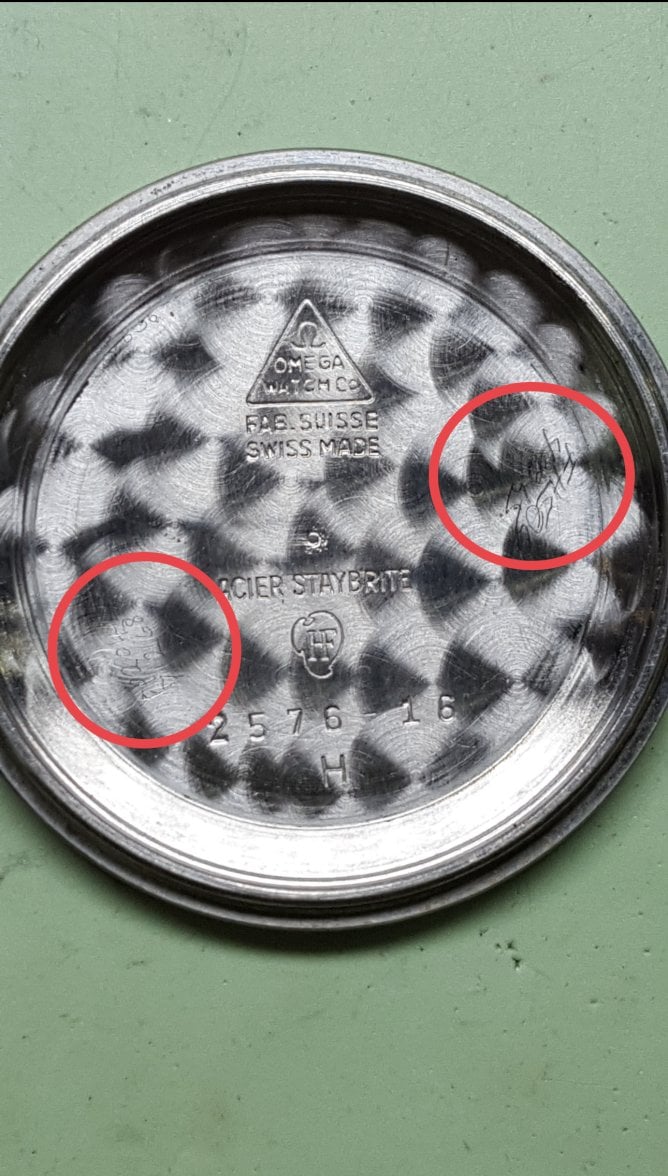

CBM1590

· ·We don’t rent pigs.Howdy all! My watchmaker sent me these pics of the inside of my old Seamaster bumper that is undergoing complete service and restoration of broken or worn parts. Serial number is 13196137 and the movement is 342. I’ll have to do some digging to find the date of manufacture.

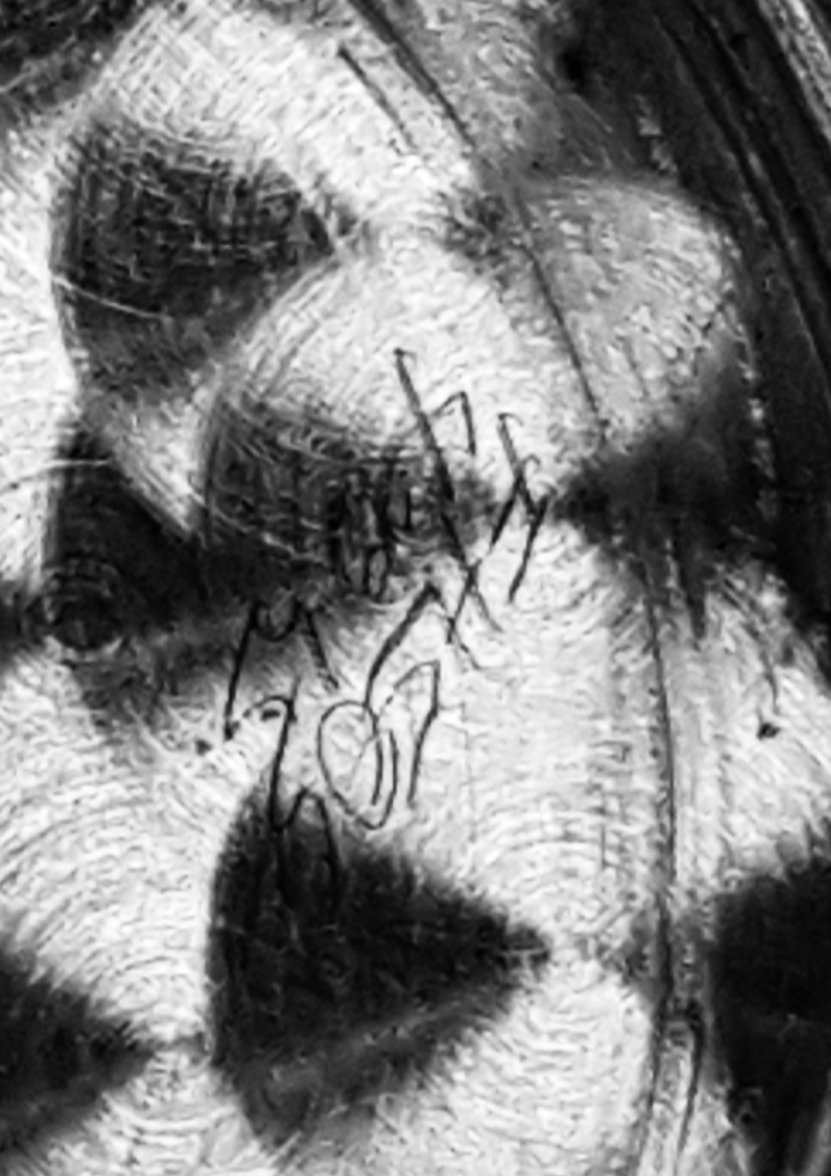

There is a small piece of metal debris visible on the rotor in one of the pics. Further disassembly will reveal what may be broken, however, it did run and keep time for a couple of weeks. That disassembly will occur likely Saturday. What I’ve never told you is that the watch in the lockbox survived the house fire in that totally destroyed my 1889-built home. The watch certainly has a story to tell.

I’d be interested in hearing from you who have expertise regarding what you see (or don’t) in the mechanism. I’ll post the original outside pic for reference as well. Excited to get this restoration project started. Best to you all! CBM

There is a small piece of metal debris visible on the rotor in one of the pics. Further disassembly will reveal what may be broken, however, it did run and keep time for a couple of weeks. That disassembly will occur likely Saturday. What I’ve never told you is that the watch in the lockbox survived the house fire in that totally destroyed my 1889-built home. The watch certainly has a story to tell.

I’d be interested in hearing from you who have expertise regarding what you see (or don’t) in the mechanism. I’ll post the original outside pic for reference as well. Excited to get this restoration project started. Best to you all! CBM