Deafcon

··Omega Certified WatchmakerI haven't totally introduced myself, but have been following these forums for a while. I am watch collector of mostly Omega's, though have been getting into some other brands as well. A big part of the hobby for me is the repair side. I started with reading as many books as I could, then took all 4 of the TimeZone online classes. They were good for a start, but I knew I wanted to learn more.

I next attend the Introduction to Watchmaking class at the AWCI, a week long class that covers the 6497 movement, I learned far more in that week then in my previous 2 years of learning on my own.

Next was the AWCI Swiss Lever Escapement class, a good part of that class was diagnosing watches with faults preinstalled by the instructor. It was tough, and I certainly felt humbled at times when I didn't find and correct all the faults.

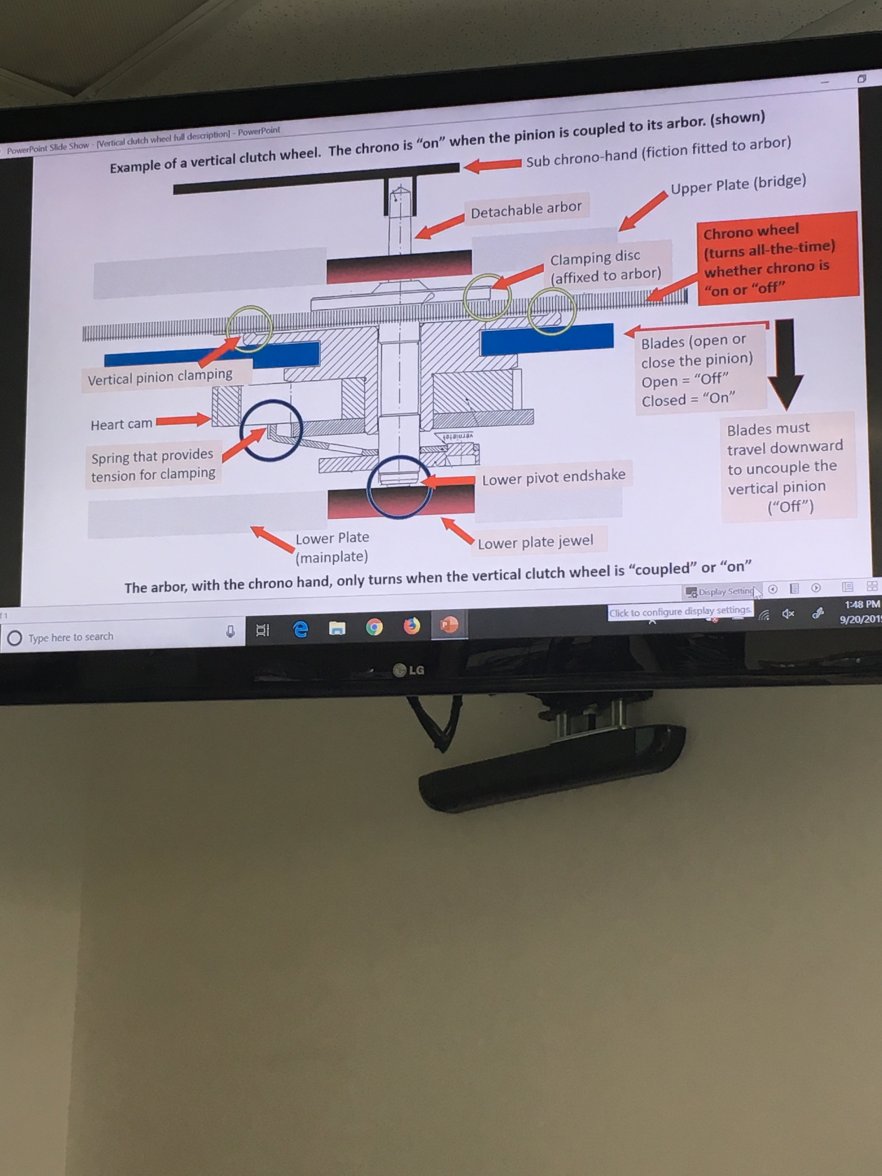

This week is the class I've really been looking forward to, It covers mostly the ETA 7750 and 7751. We only have 3 people in class, so the instructor plans to cover other things as well, one of which is the Lemania 1873, also know as the Omega 861.

Today was theory and history, then adjustment of the chronographs system. I didn't get a lot of pictures as I was too busy learning.

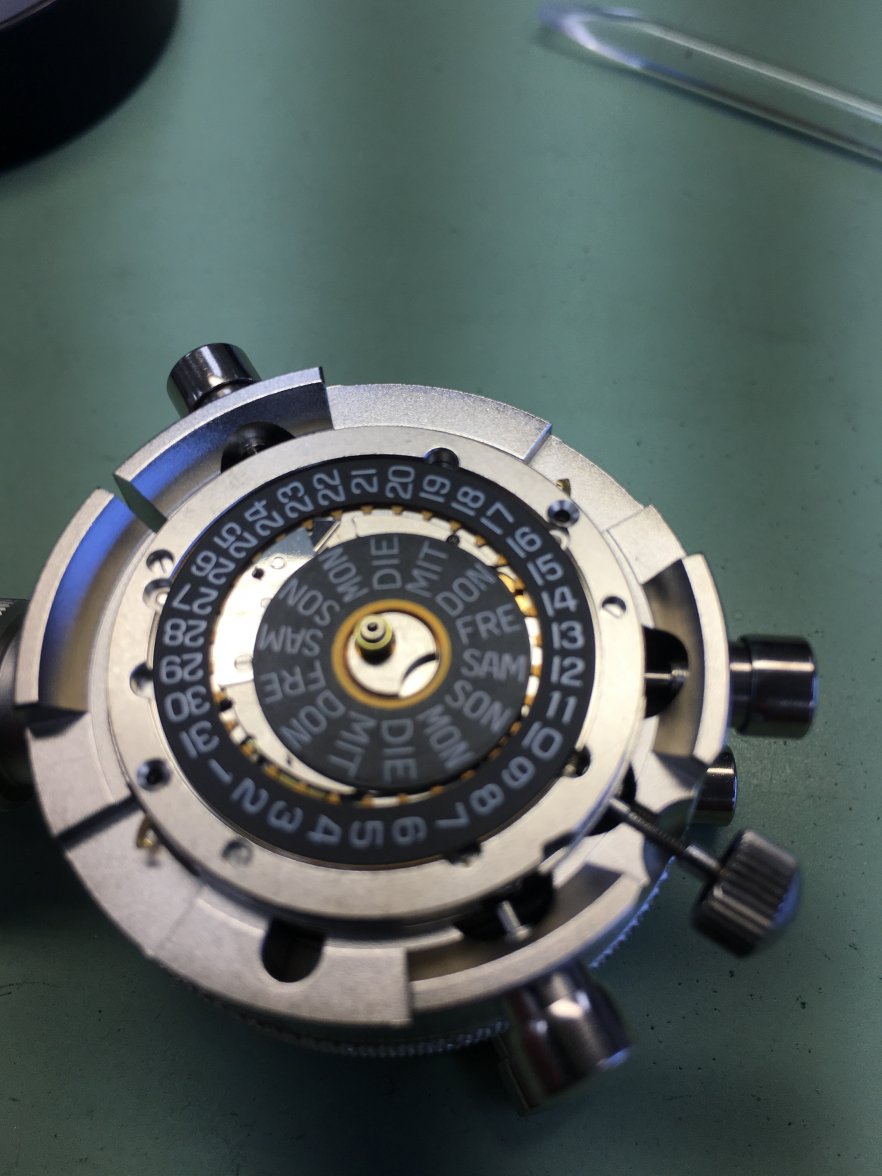

The class provided watch is a Tissot, which has been apart many times. It has scratches, marred up screws, and many other things that shouldn't be happing in a repair shop, though often do based on some of the "serviced" watches i've purchased. I also brought along a Sinn 144 from my collection that doesn't run. So far I've found 3 problems with it, It seems to have had a hard previous life. More on that watch later.

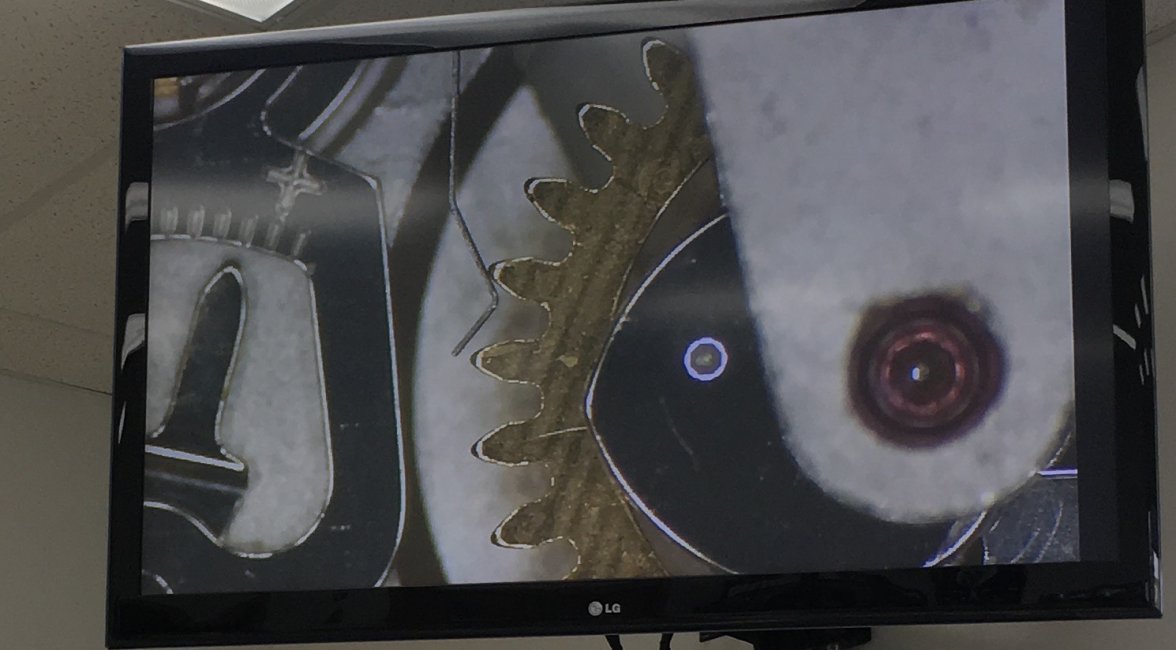

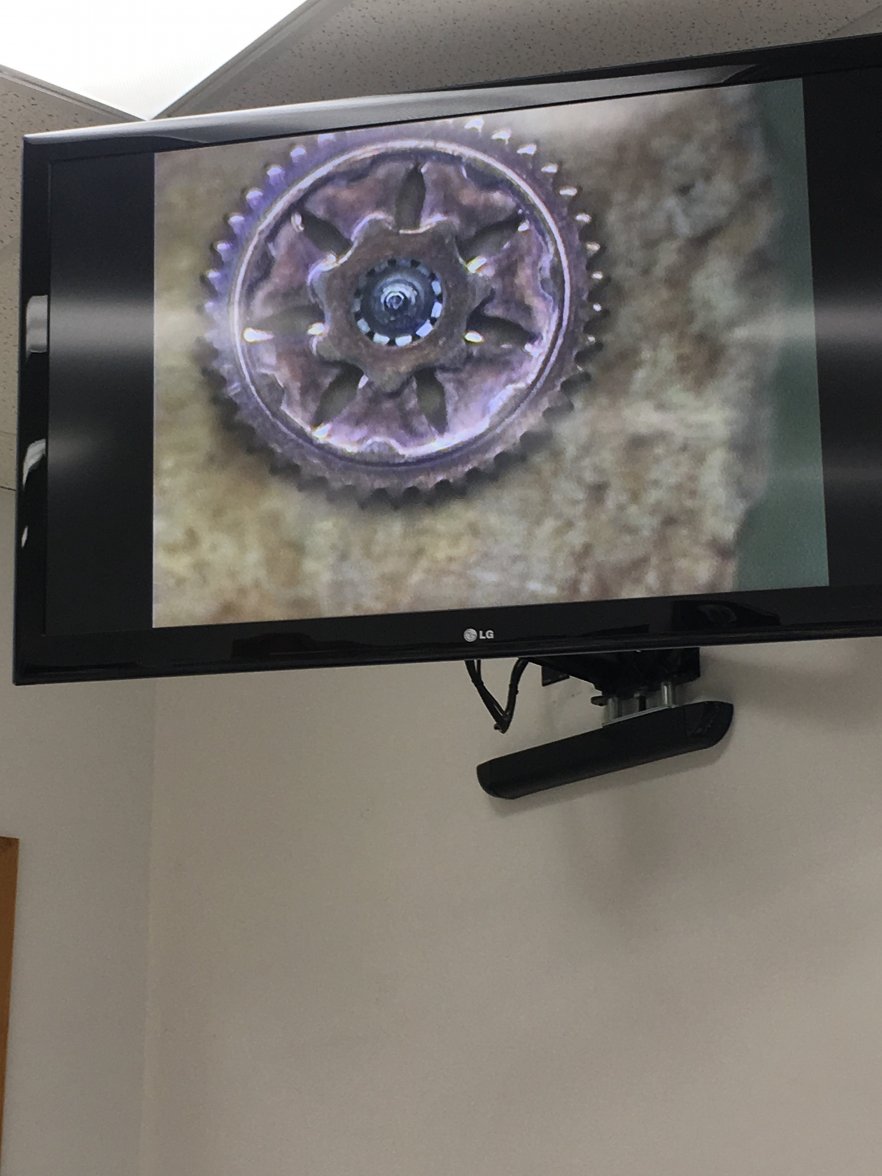

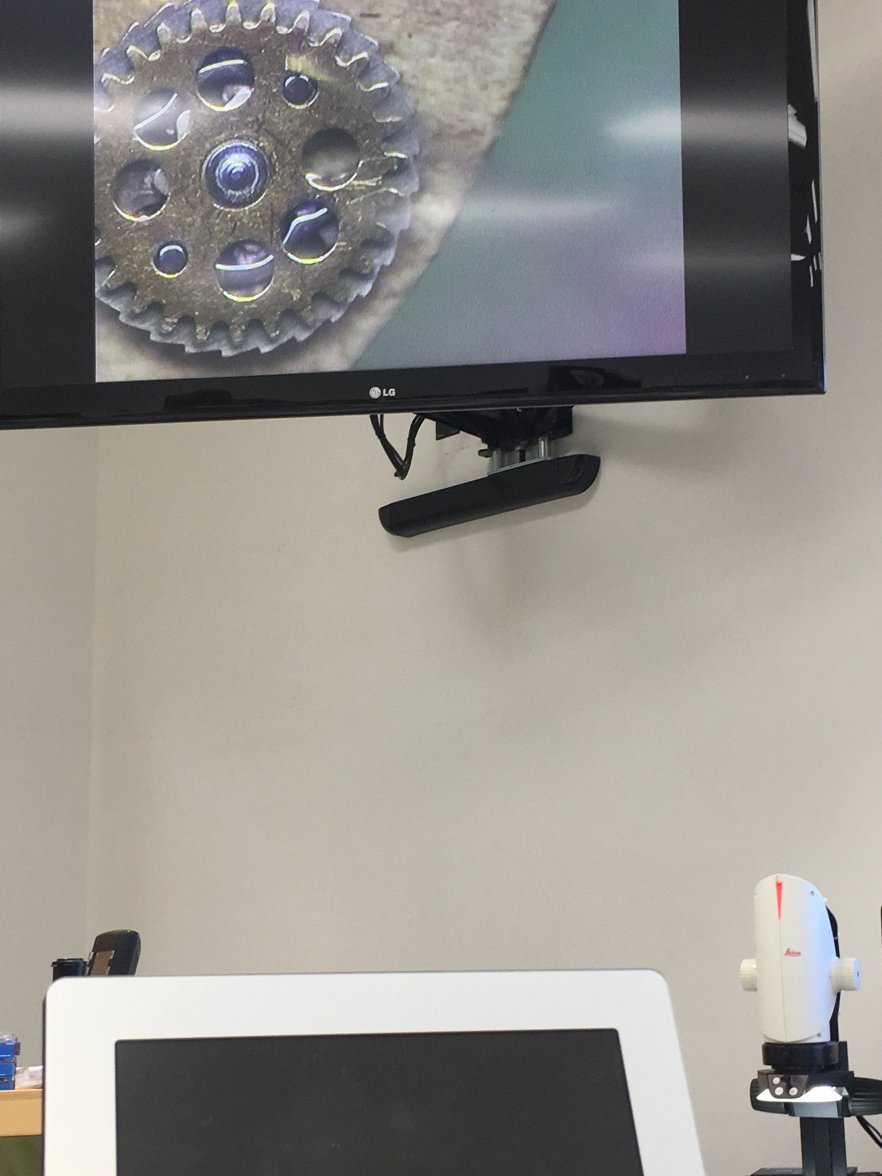

All our work is inspected by Tom, the instructor, under the microscope and displayed for all to see.

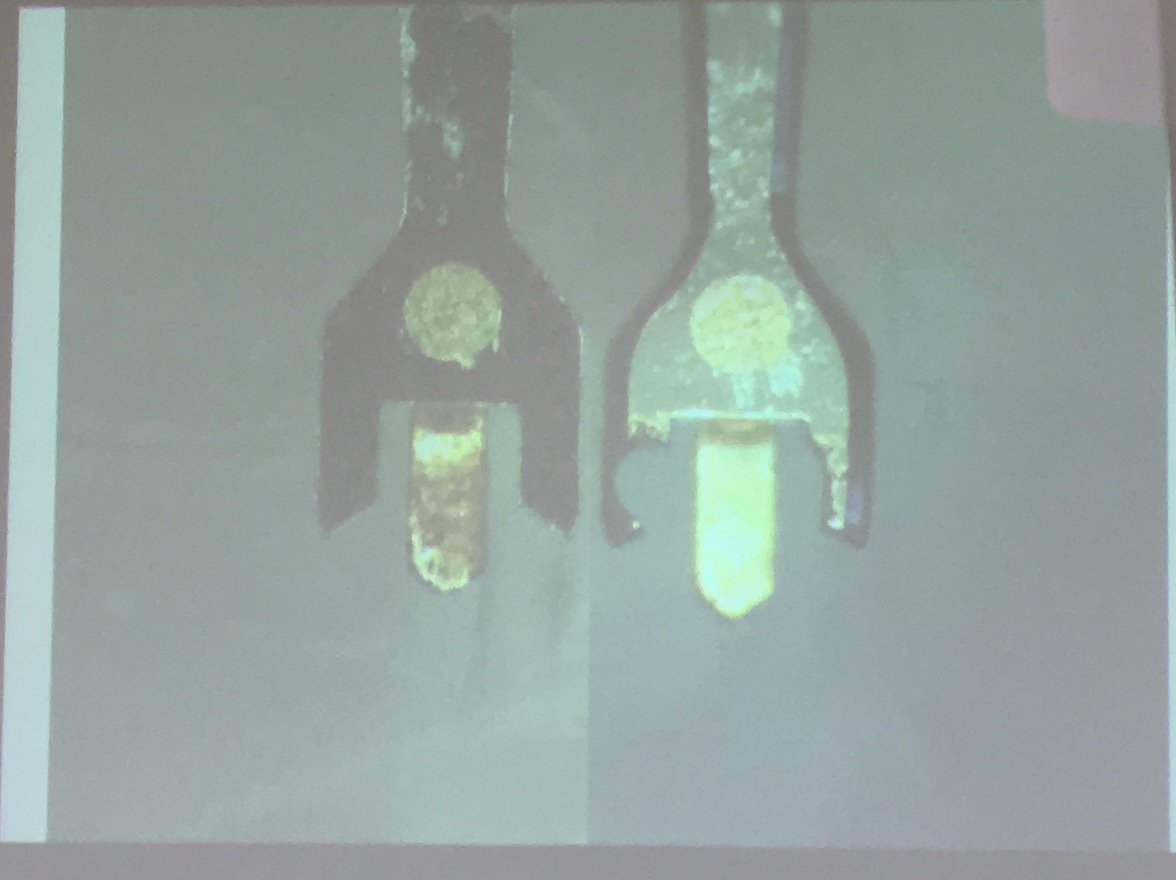

Pictured is a grossly misadjusted minute jumper. With the hammer down on the heart cam of the minute counter, it should be touching two teeth.

<iframe src="https://www.facebook.com/plugins/vi...deos/10157902346092642/&show_text=0&width=560" width="560" height="315" style="border:none;overflow:hidden" scrolling="no" frameborder="0" allowTransparency="true" allowFullScreen="true"></iframe>

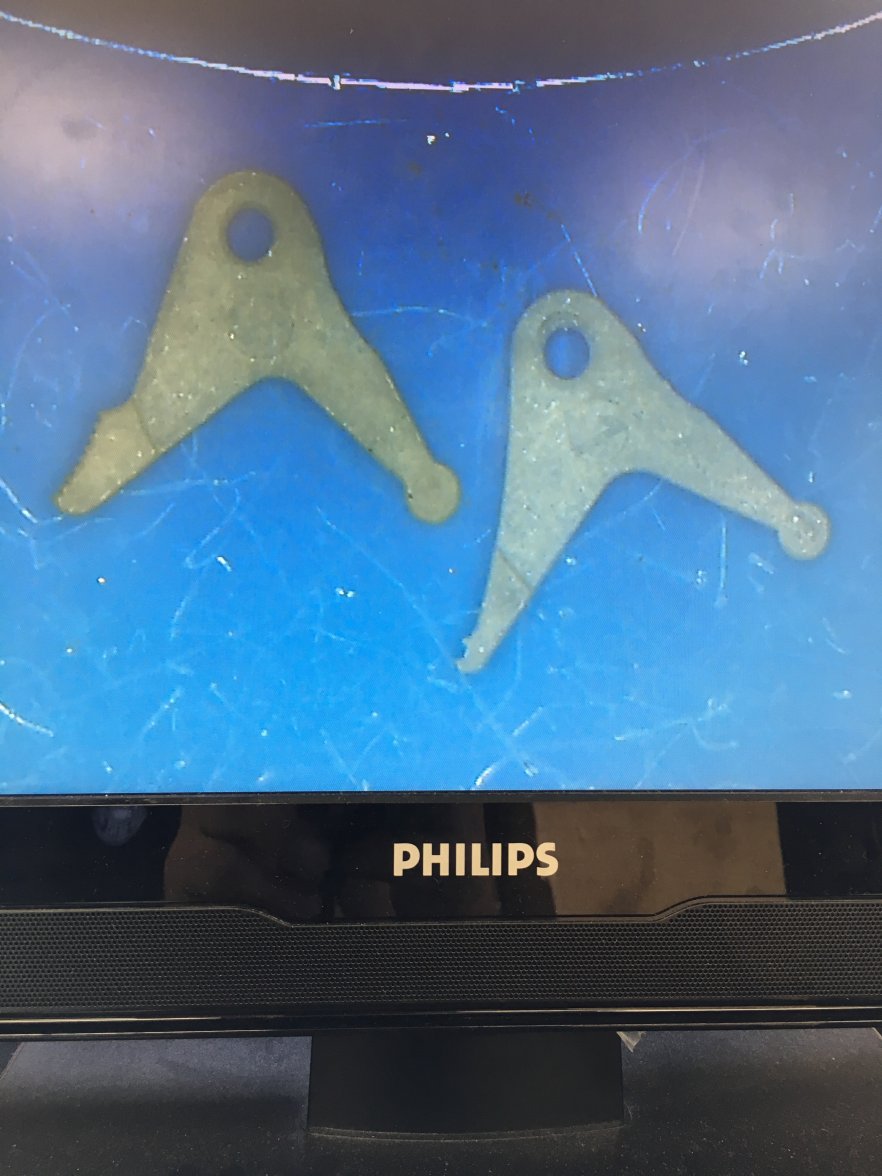

This is a video of the function check of the chronograph wheel jumper "finger". The finger had previously been adjusted at it's beak, which should never be done. I got it adjusted to Tom's approval however. I found its interesting how one of the functions of the finger is to take the slack out between minute counter driving wheel and minute counting wheel, making the minute counter hand jump cleaner when the finger comes back around and starts engaging the minute counter driving wheel at 58 seconds. You can see the slight nudge right after the finger clicks the wheel over one tooth.

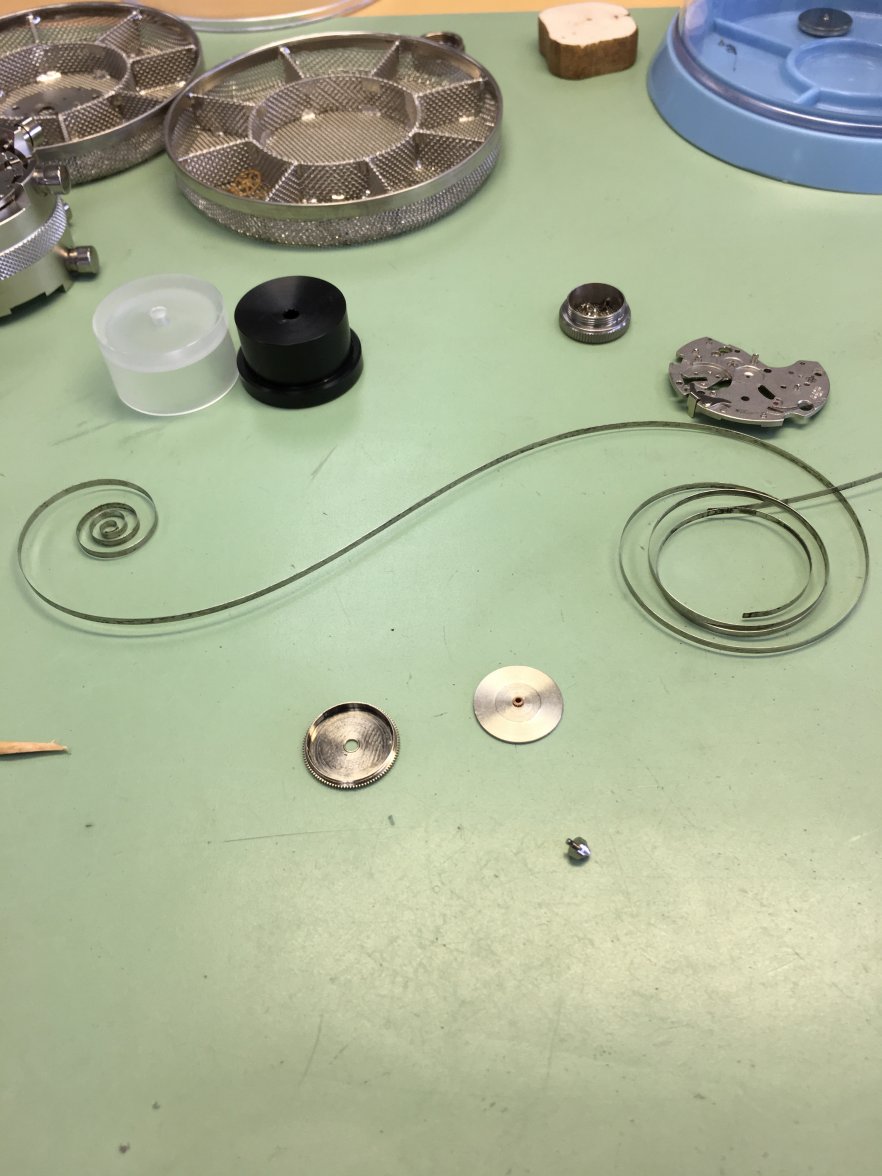

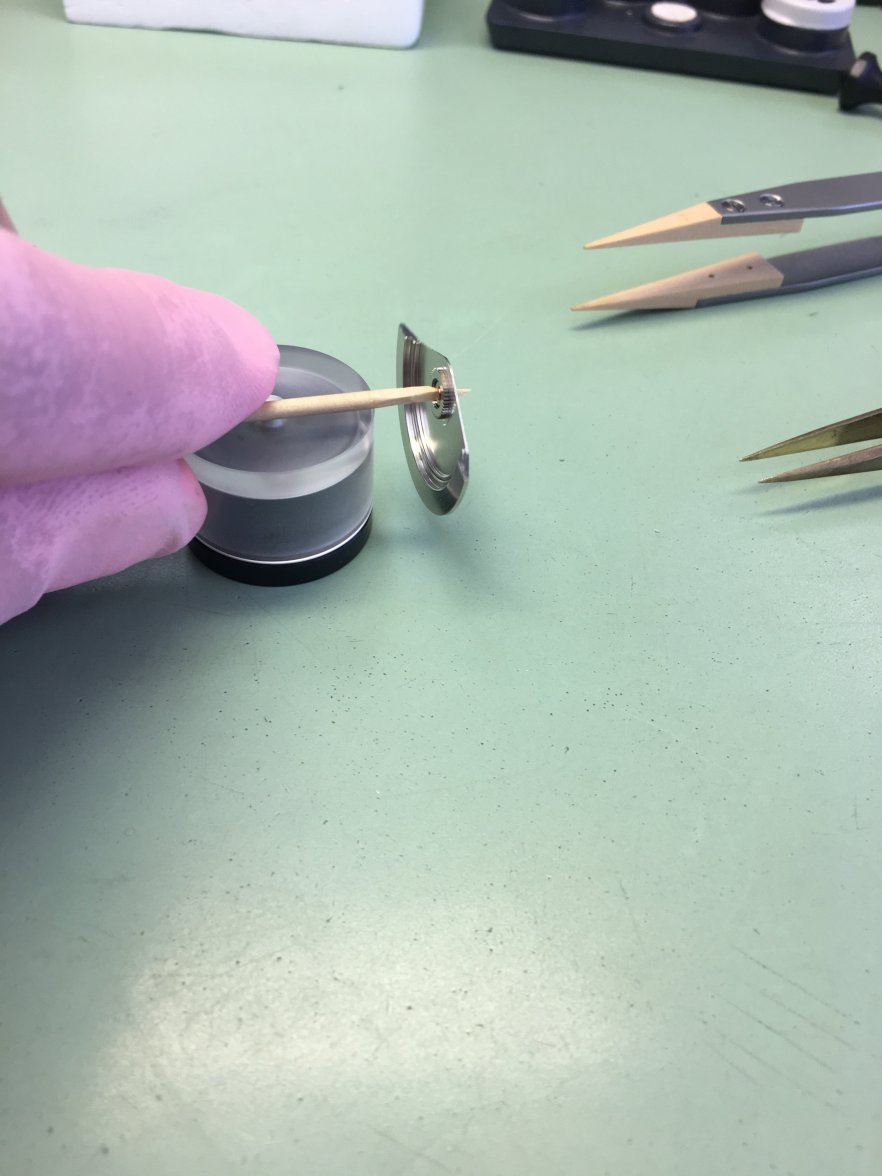

I didn't get any photos of the depthing adjustment of the oscillating pinion, but will do so tomorrow. The engagement depth is 2/3. It must be checked through a full 60 seconds, as the chronograph runners are often not as concentric as you would expect. In the watch I was working on, the 35-50 second range was tighter than the opposite side. More to come tomorrow.

Joe

I next attend the Introduction to Watchmaking class at the AWCI, a week long class that covers the 6497 movement, I learned far more in that week then in my previous 2 years of learning on my own.

Next was the AWCI Swiss Lever Escapement class, a good part of that class was diagnosing watches with faults preinstalled by the instructor. It was tough, and I certainly felt humbled at times when I didn't find and correct all the faults.

This week is the class I've really been looking forward to, It covers mostly the ETA 7750 and 7751. We only have 3 people in class, so the instructor plans to cover other things as well, one of which is the Lemania 1873, also know as the Omega 861.

Today was theory and history, then adjustment of the chronographs system. I didn't get a lot of pictures as I was too busy learning.

The class provided watch is a Tissot, which has been apart many times. It has scratches, marred up screws, and many other things that shouldn't be happing in a repair shop, though often do based on some of the "serviced" watches i've purchased. I also brought along a Sinn 144 from my collection that doesn't run. So far I've found 3 problems with it, It seems to have had a hard previous life. More on that watch later.

All our work is inspected by Tom, the instructor, under the microscope and displayed for all to see.

Pictured is a grossly misadjusted minute jumper. With the hammer down on the heart cam of the minute counter, it should be touching two teeth.

<iframe src="https://www.facebook.com/plugins/vi...deos/10157902346092642/&show_text=0&width=560" width="560" height="315" style="border:none;overflow:hidden" scrolling="no" frameborder="0" allowTransparency="true" allowFullScreen="true"></iframe>

This is a video of the function check of the chronograph wheel jumper "finger". The finger had previously been adjusted at it's beak, which should never be done. I got it adjusted to Tom's approval however. I found its interesting how one of the functions of the finger is to take the slack out between minute counter driving wheel and minute counting wheel, making the minute counter hand jump cleaner when the finger comes back around and starts engaging the minute counter driving wheel at 58 seconds. You can see the slight nudge right after the finger clicks the wheel over one tooth.

I didn't get any photos of the depthing adjustment of the oscillating pinion, but will do so tomorrow. The engagement depth is 2/3. It must be checked through a full 60 seconds, as the chronograph runners are often not as concentric as you would expect. In the watch I was working on, the 35-50 second range was tighter than the opposite side. More to come tomorrow.

Joe