after I had it.

Being spoilt for choice with steels lately. Magnacut is a new steel in the buzz lately

Did have a knife commissioned for my 50th from a US maker and he used Z wear

BlackTalon

··This Space for RentMagnacut is one of the steels Larrin Thomas developed. His father is Devin Thomas, one of the best known damascus and kitchen knife makers here in the US. Devin is a longtime contributor to the kitchen knife forums, and Larrin has been active there the last few years. He posts a lot of the stuff he develops for knifesteelnerds on that forum.

Andsan

·Jayrock26v2

·Yeah it’s a weird one. Picked it up as a really good price on special when I ordered a heap of knife making supplies a few months back. Didn’t really read up on it until after I had it.

Being spoilt for choice with steels lately. Magnacut is a new steel in the buzz lately

Did have a knife commissioned for my 50th from a US maker and he used Z wear

proper shaving mirror