kaplan

·I've stocked quite a bit of 0.18mm seconds hands from a NOS parts dealer, have experience pressing hands, yet I can't press any of the 0.18mm hands I got from this seller. Looking back I've only pressed used seconds hands, so maybe I don't know the process for pressing a new seconds hand

My theories are:

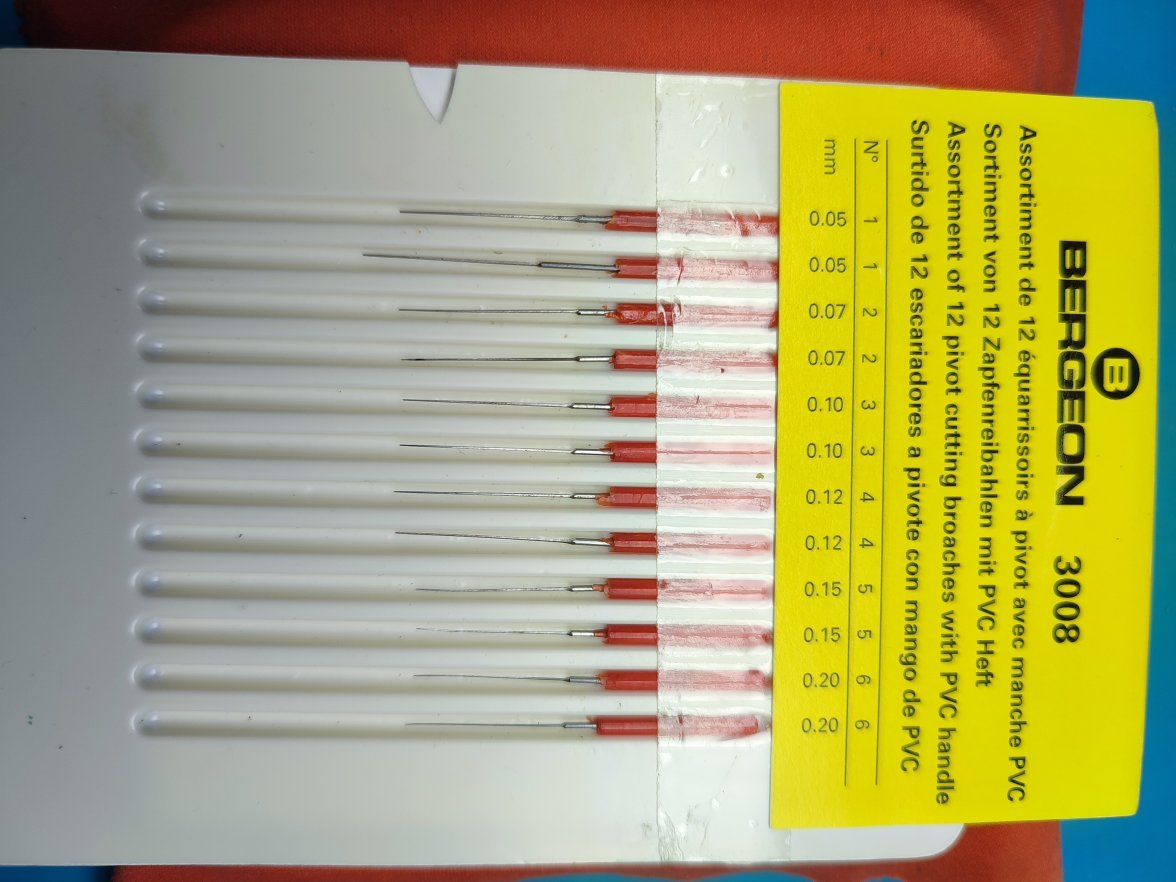

1) I need pivot broaches to smooth them first before using

2) Maybe these are 0.15mm

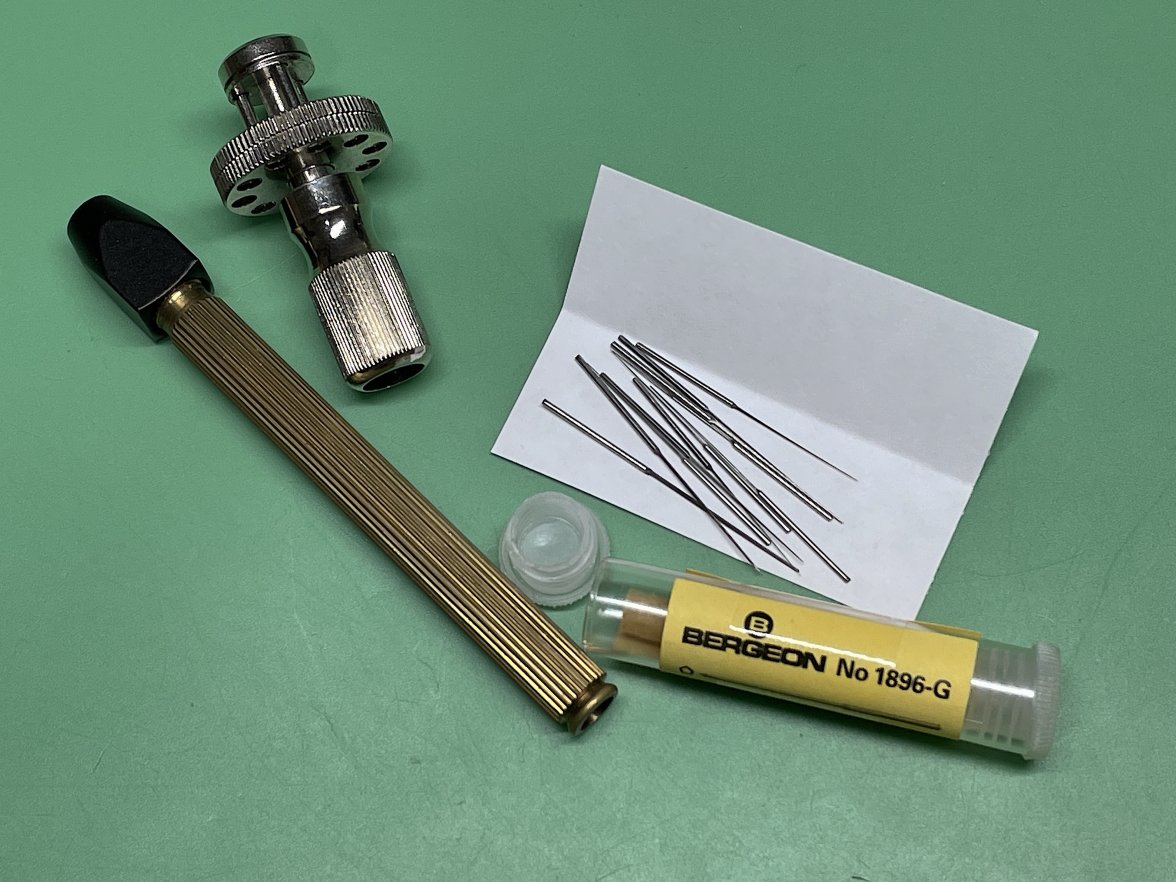

I'm currently looking at Bergeon 1896-H, but it doesn't specify the exact sizes

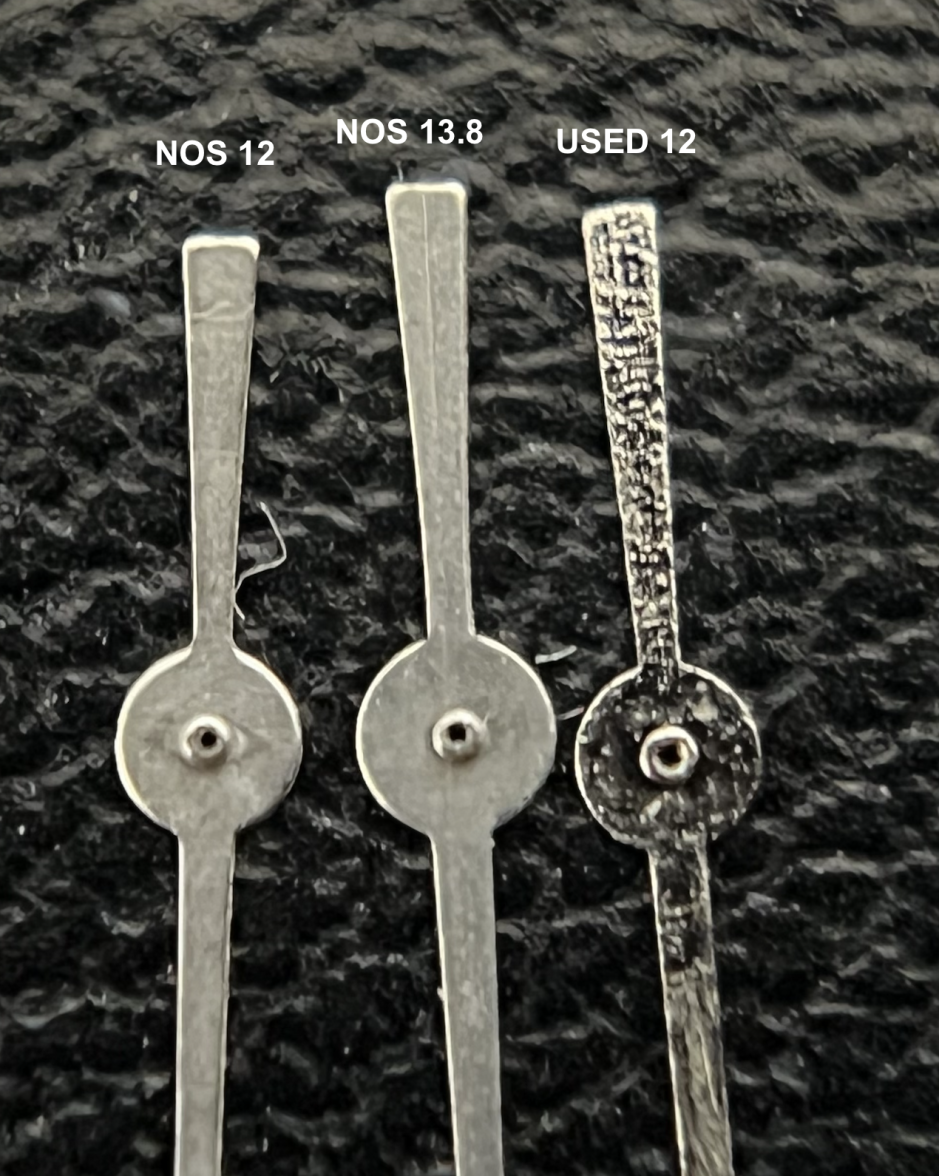

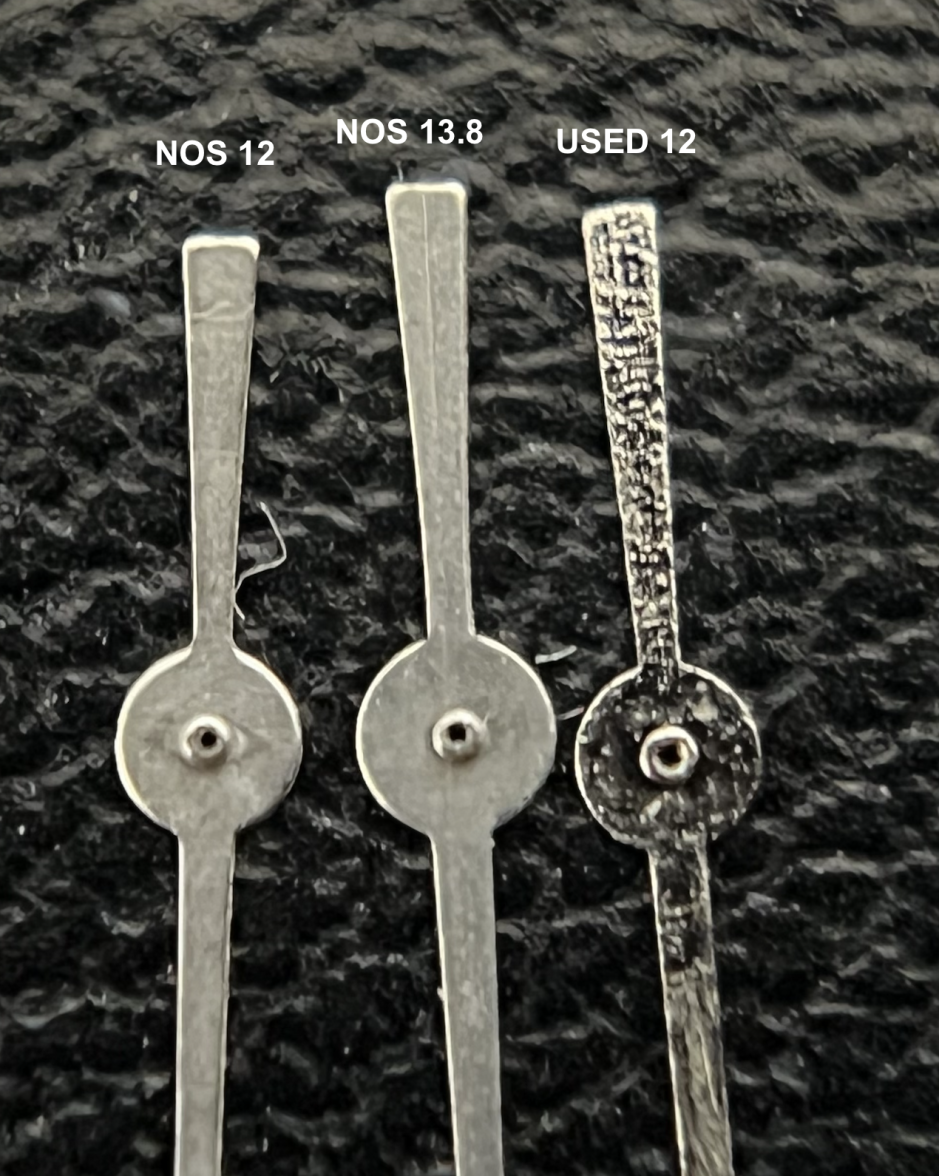

Actually took this macro shot, and I think these aren't 0.18mm

My theories are:

1) I need pivot broaches to smooth them first before using

2) Maybe these are 0.15mm

I'm currently looking at Bergeon 1896-H, but it doesn't specify the exact sizes

Actually took this macro shot, and I think these aren't 0.18mm