- Posts

- 30

- Likes

- 1

Dood

·Good morning to the OF community,

As always, I should thank everybody for the shared knowledge. I have been hanging around here for about a year, it is a gold mine.

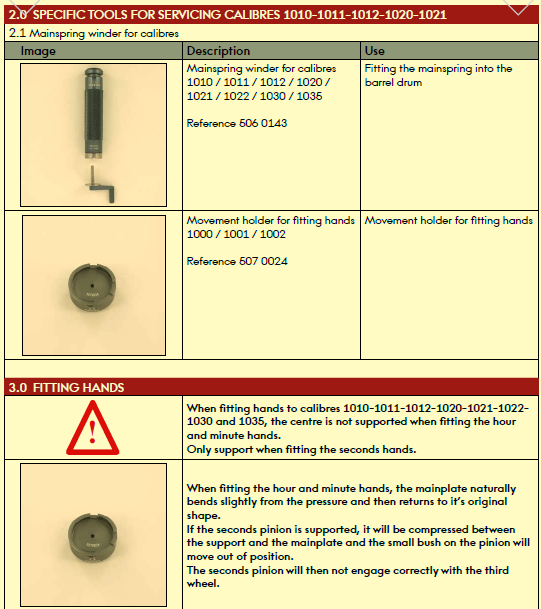

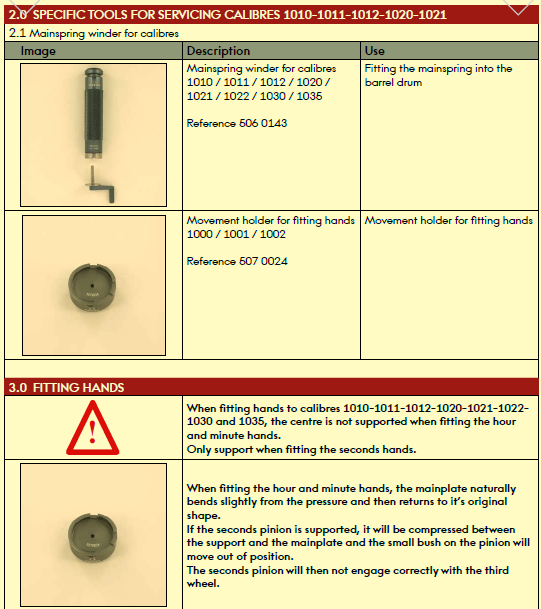

Struggling to fit seconds hand on a 1030 caliber, I looked on the internet and found this:

This specific movement holder does not seem to exist anymore, I turned to Bergeon who still sell a 12 1/2 holder that could do even if it slightly too large. Any tricks from enthusiasts out there to support the seconds pinion and set the hand without this ?

Thanks

Tom

As always, I should thank everybody for the shared knowledge. I have been hanging around here for about a year, it is a gold mine.

Struggling to fit seconds hand on a 1030 caliber, I looked on the internet and found this:

This specific movement holder does not seem to exist anymore, I turned to Bergeon who still sell a 12 1/2 holder that could do even if it slightly too large. Any tricks from enthusiasts out there to support the seconds pinion and set the hand without this ?

Thanks

Tom