sheepdoll

·I am continuing from this thread as this is more of a watchmaking thing.

I have been playing about a lot with 134x quartz movements on the side and on the desk in front of my computer. I keep wanting to write this up, which should probably be a bunch of smaller threads rather than another megathread. Still after hours and hours of research megathreads are easier to write, although take more effort to read and study.

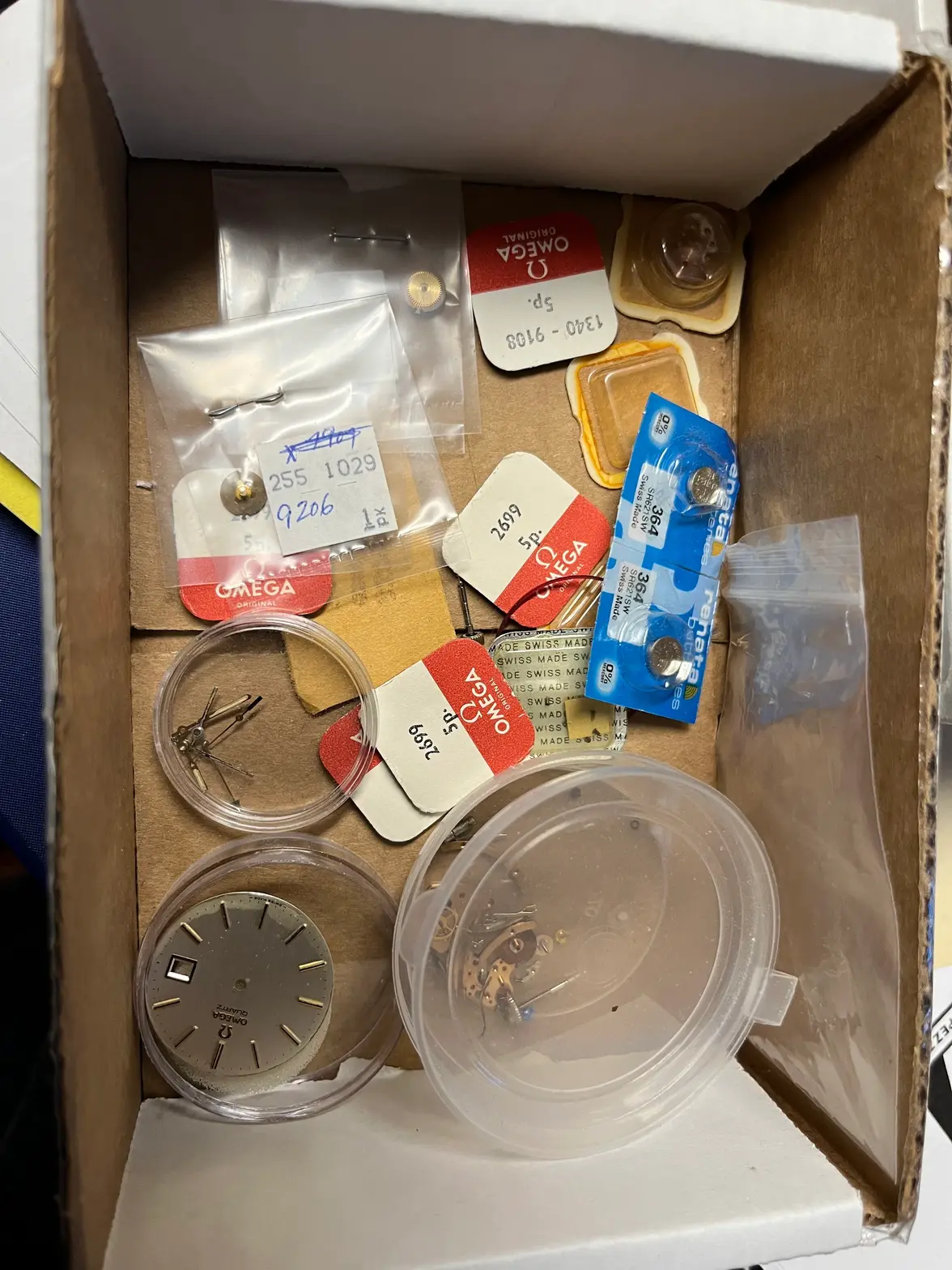

So what we have here are a bunch of quartz watches and cases. Now the dial arrived last night, but I got off on a tangent with an older case which is in the middle left. The case above it and to the upper right are quite similar. These are 196.117 and 168.202 respectivly. Both take plastic movement rings.

Now I was all exited about that beautiful 1345 dial I got which fit a 196.0189/396.0912 case. I just git the remains of the 1345. The dial fit perfectly.

Then I tried to case it but the back fit and the sweep pinion hit the crystal. I then noticed this.

Hell and damnation. The day dial is thicker on the 1345. I also forgot to notice that a 1345 case has the date set button on the side as well since the date does not set via the crown. (The day does set via the crown and that weird mechanical clutch.)

I had laser cut the ring for the dial blank (which is top center and looks like a snowflake.) This also fits nicely but the case can not close as it is too thick. So now I need to make a ring like @ErichKeane is proposing to do. And that only to get a 1342 movement to fit inside the case, so I am back to square one in all of this.

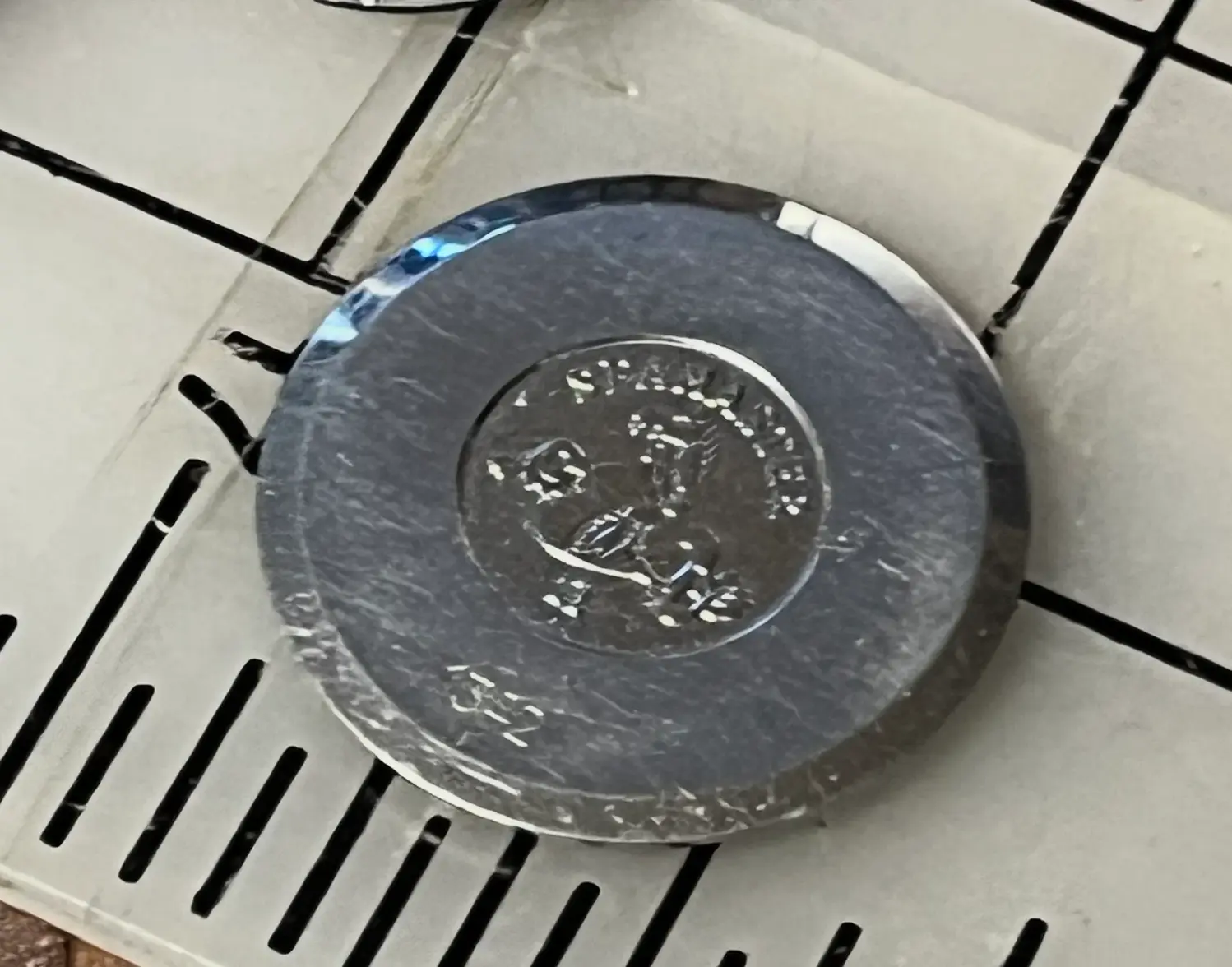

The acrylic spacer ring also is too thick and I cracked it even more swapping it.

I am getting quite a selection of parts screws case clamps and such.

I forgot I had the other bogus dial which clocks in at 29.6 where the dial inset in the 168.202 is closer to 28.5. moot point as that really takes a 1010/1012 according to the vintage site. It does however make me speculate if there was the feeling during the quartz crisis to make these movements interchangeable. Since the sentimental value is in the case. In the quoted thread someone had jammed a quarts movement into a cocktail watch.

The thing though with making gaskets or even dial blanks, is that just one can not be made.

Even with the laser it take some trial and error to get the scaling and kerf just right. I did make some acrylic guides, so could probably turn down the blanks with the lathe. A lot of dials are domed, so that means coming up with a way to spin them or stamp them.

This still remains a side project onto a tangent through a rabbit hole but it simply is so dammed interesting.

I did have more luck with movement holders for the 55x movements, but that is another thread. I think these were noted elsewhere in various comments and things. I also have some threads for restricting the electronics and such.

At the moment there is enough of legacy materials out in the wild so making new things is still a little on the early side. It also goes against the club collector spirit what drives the passion.

These are actually more than JUST gaskets, they are full-size things with shapes/etc.Yeah most of them wound up in the 🔥❤️🔥🔥fiery furnace.🔥❤️🔥🔥It is hard to keep track of all these ladies calibers. They were a lot of the bread and butter before the quartz crisis. What paied for the R&D. The 470/480 is not the smallest auto. The 455 is 16mm and automatic. I have some rectangular 730 movements what fell into my shoe, and I walked around for the better part of a day till I felt the lump Surprisingly the balances still twitch.The main problem with these wonderful watches is as noted they were melted down. Most were probably gifts only worn once, which is why they were such the cash cow back in the day.The makerspace recently got a new 3D printer that is a lot easier to use. I had some decent results using the laser to cut acrylic, but the acrylic is brittle. Did a bit with silicone RTV for mold making. Might be possible to use the laser to make a mold and cast some RTV. Gaskets are an issue why I never totally finish my projects. One of which is a shot injection molding press.

Here's a pic of the gaskets I have. They are in reasonable shape, and I might just re-use them, but they have some gouges from a previous watchmaker trying to dig them out (I got this watch as 'used' with no idea what was IN it thanks to said seller not being able to get into it!).

I DID pick up a piece of what I think is the best match, some 95A Polyurethane round rod, but could only find it in... a large size and didn't conceptualize how big it is It should only take a little time to make each piece on the lathe, but I have to get out ot my shop, and its cold these days (Ed White for scale, note that the bracelet while open only BARELY fits! 2.5" diameter!).

I have been playing about a lot with 134x quartz movements on the side and on the desk in front of my computer. I keep wanting to write this up, which should probably be a bunch of smaller threads rather than another megathread. Still after hours and hours of research megathreads are easier to write, although take more effort to read and study.

So what we have here are a bunch of quartz watches and cases. Now the dial arrived last night, but I got off on a tangent with an older case which is in the middle left. The case above it and to the upper right are quite similar. These are 196.117 and 168.202 respectivly. Both take plastic movement rings.

Now I was all exited about that beautiful 1345 dial I got which fit a 196.0189/396.0912 case. I just git the remains of the 1345. The dial fit perfectly.

Then I tried to case it but the back fit and the sweep pinion hit the crystal. I then noticed this.

Hell and damnation. The day dial is thicker on the 1345. I also forgot to notice that a 1345 case has the date set button on the side as well since the date does not set via the crown. (The day does set via the crown and that weird mechanical clutch.)

I had laser cut the ring for the dial blank (which is top center and looks like a snowflake.) This also fits nicely but the case can not close as it is too thick. So now I need to make a ring like @ErichKeane is proposing to do. And that only to get a 1342 movement to fit inside the case, so I am back to square one in all of this.

The acrylic spacer ring also is too thick and I cracked it even more swapping it.

I am getting quite a selection of parts screws case clamps and such.

I forgot I had the other bogus dial which clocks in at 29.6 where the dial inset in the 168.202 is closer to 28.5. moot point as that really takes a 1010/1012 according to the vintage site. It does however make me speculate if there was the feeling during the quartz crisis to make these movements interchangeable. Since the sentimental value is in the case. In the quoted thread someone had jammed a quarts movement into a cocktail watch.

The thing though with making gaskets or even dial blanks, is that just one can not be made.

Even with the laser it take some trial and error to get the scaling and kerf just right. I did make some acrylic guides, so could probably turn down the blanks with the lathe. A lot of dials are domed, so that means coming up with a way to spin them or stamp them.

This still remains a side project onto a tangent through a rabbit hole but it simply is so dammed interesting.

I did have more luck with movement holders for the 55x movements, but that is another thread. I think these were noted elsewhere in various comments and things. I also have some threads for restricting the electronics and such.

At the moment there is enough of legacy materials out in the wild so making new things is still a little on the early side. It also goes against the club collector spirit what drives the passion.

Edited: